Subject: Undocumented 8086 instructions, explained by the microcode

What happens if you give the Intel 8086 processor an instruction that doesn't exist? A modern microprocessor (80186 and later) will generate an exception, indicating that an illegal instruction was executed. However, early microprocessors didn't include the circuitry to detect illegal instructions, since the chips didn't have transistors to spare. Instead these processors would do something, but the results weren't specified.1

The 8086 has a number of undocumented instructions. Most of them are simply duplicates of regular instructions, but a few have unexpected behavior, such as revealing the values of internal, hidden registers. In the 8086, most instructions are implemented in microcode, so examining the 8086's microcode can explain why these instructions behave the way they do.

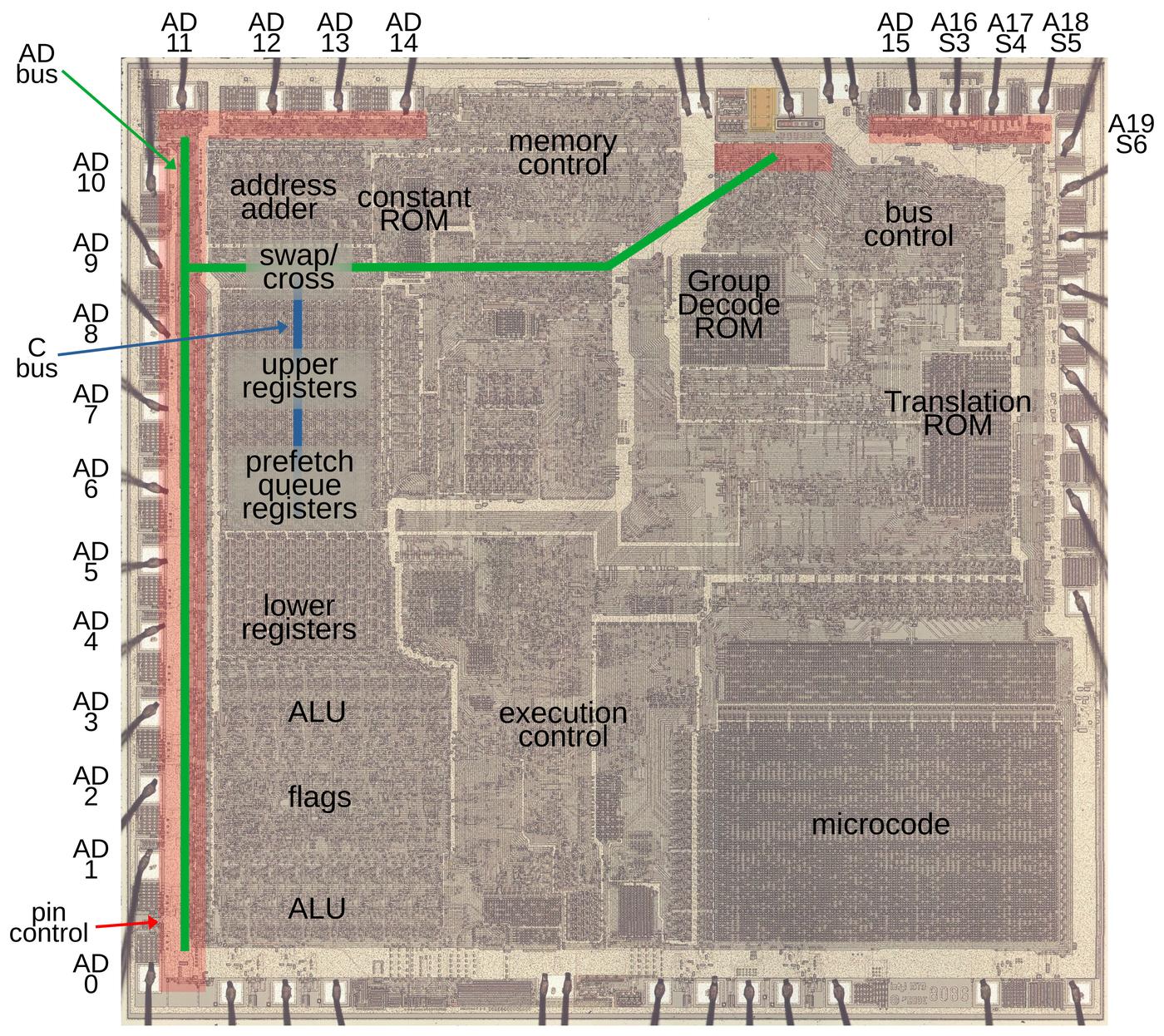

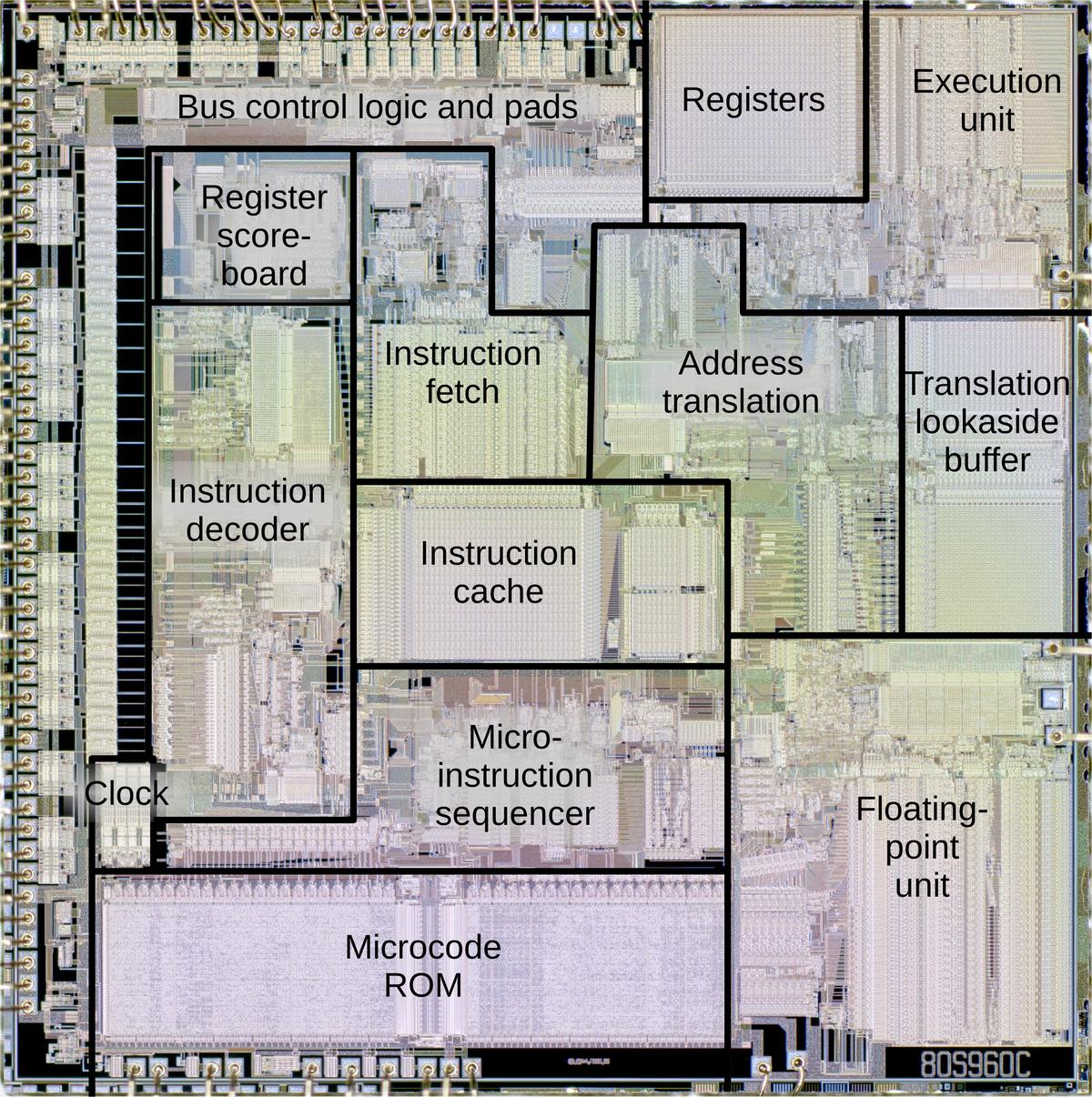

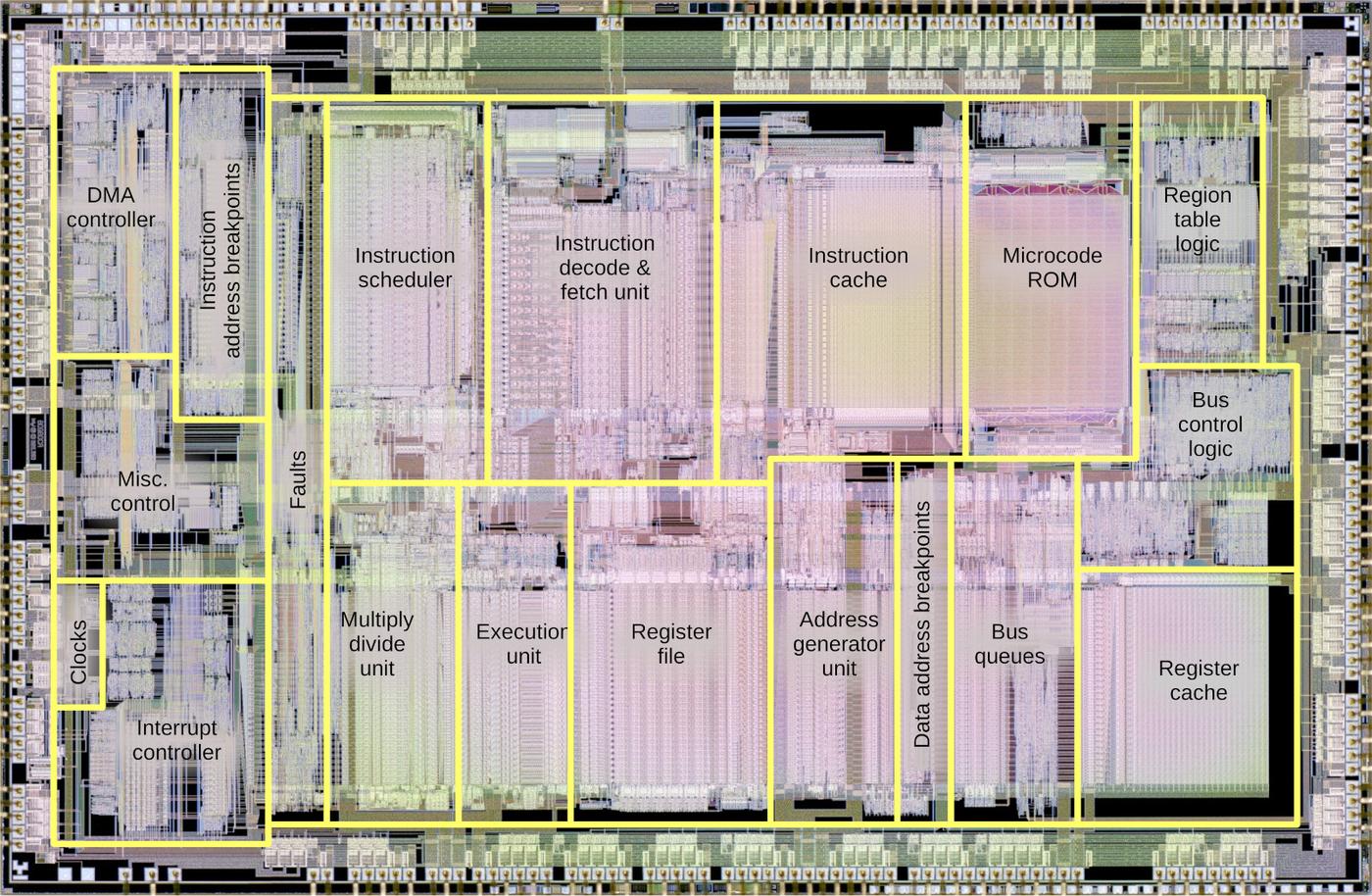

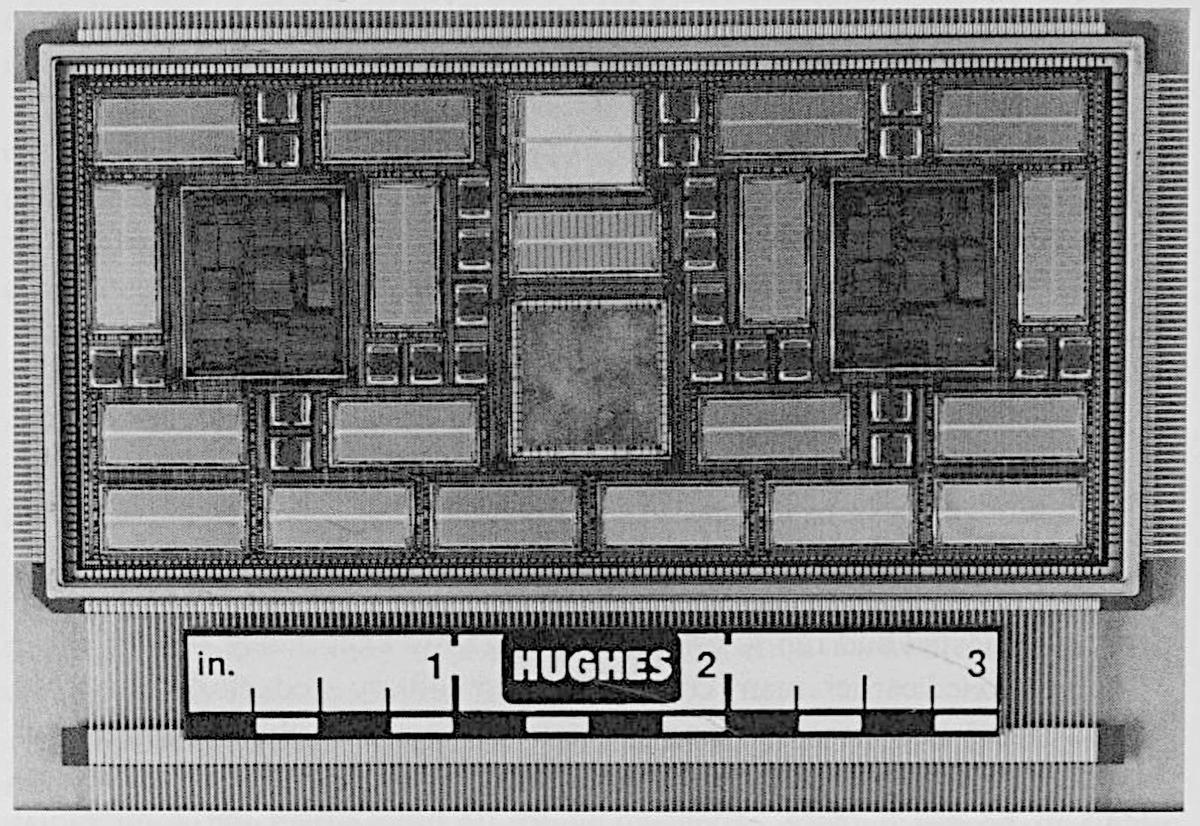

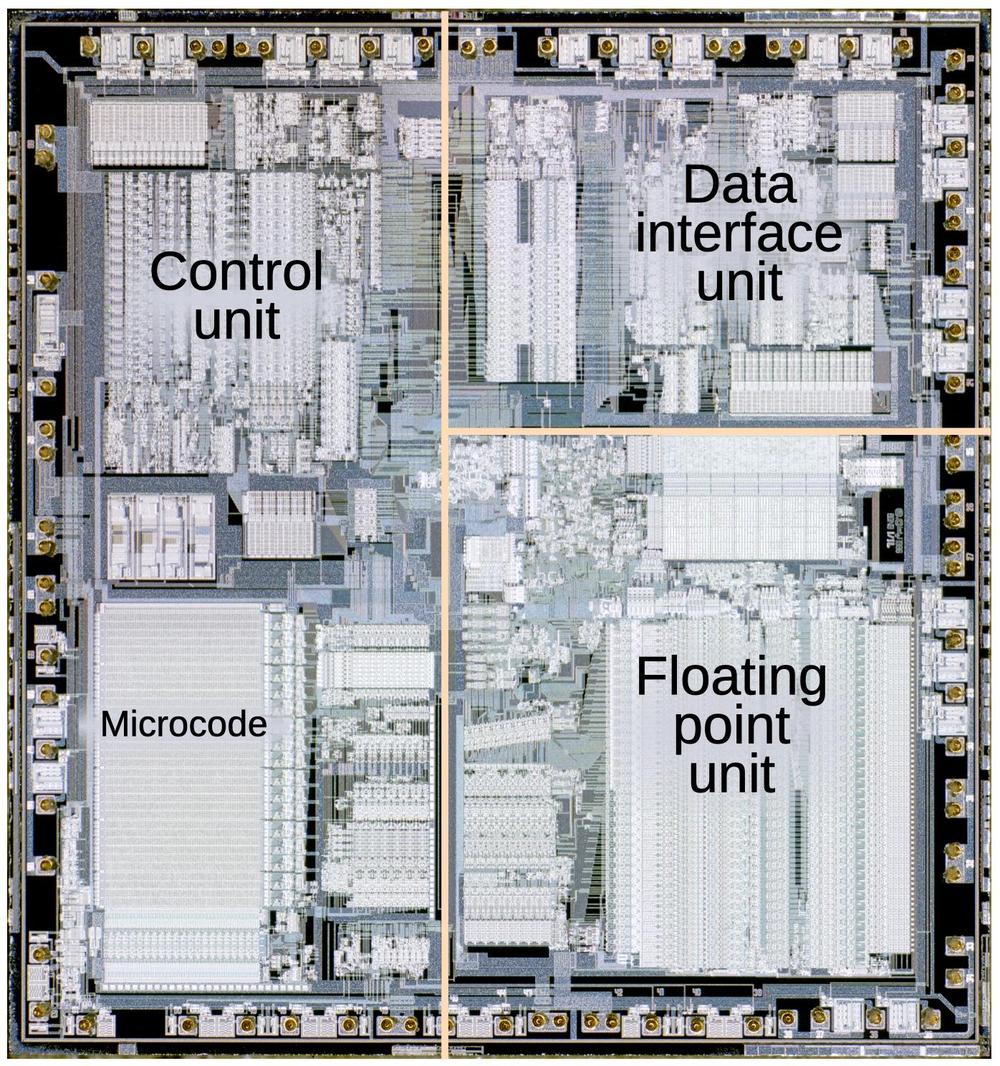

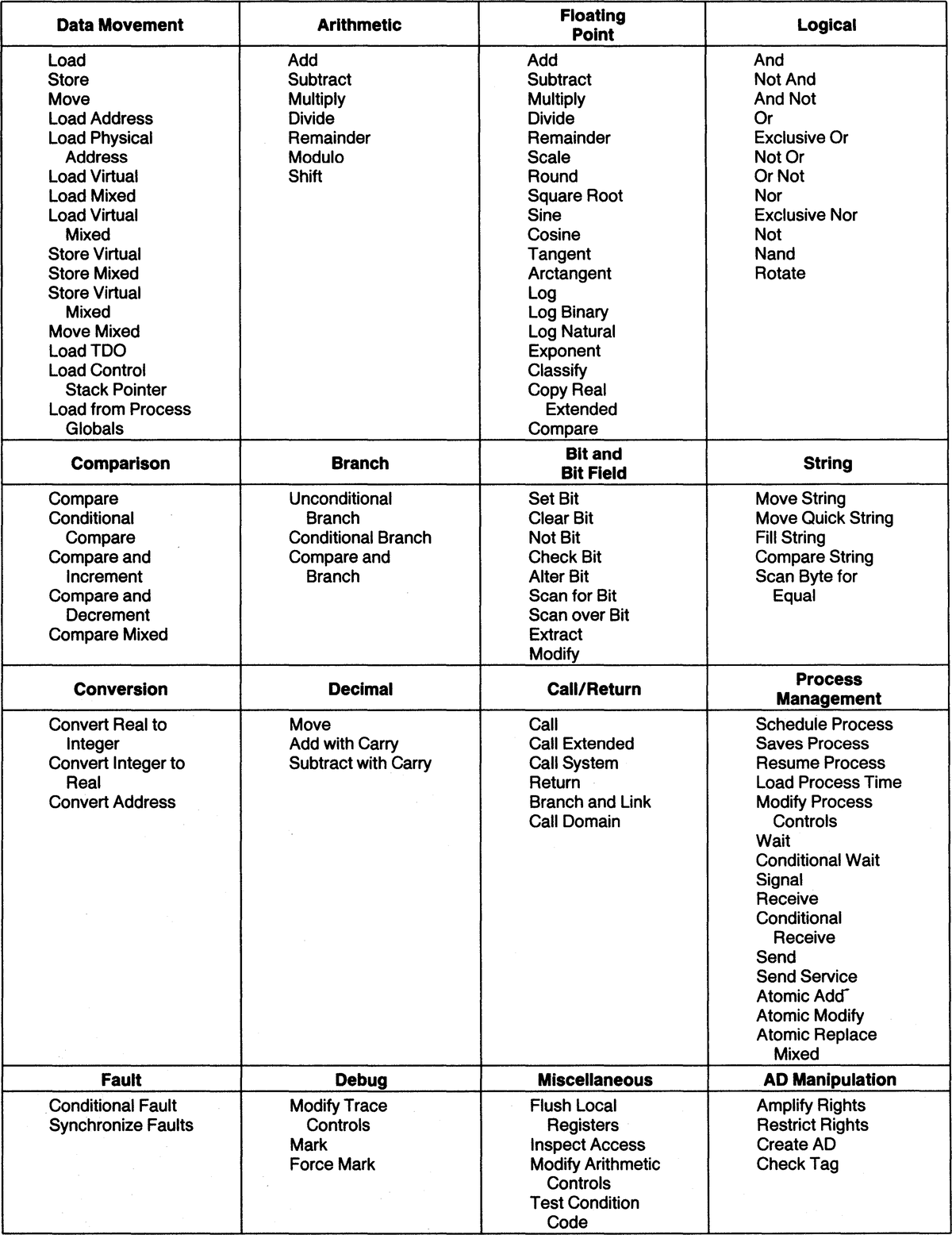

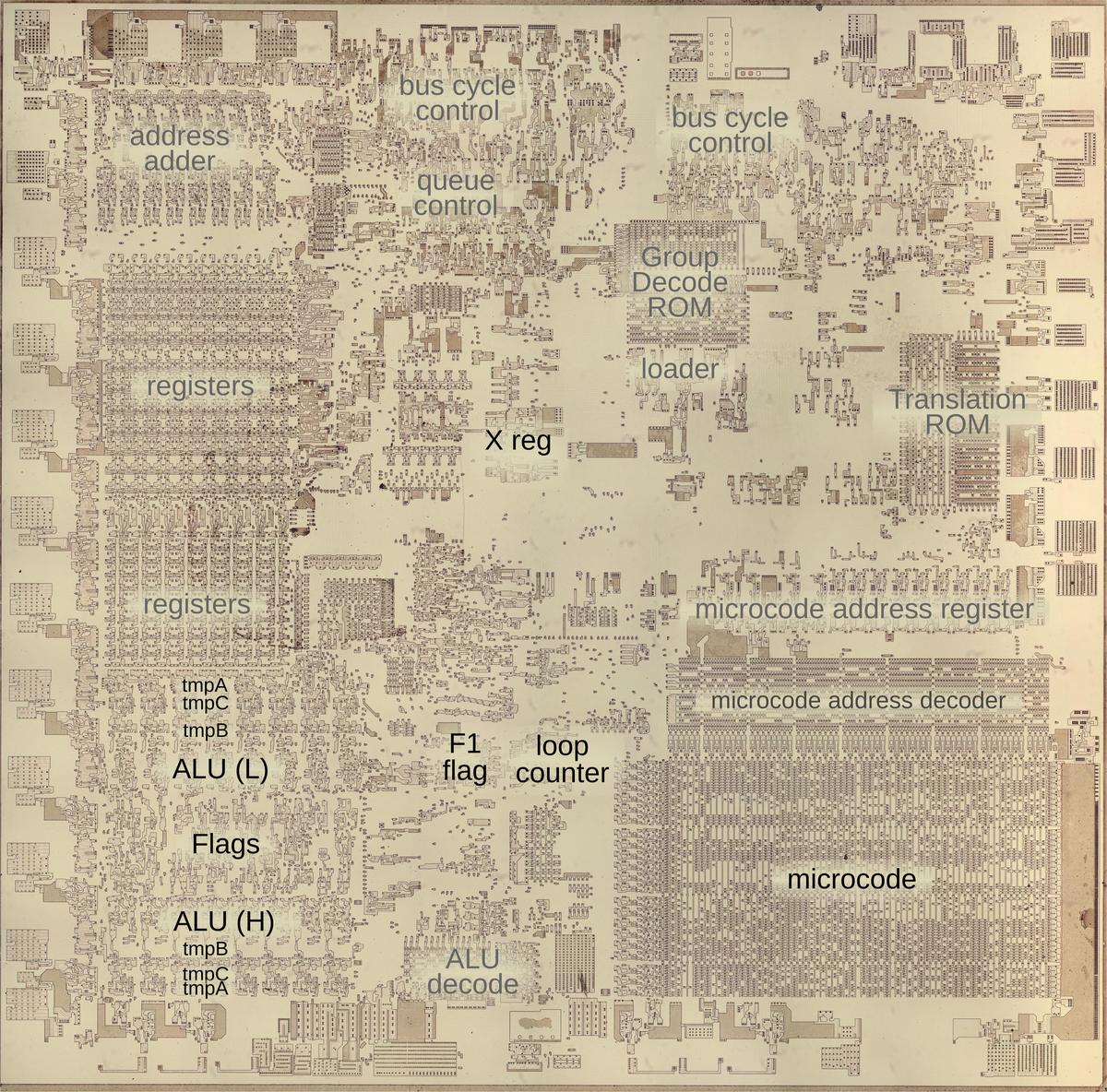

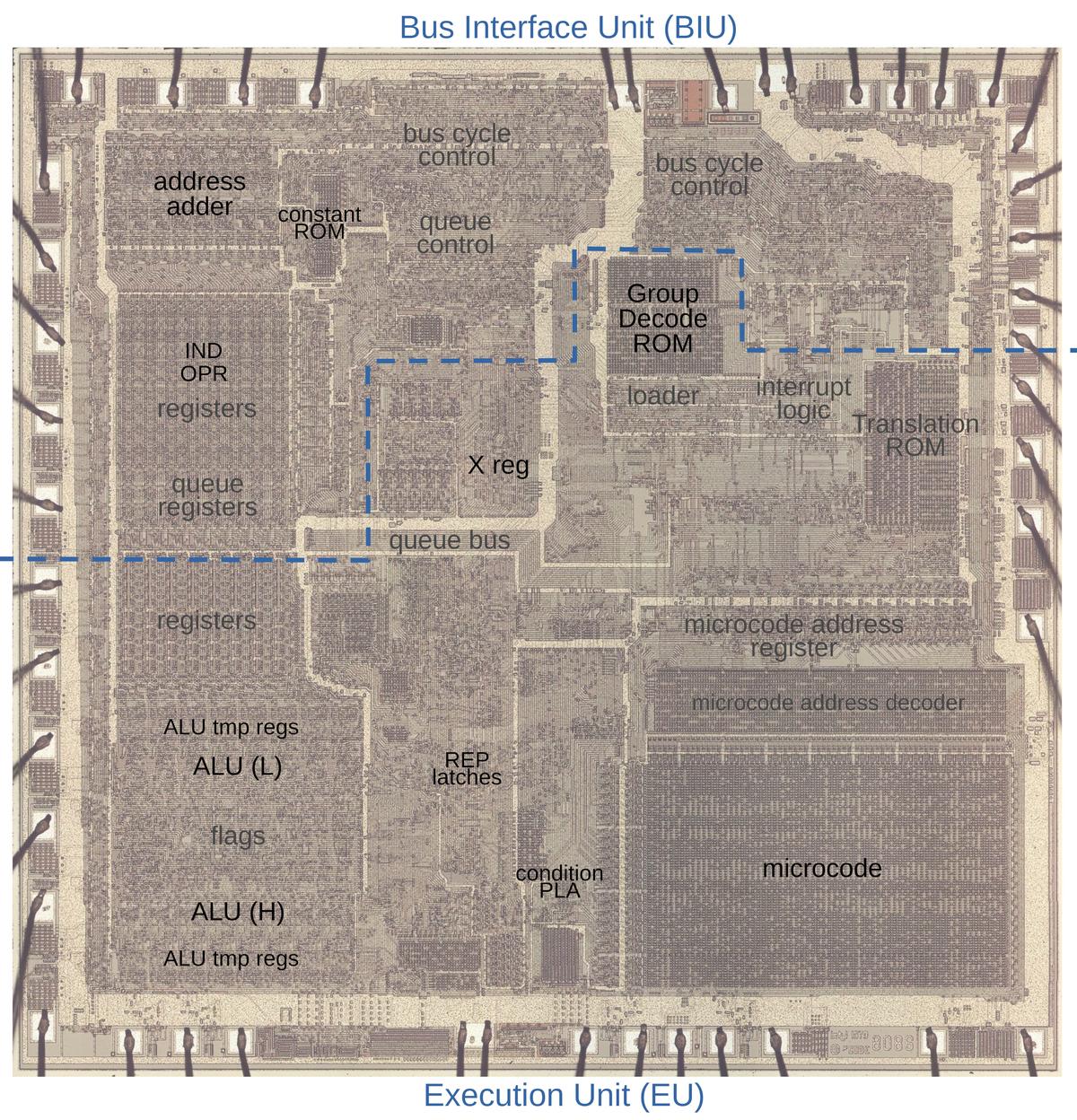

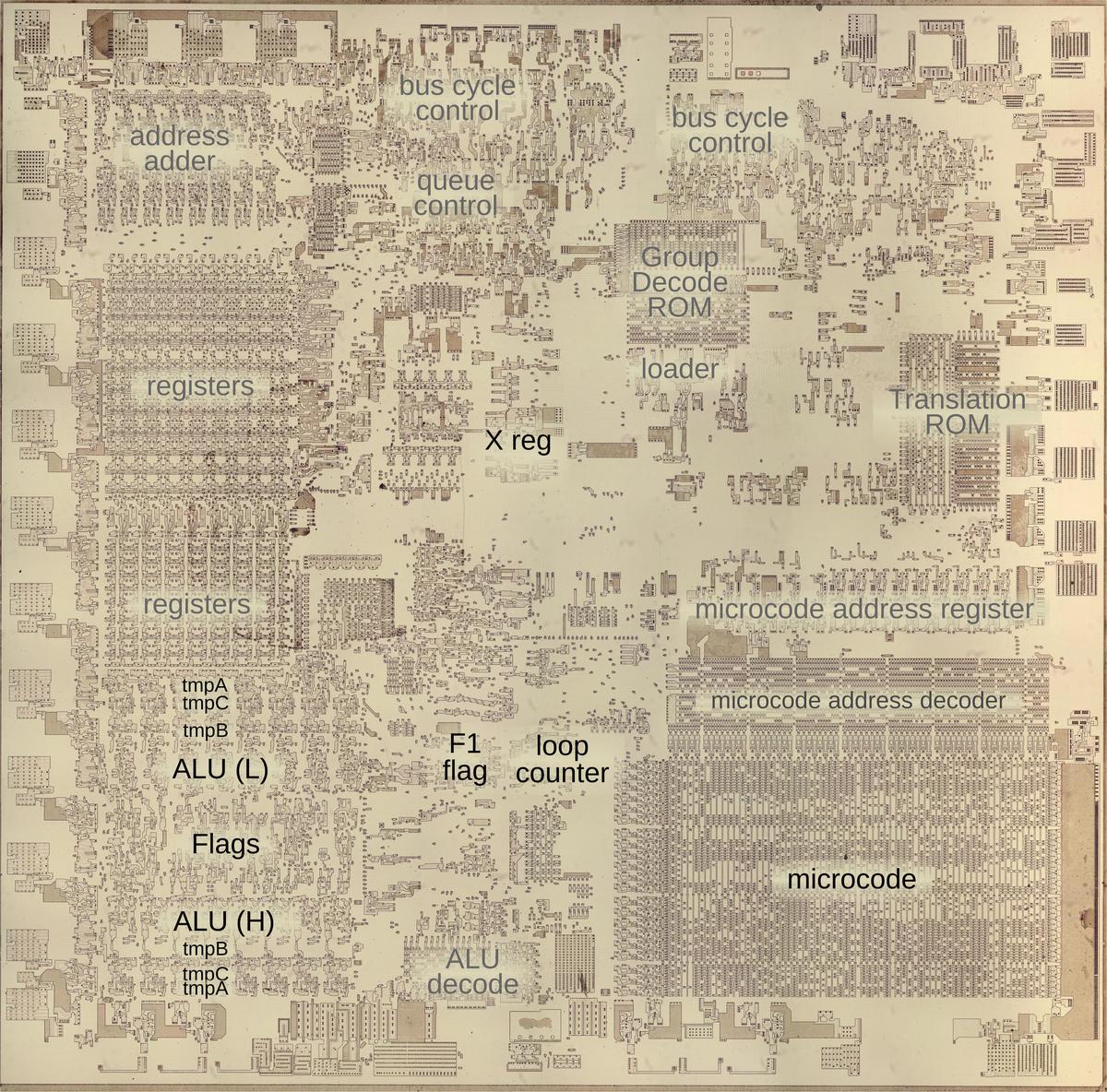

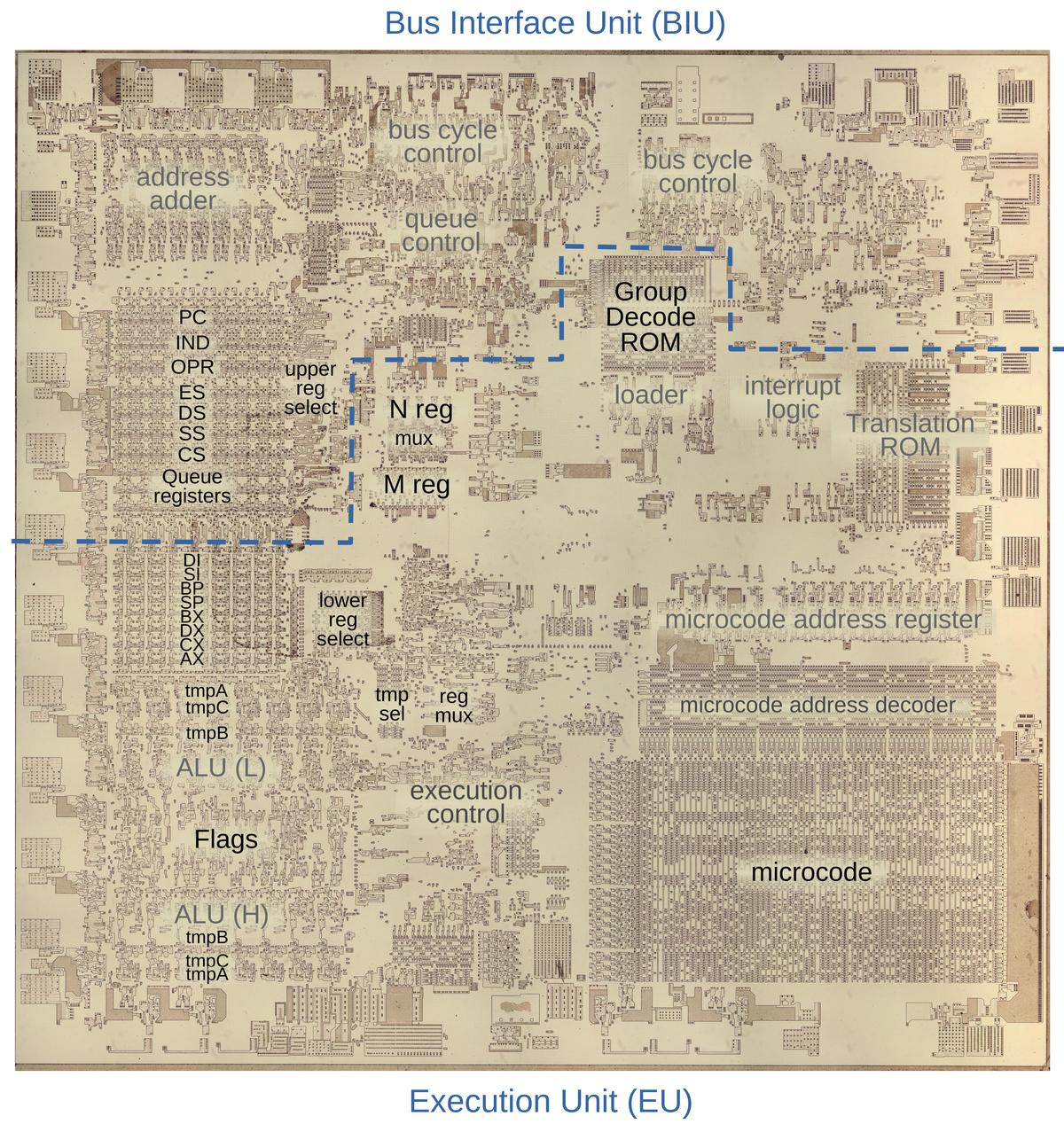

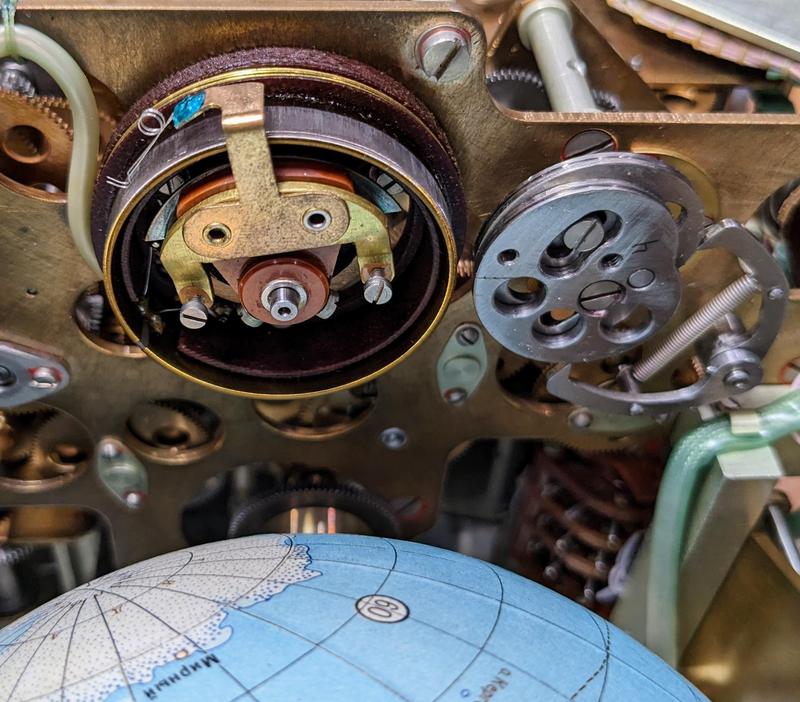

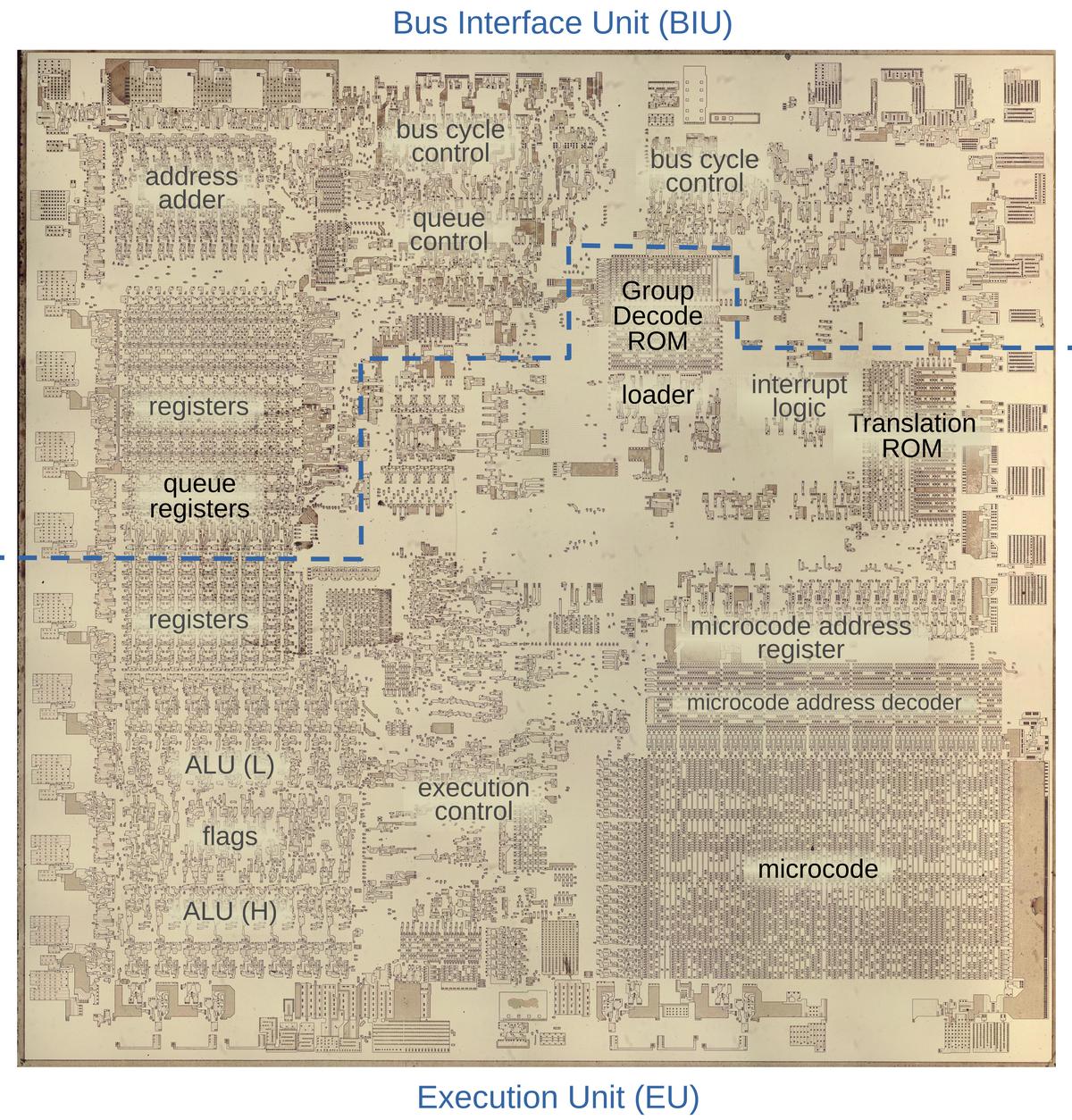

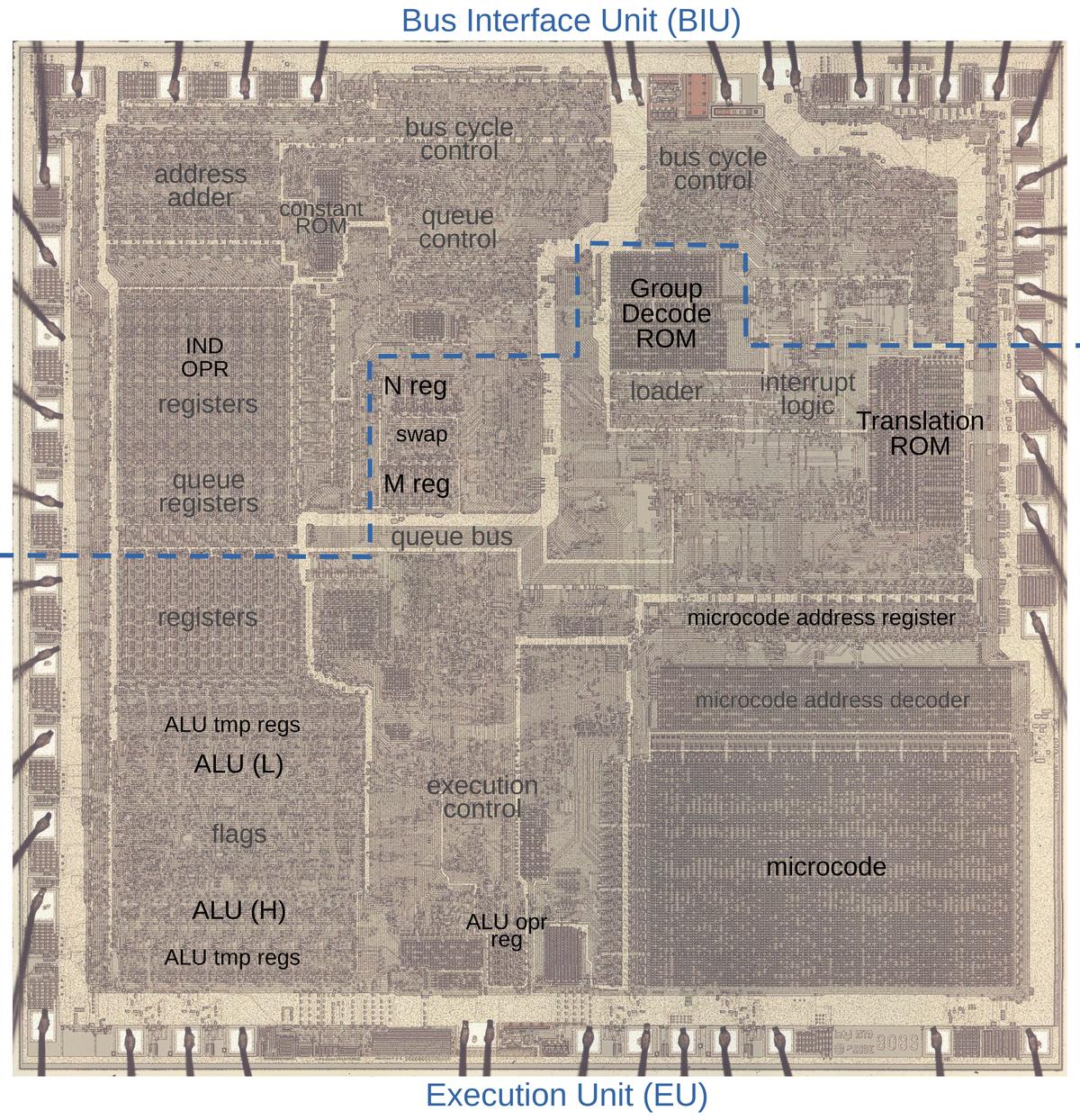

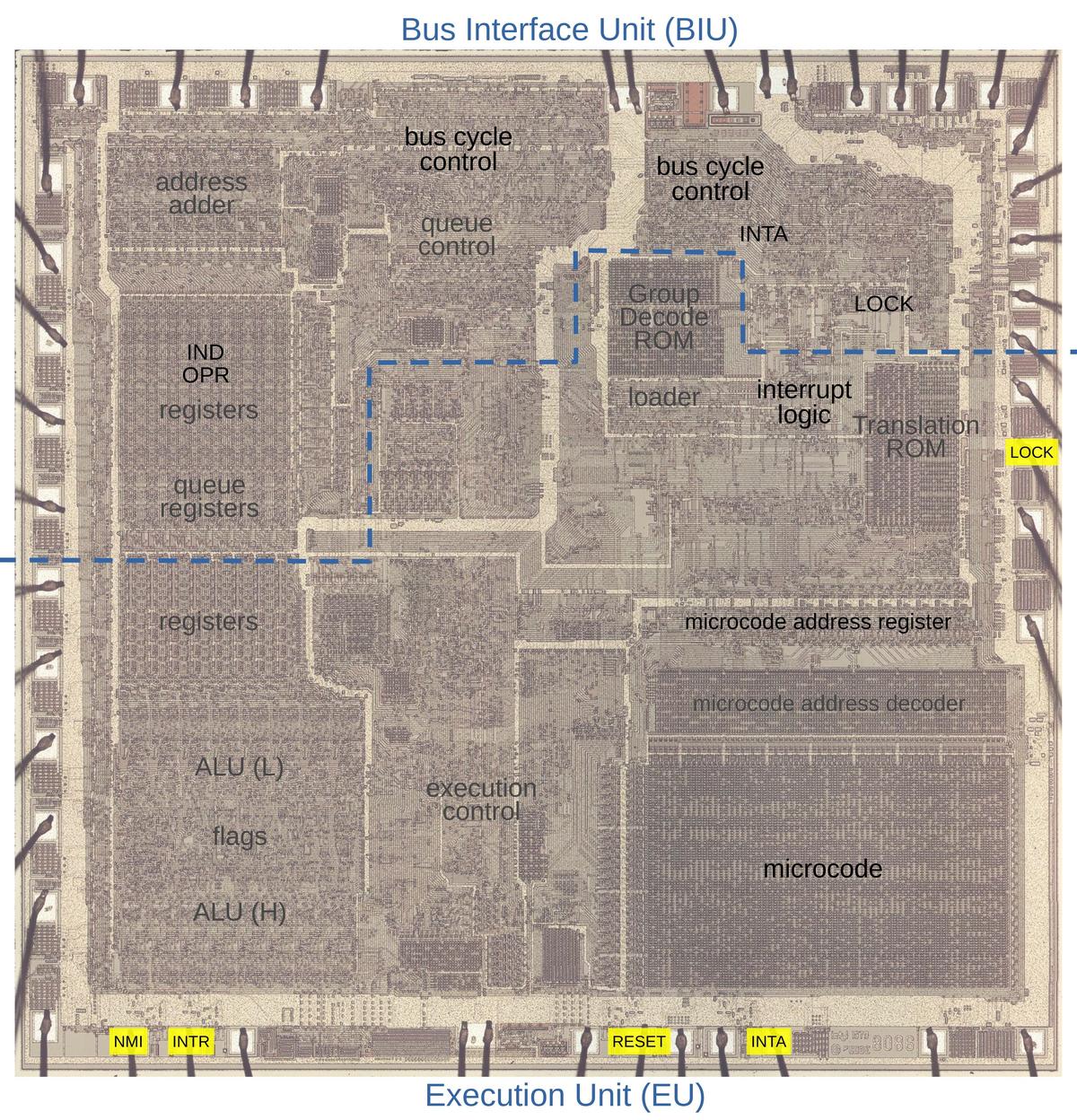

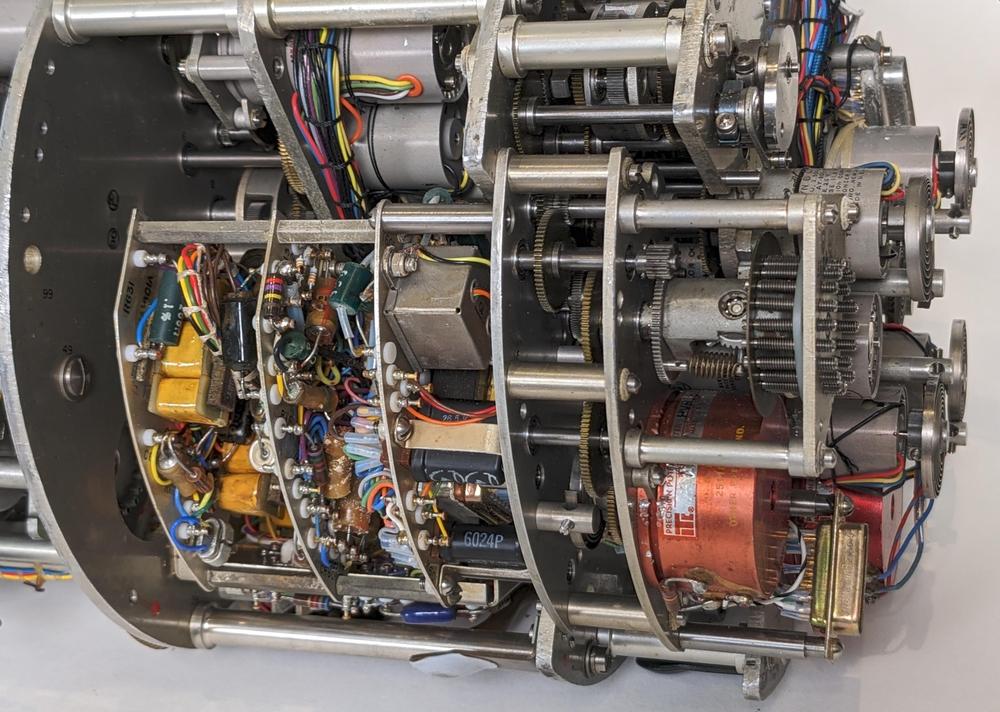

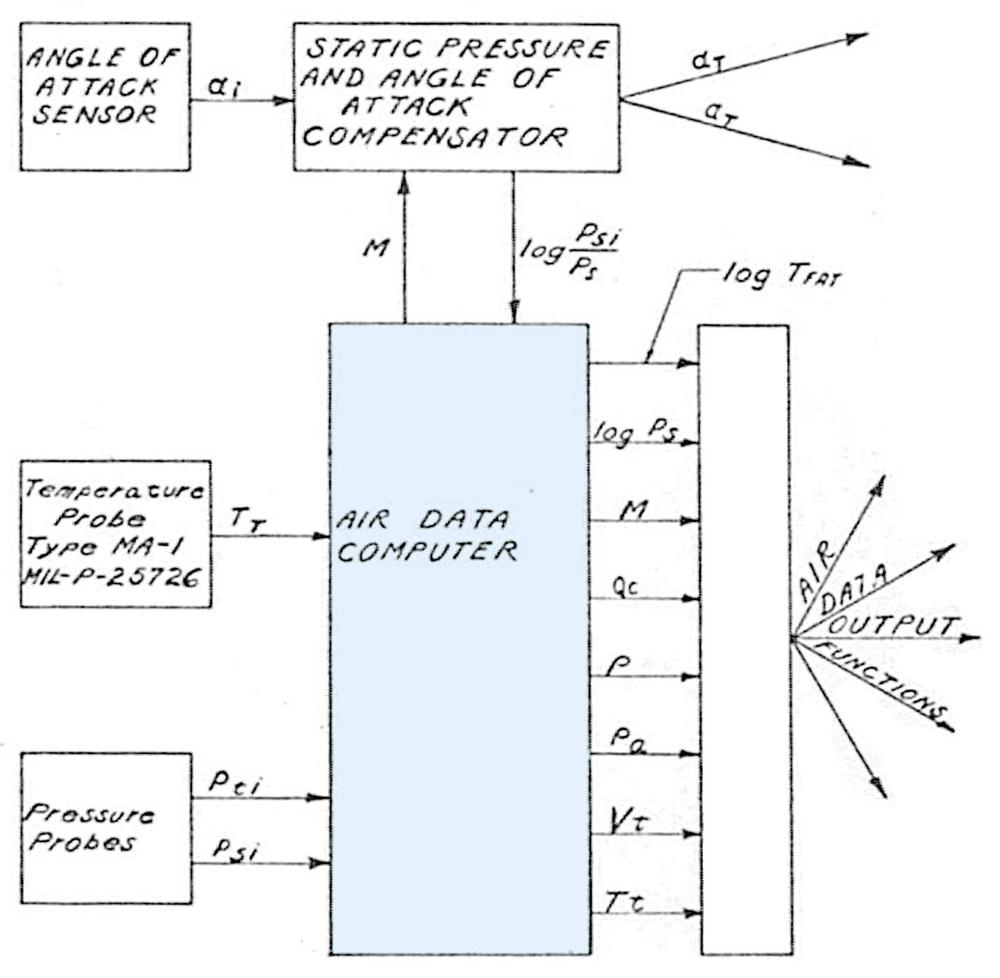

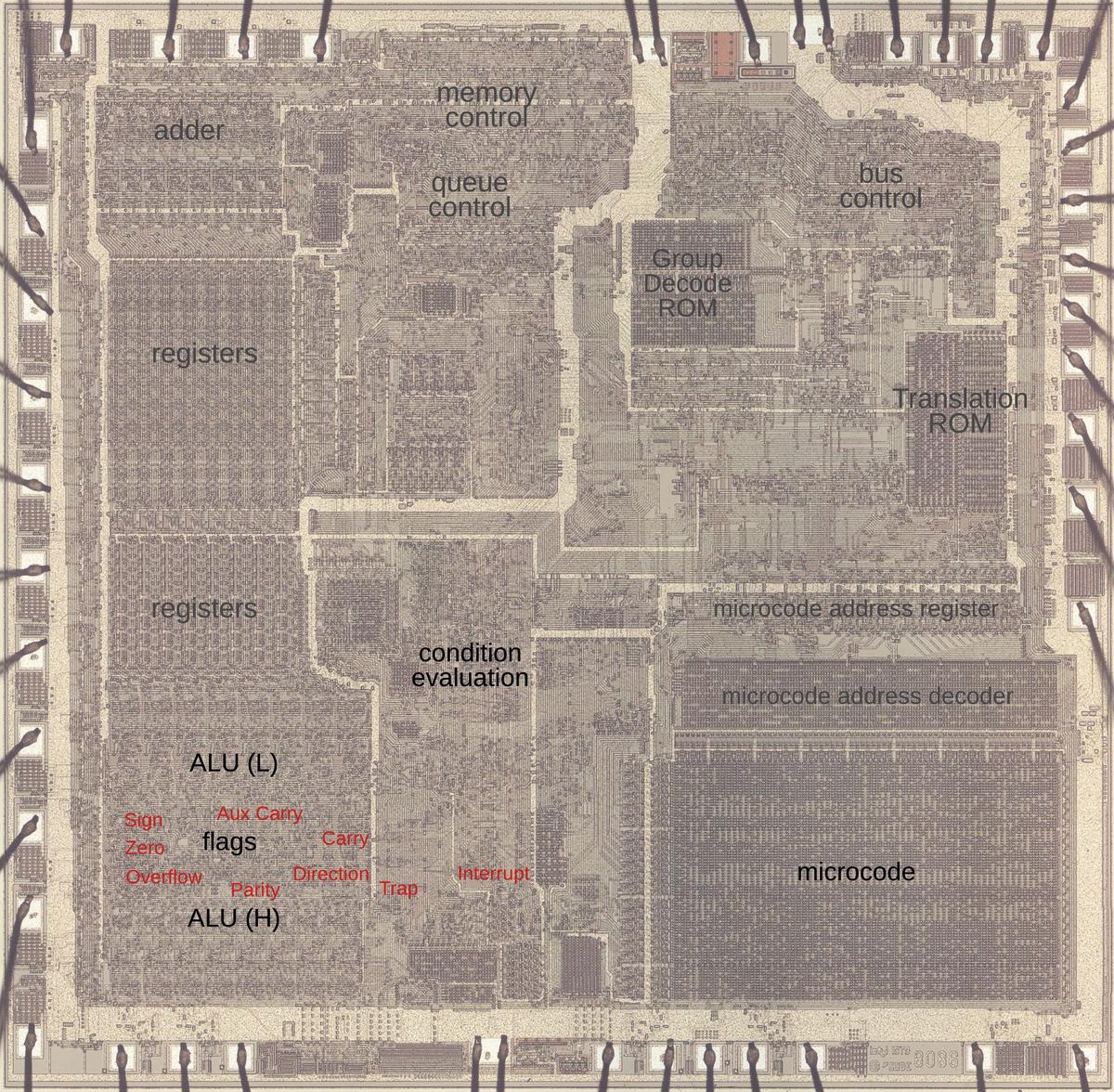

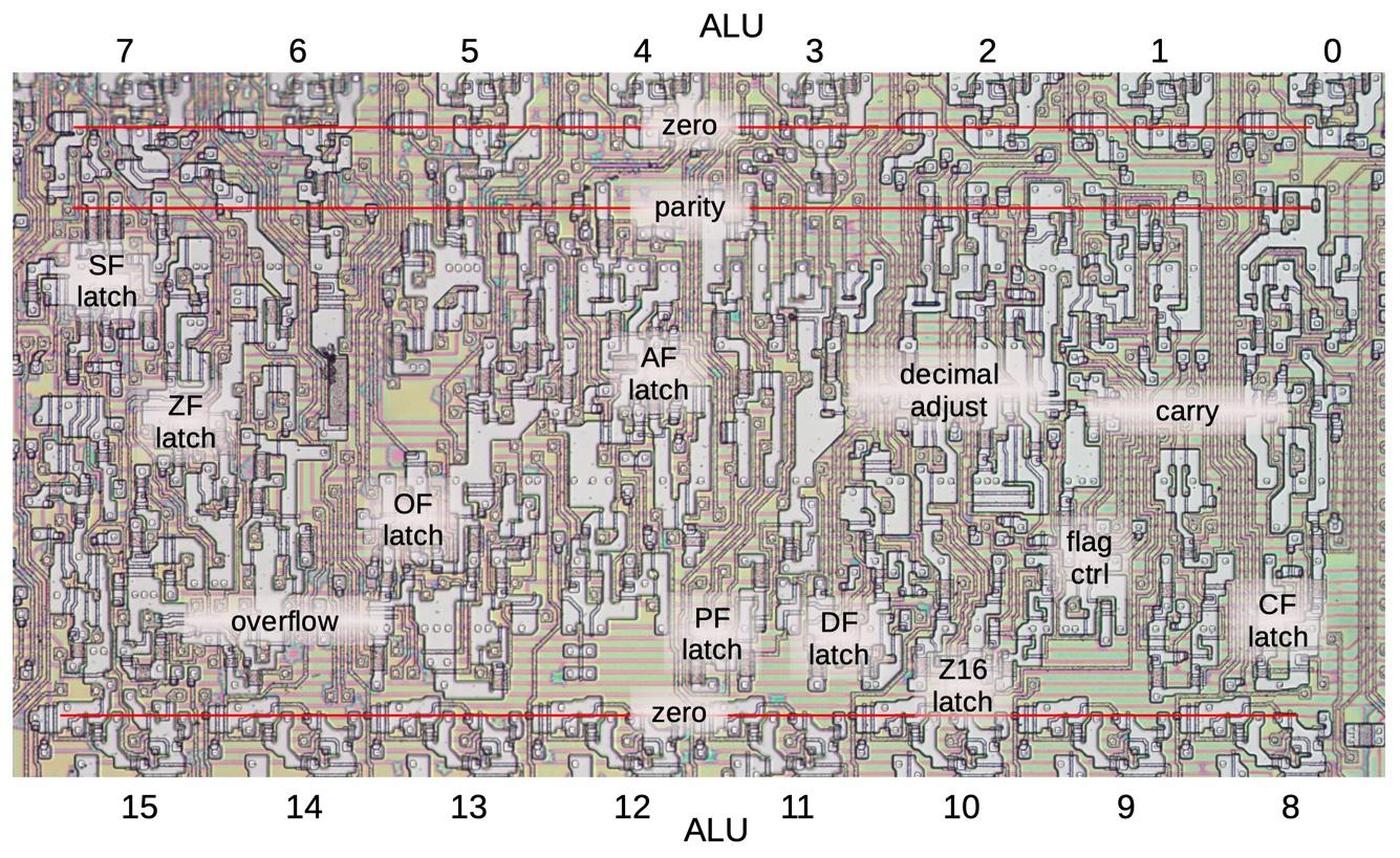

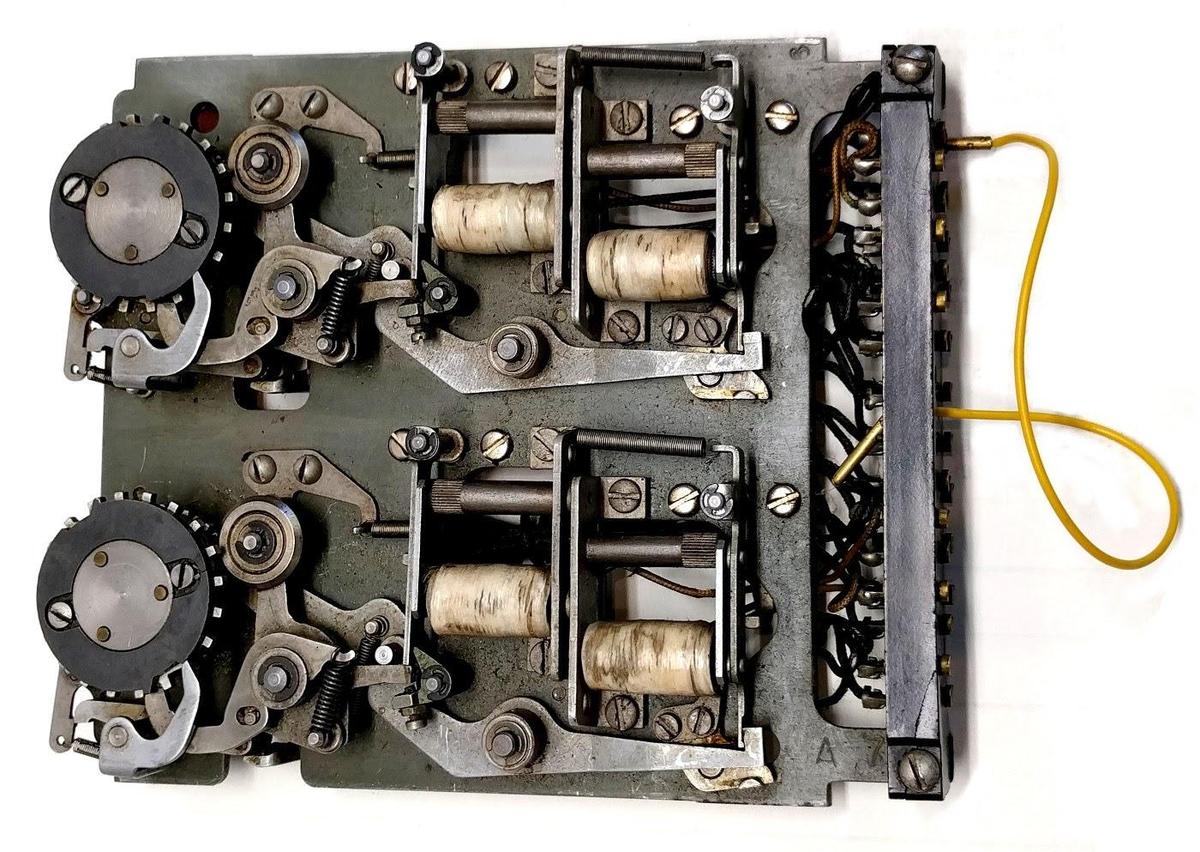

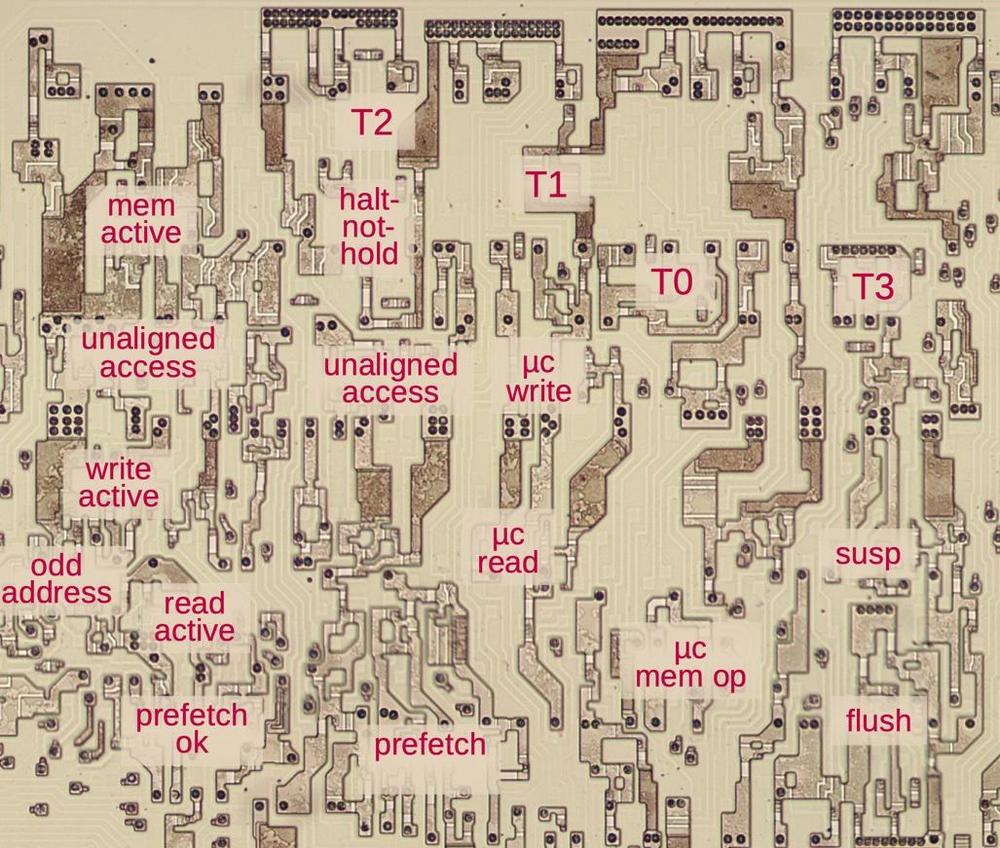

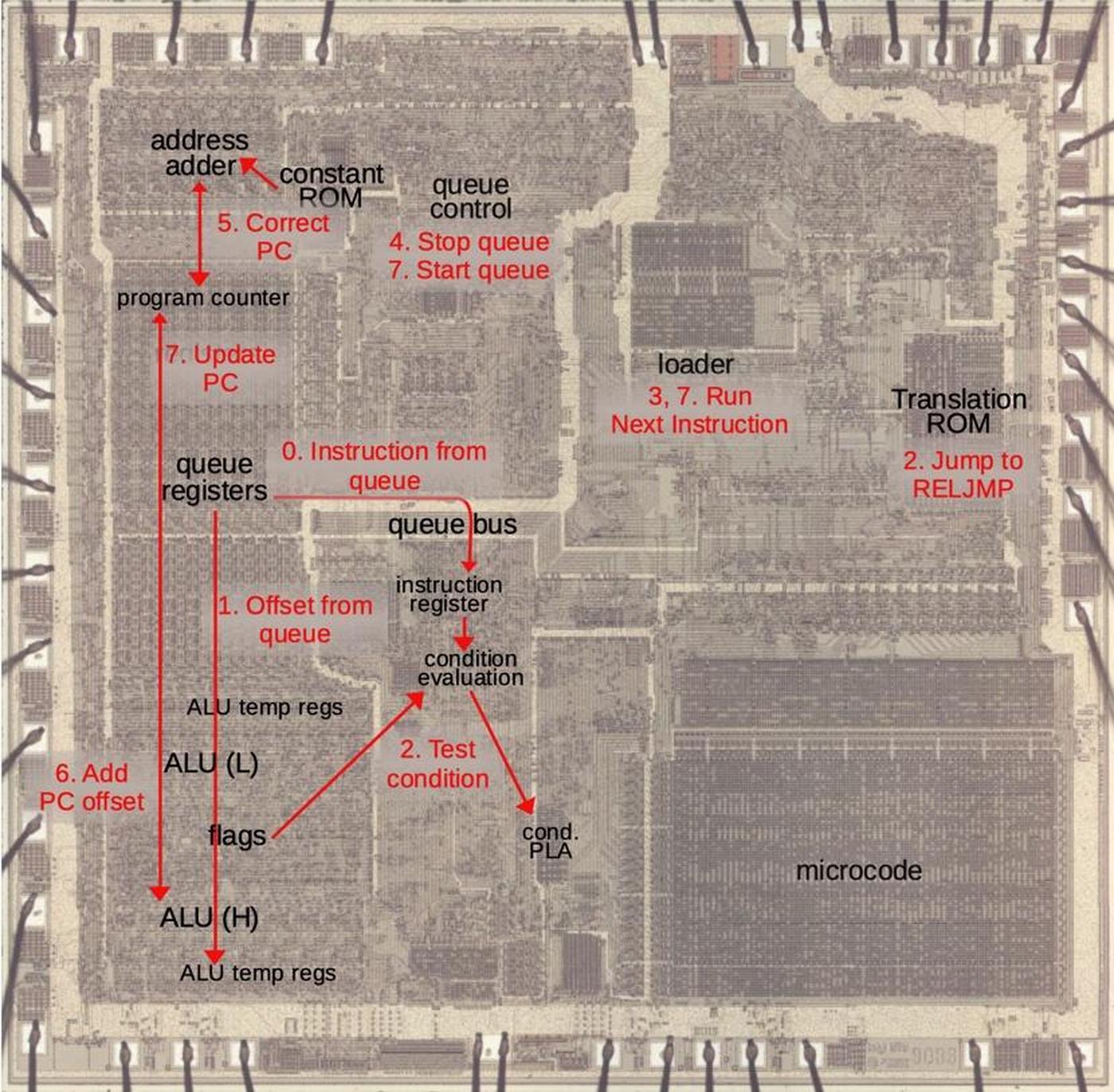

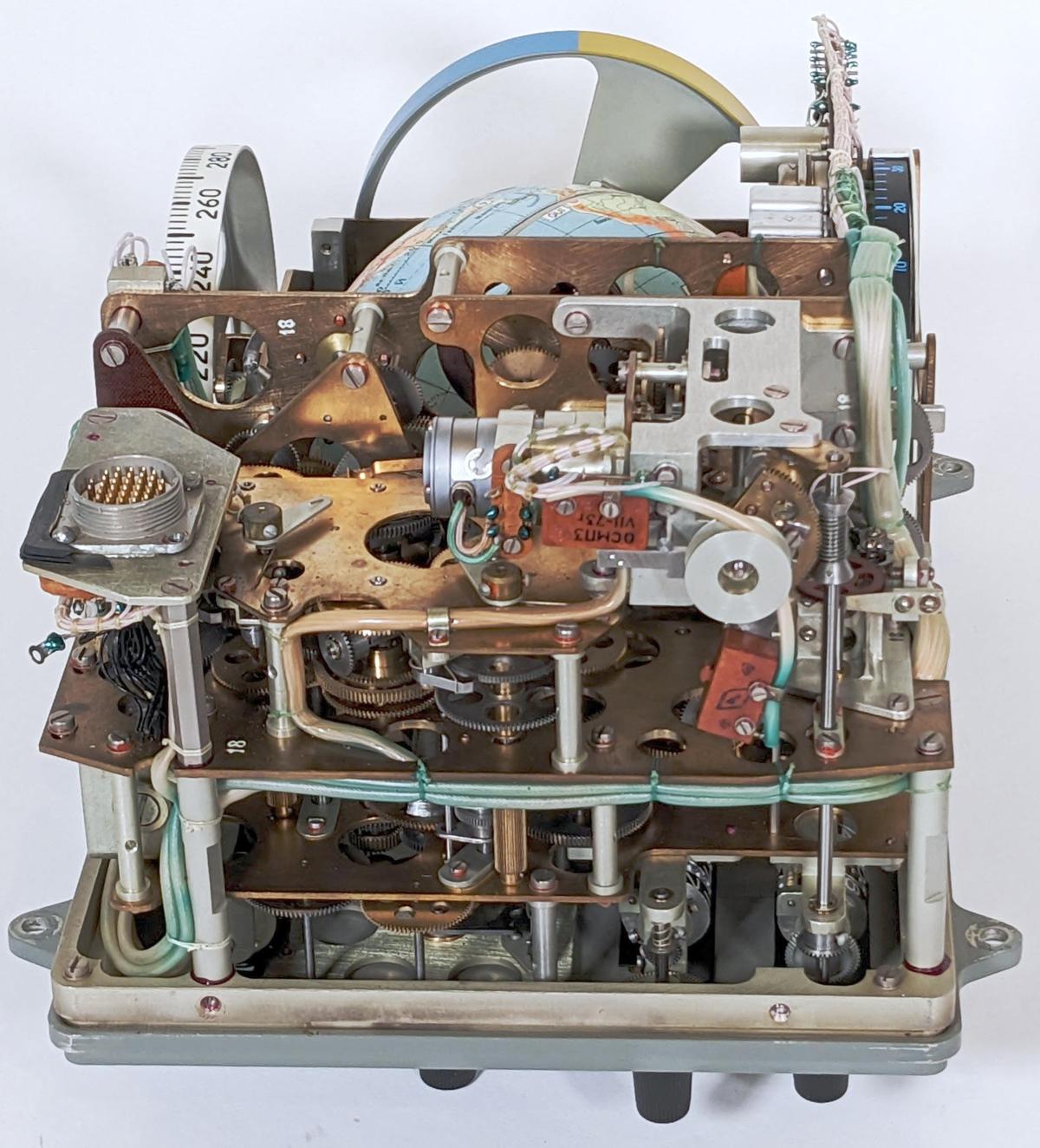

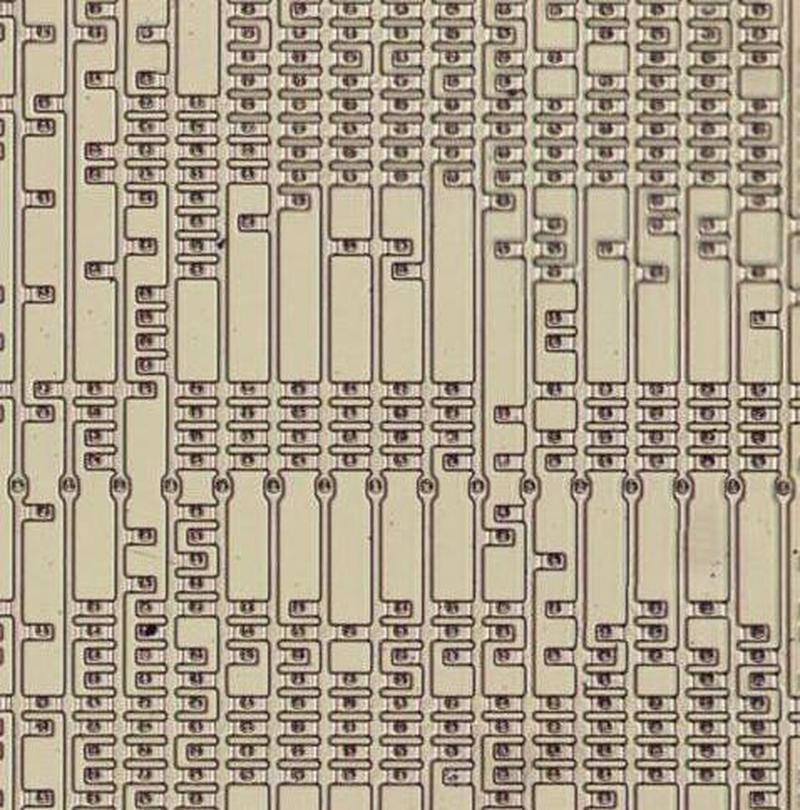

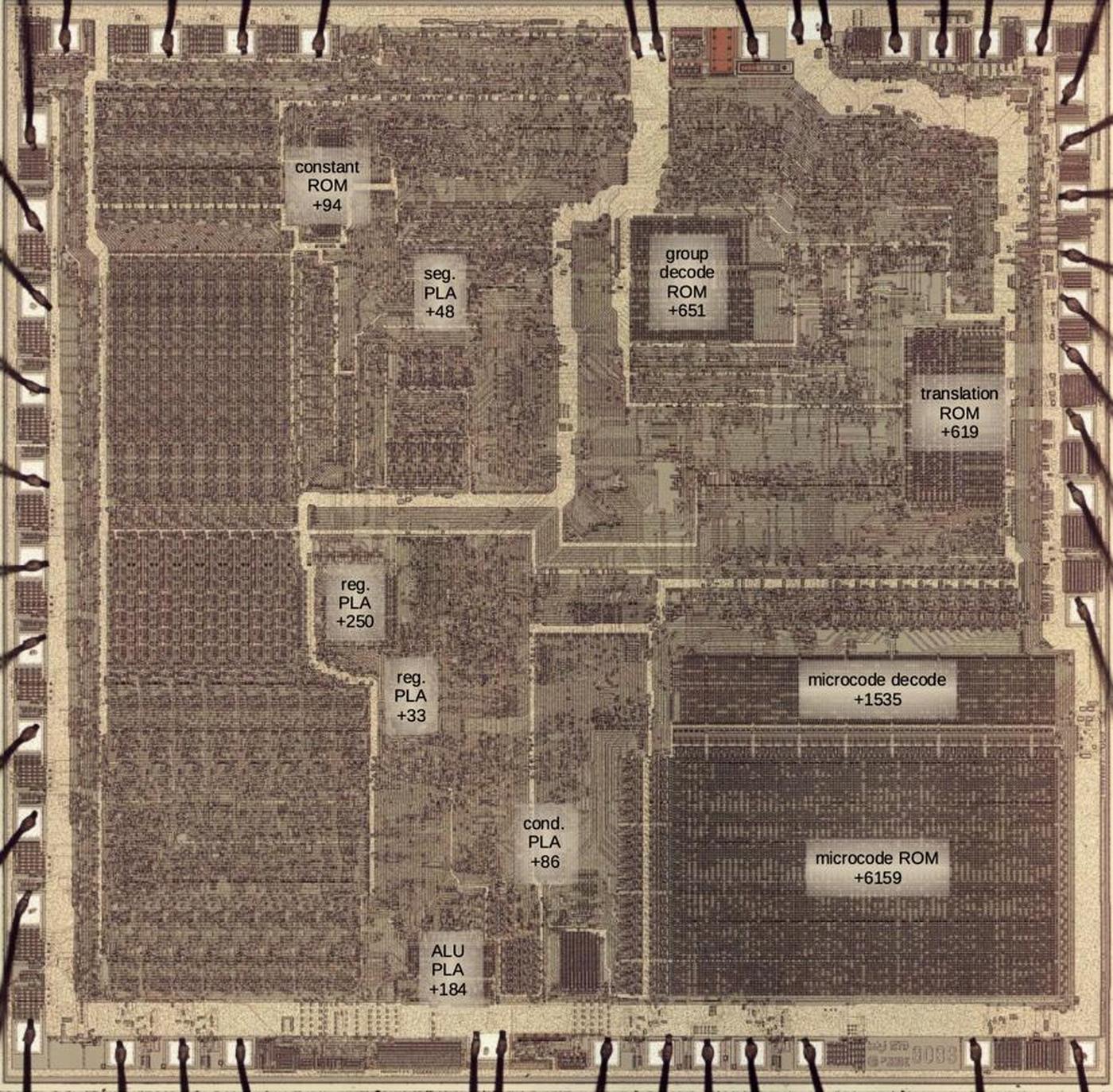

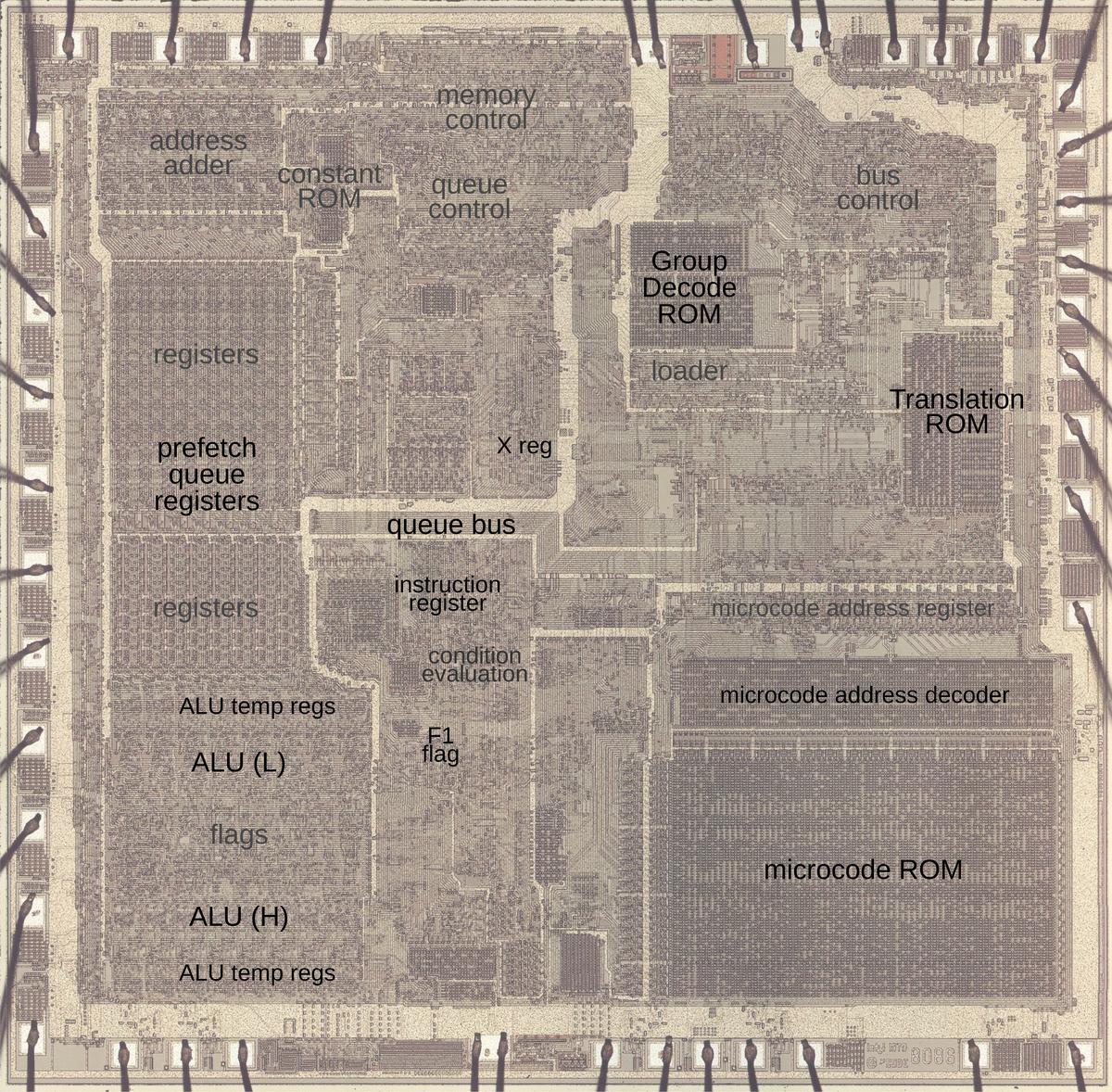

The photo below shows the 8086 die under a microscope, with the important functional blocks labeled. The metal layer is visible, while the underlying silicon and polysilicon wiring is mostly hidden. The microcode ROM and the microcode address decoder are in the lower right. The Group Decode ROM (upper center) is also important, as it performs the first step of instruction decoding.

https://static.righto.com/images/8086-ad-undoc/die-labeled.jpg">

Microcode and 8086 instruction decoding

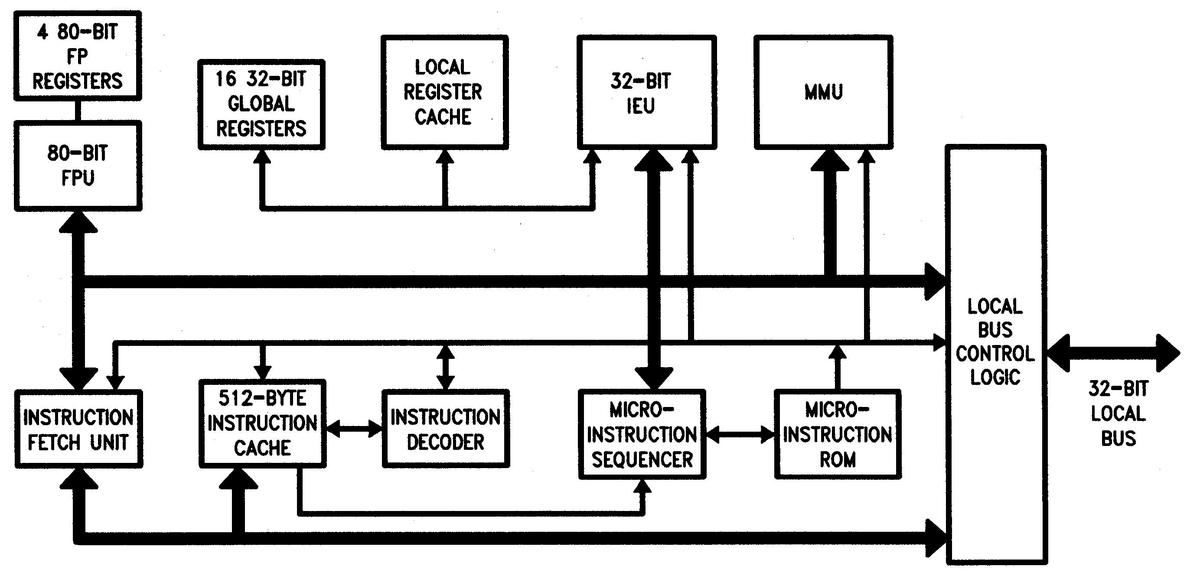

You might think that machine instructions are the basic steps that a computer performs. However, instructions usually require multiple steps inside the processor. One way of expressing these multiple steps is through microcode, a technique dating back to 1951. To execute a machine instruction, the computer internally executes several simpler micro-instructions, specified by the microcode. In other words, microcode forms nother layer between the machine instructions and the hardware. The main advantage of microcode is that it turns the processor's control logic into a programming task instead of a difficult logic design task.

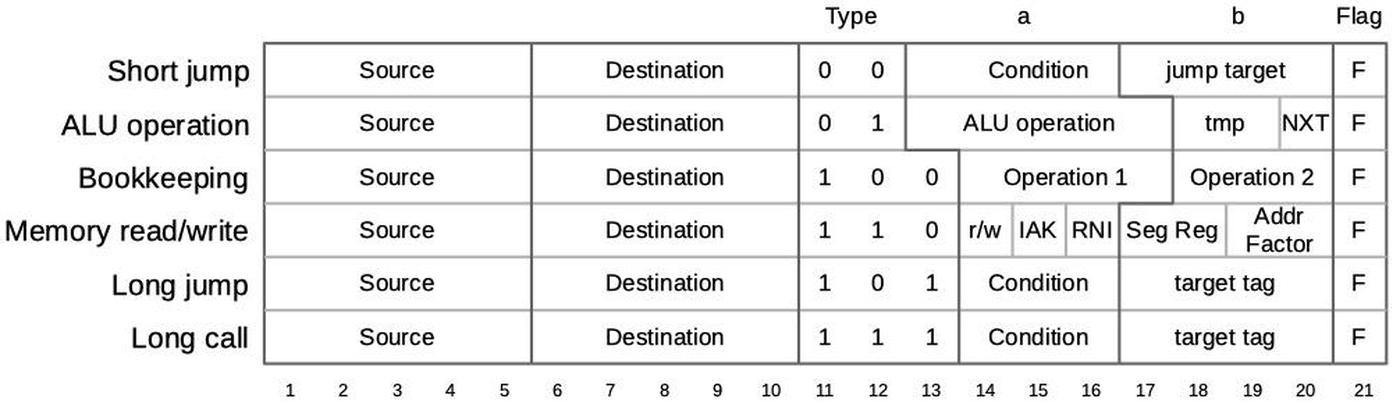

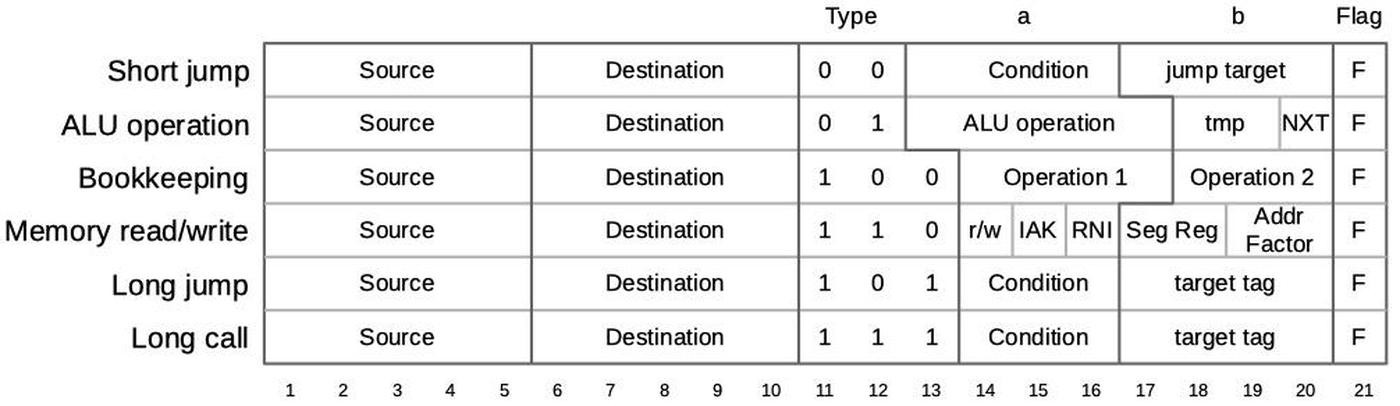

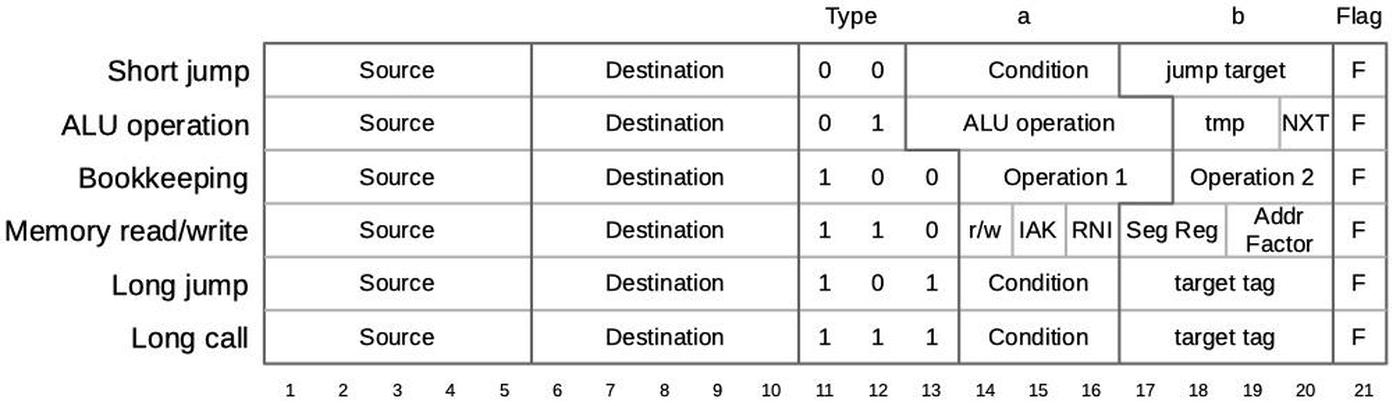

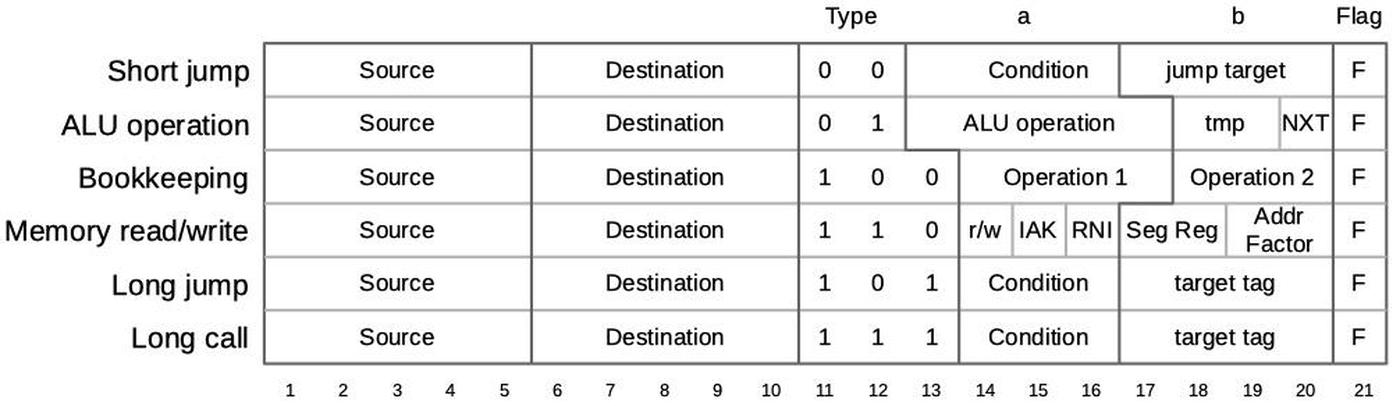

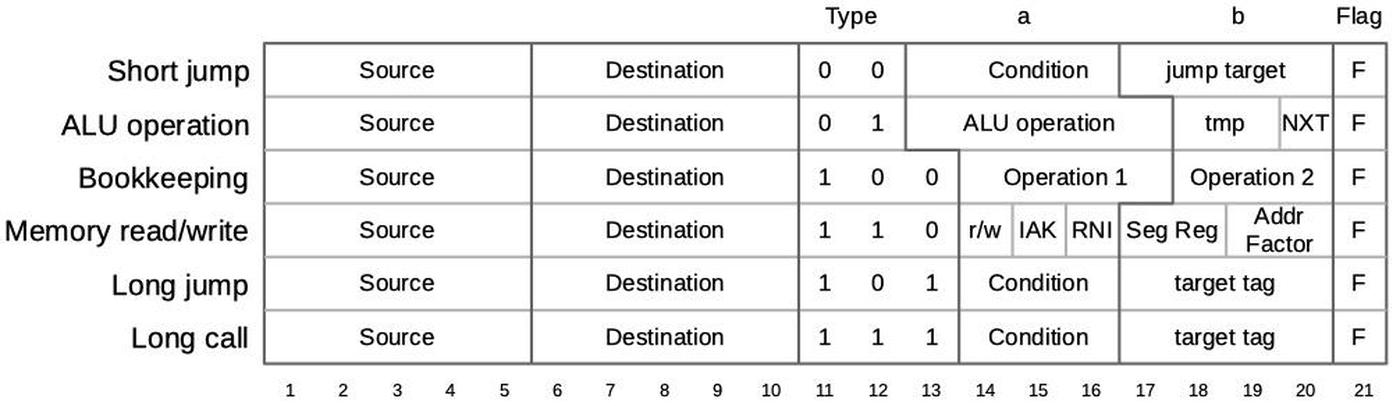

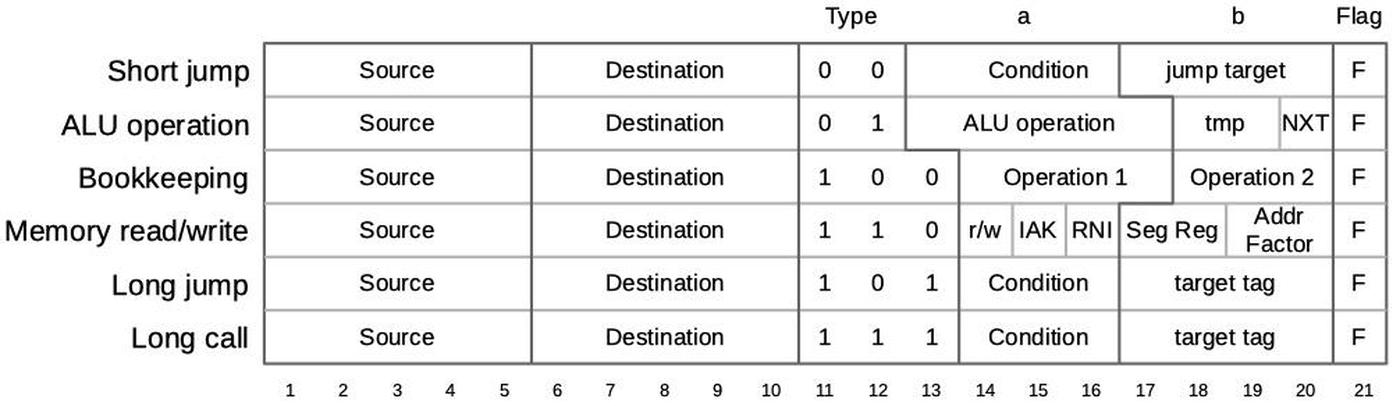

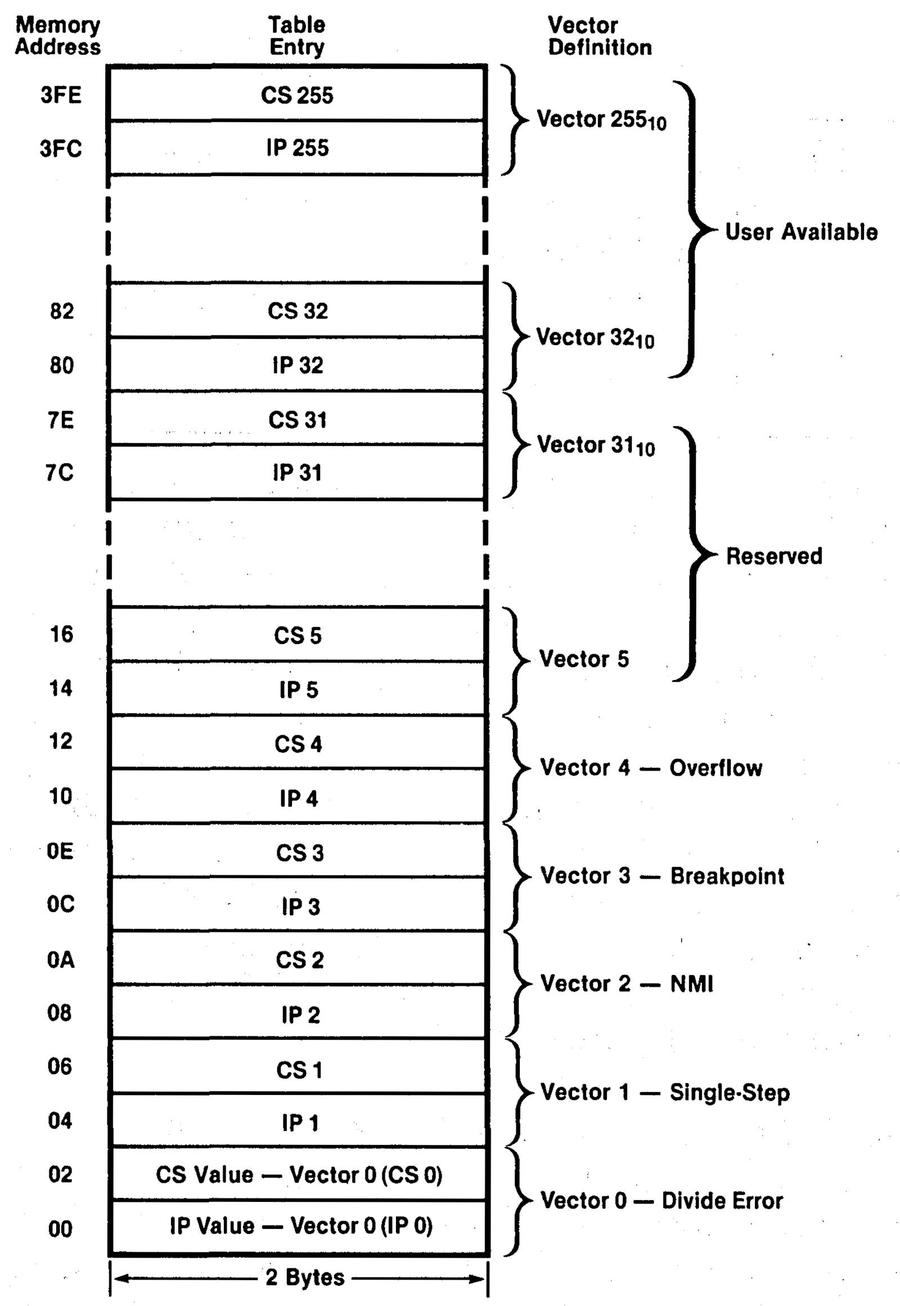

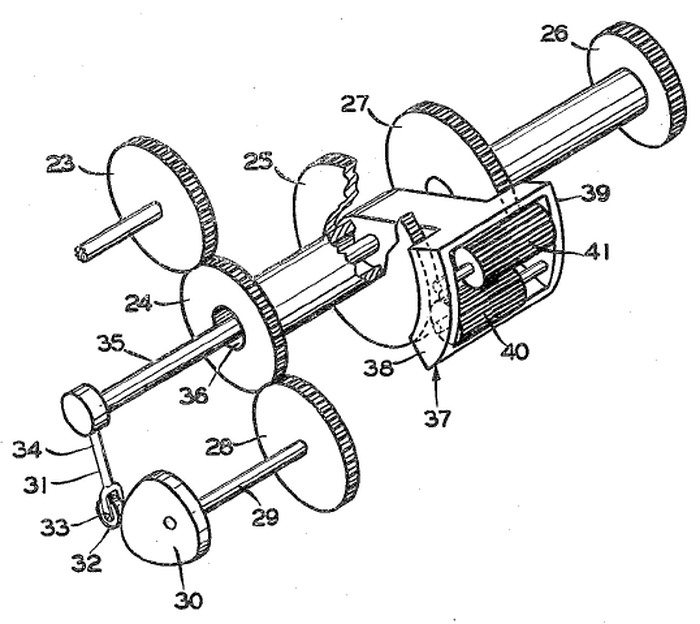

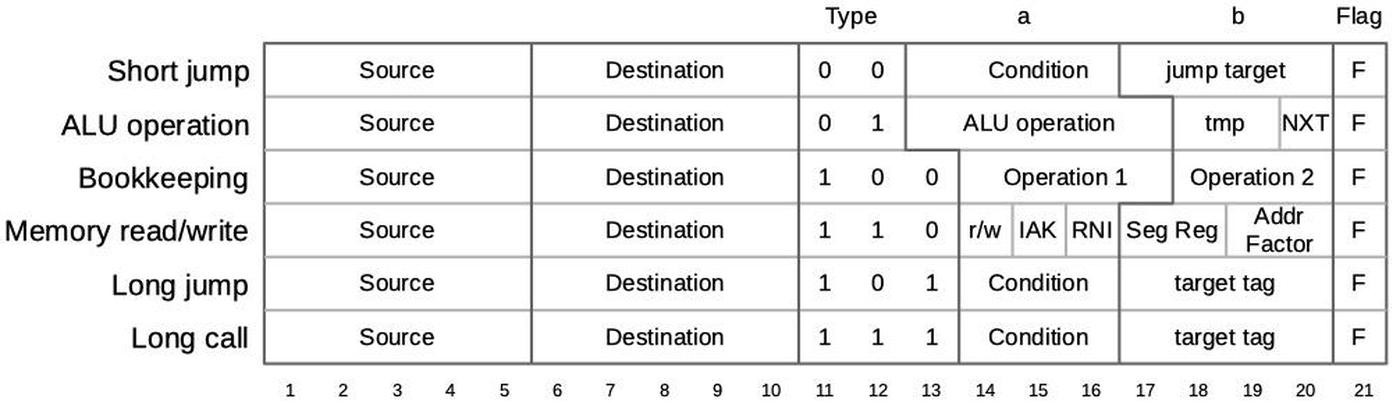

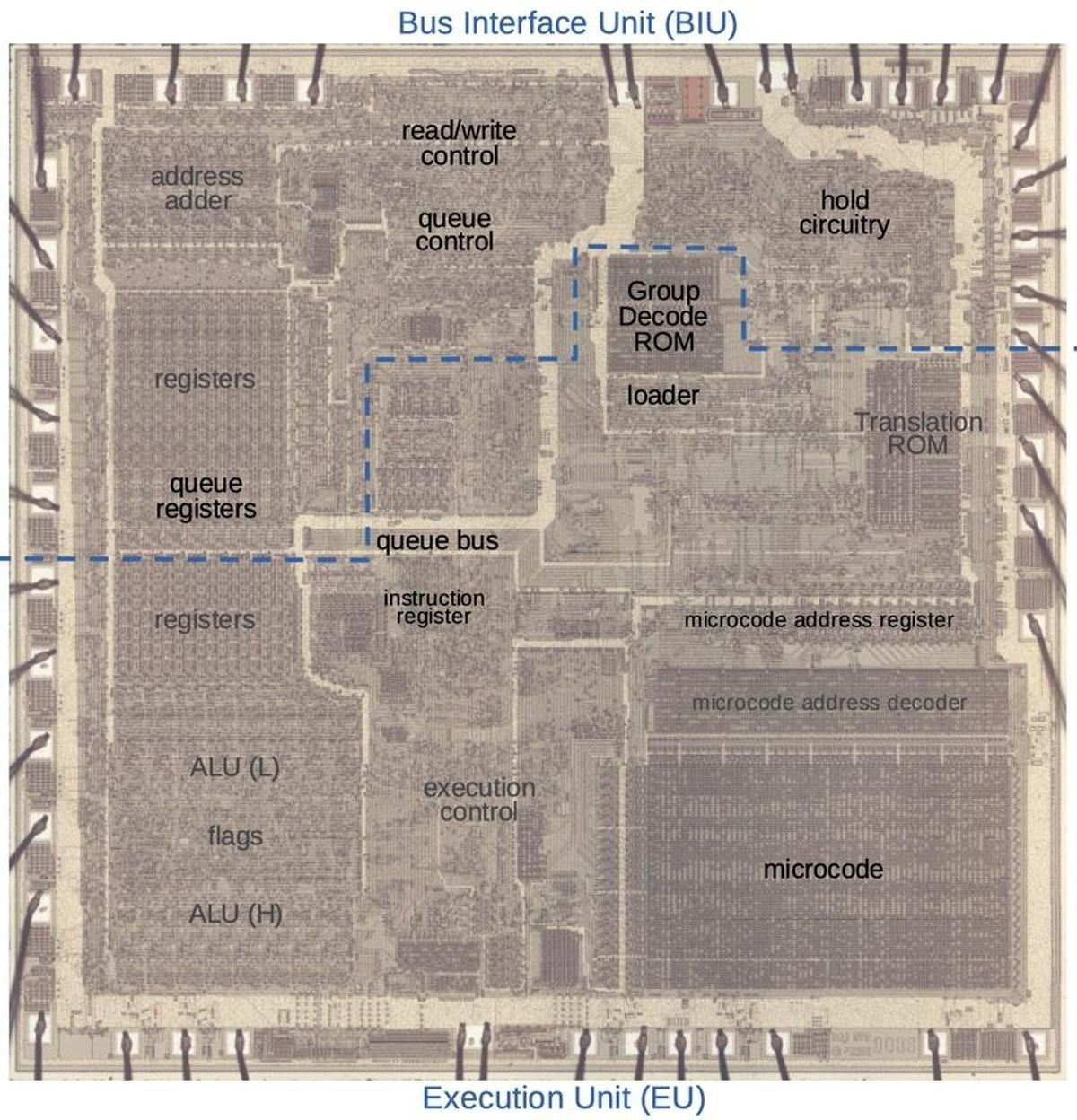

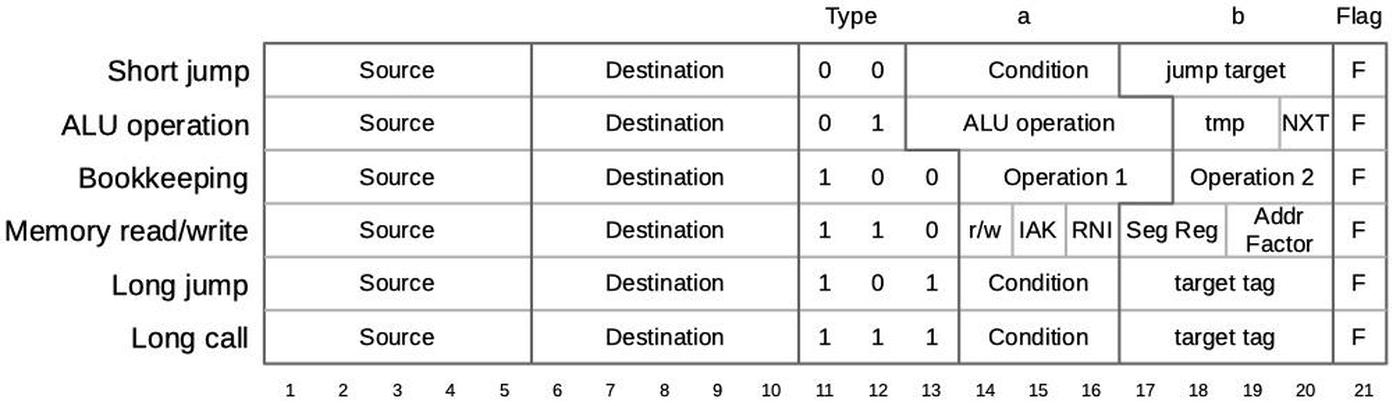

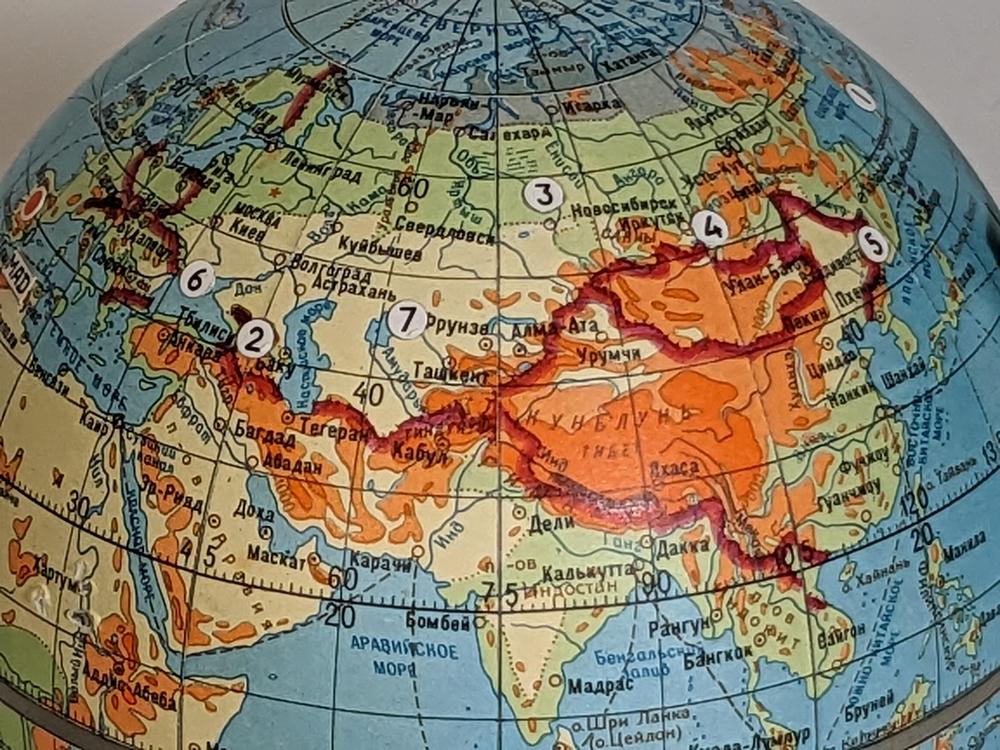

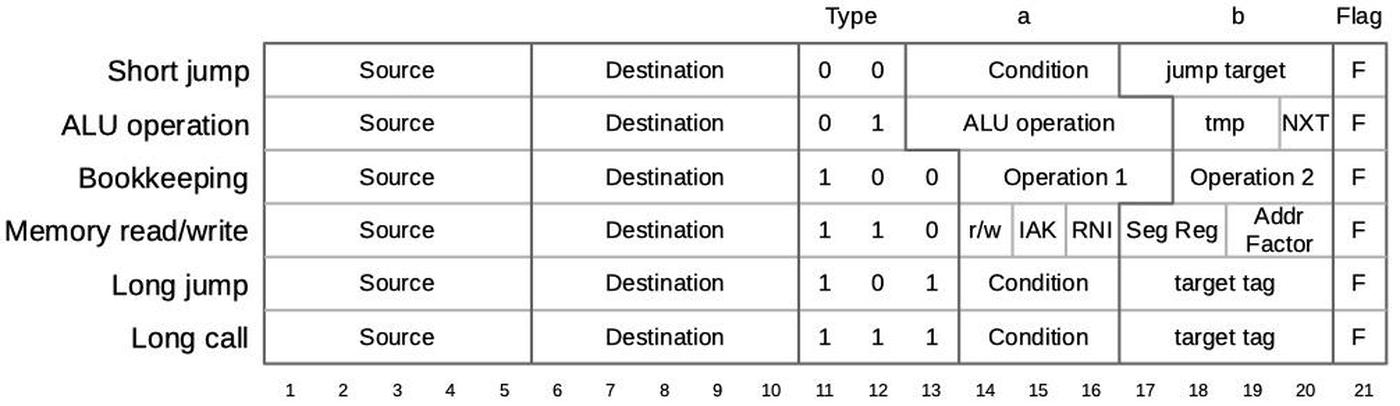

The 8086's https://www.righto.com/2022/11/how-8086-processors-microcode-engine.html">microcode ROM holds 512 micro-instructions, each 21 bits wide. Each micro-instruction performs two actions in parallel. First is a move between a source and a destination, typically registers. Second is an operation that can range from an arithmetic (ALU) operation to a memory access. The diagram below shows the structure of a 21-bit micro-instruction, divided into six types.

https://static.righto.com/images/8086-ad-undoc/microcode-format.jpg">

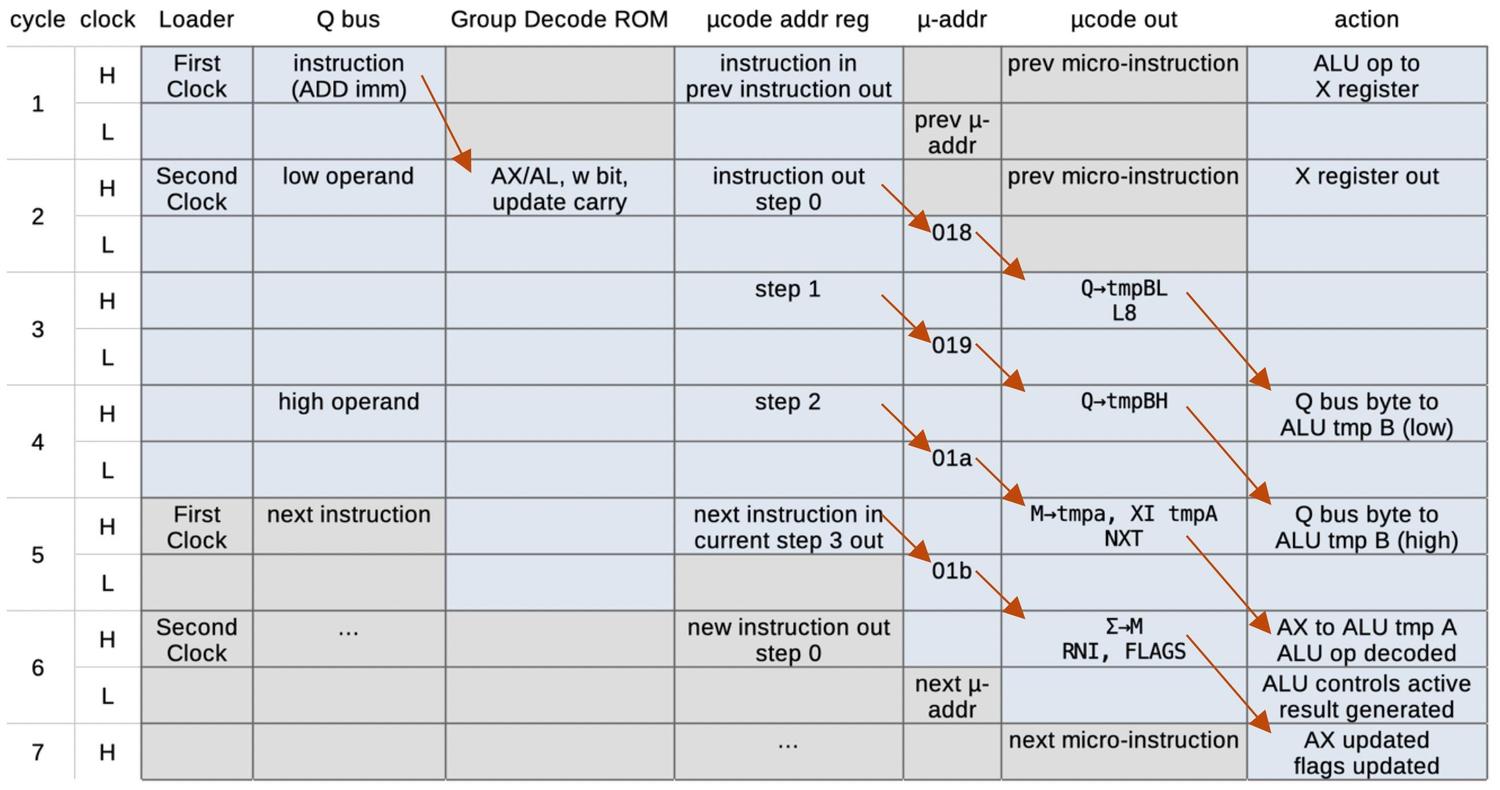

When executing a machine instruction, the 8086 performs a decoding step.

Although the 8086 is a 16-bit processor, its instructions are based on bytes. In most cases, the first byte specifies the

opcode, which may be followed by additional instruction bytes.

In other cases, the byte is a "prefix" byte, which changes the behavior of the following instruction.

The first byte is analyzed

by something called the https://www.righto.com/2023/05/8086-processor-group-decode-rom.html">Group Decode ROM.

This circuit categorizes the first byte of the instruction into about 35 categories that control how the instruction is

decoded and executed.

One category is "1-byte logic"; this indicates a one-byte instruction or prefix that is simple and implemented by logic circuitry in the 8086.

For instructions in this category, microcode is not involved while

the remaining instructions are implemented in microcode.

Many of these instructions are in the "two-byte ROM" category indicating that the instruction has a second byte

that also needs to be decoded by microcode.

This second byte, called the ModR/M byte, specifies that memory addressing mode or registers that the instruction uses.

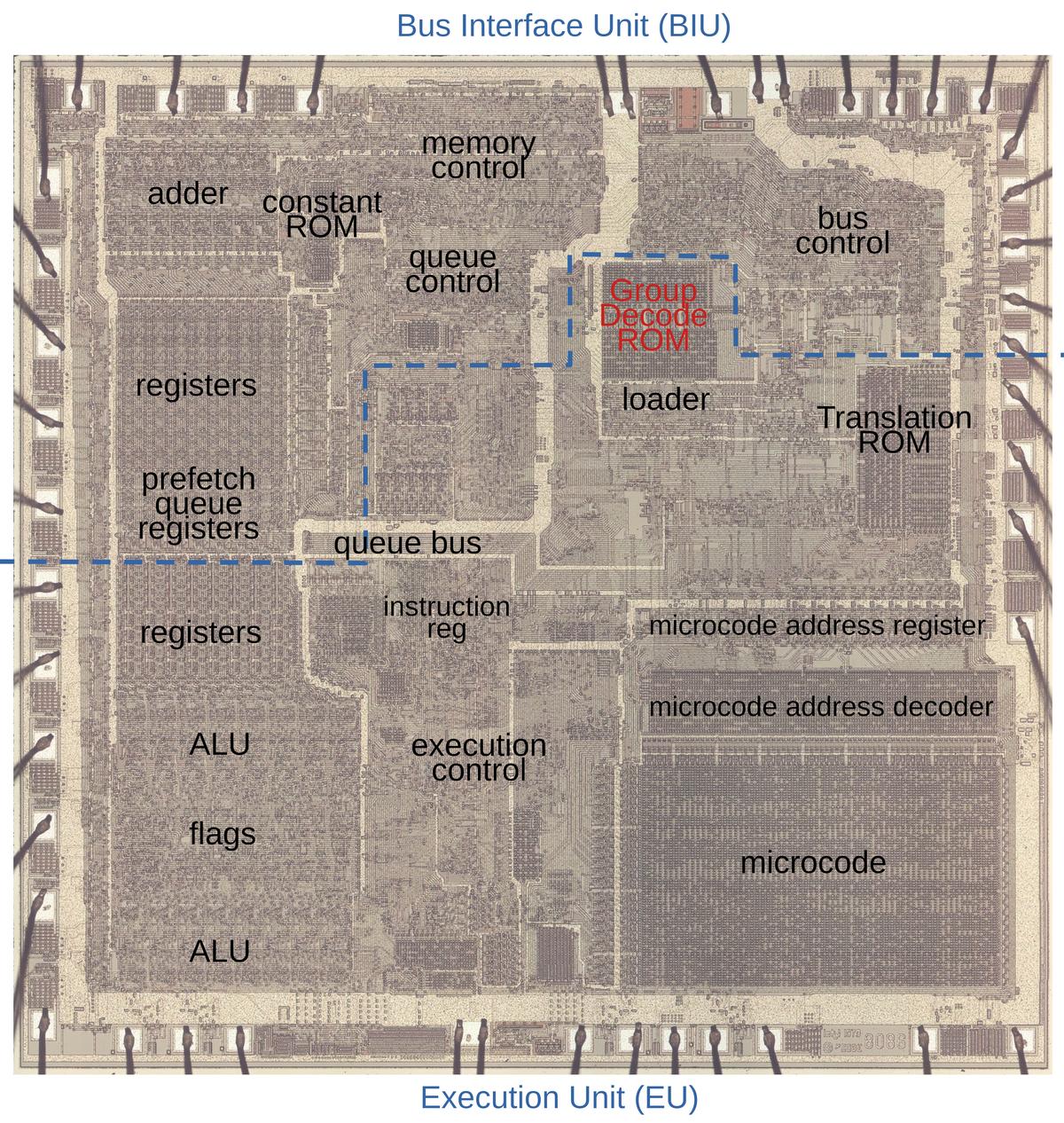

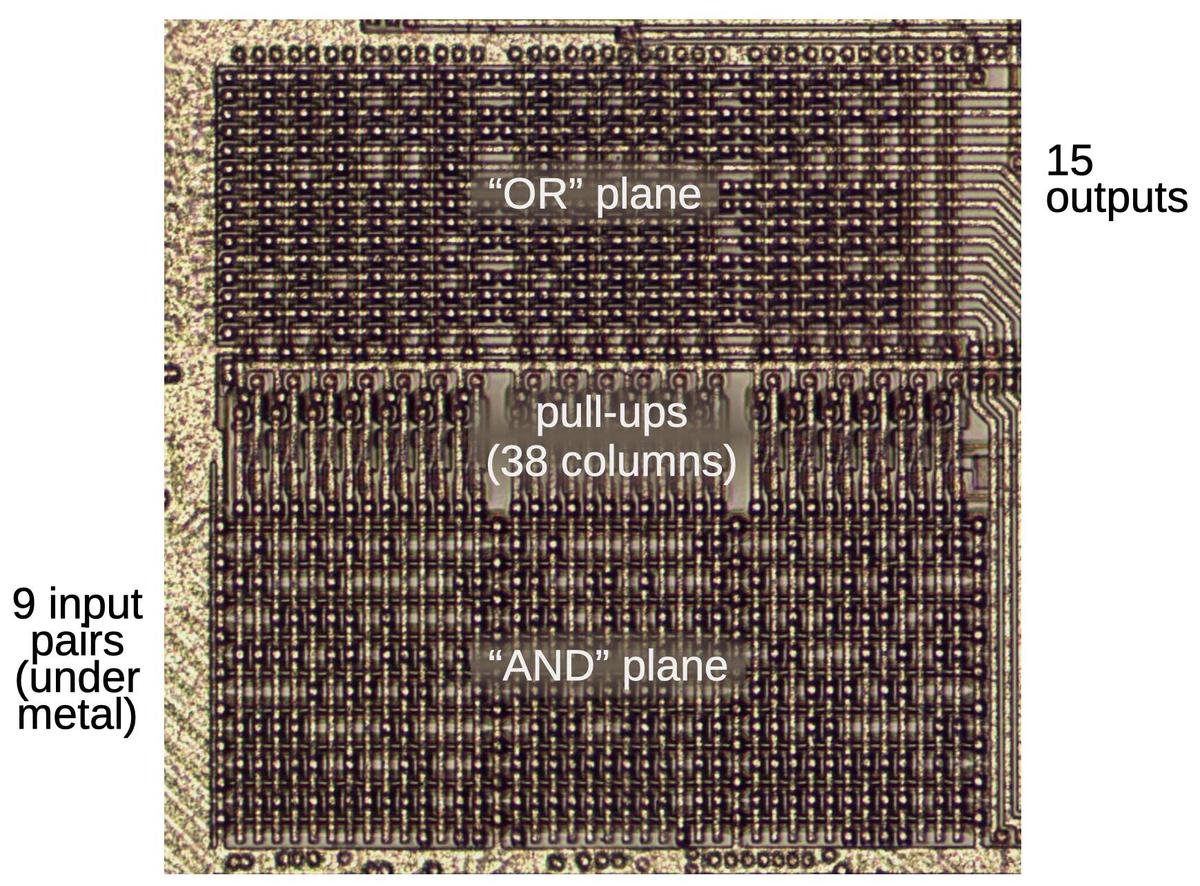

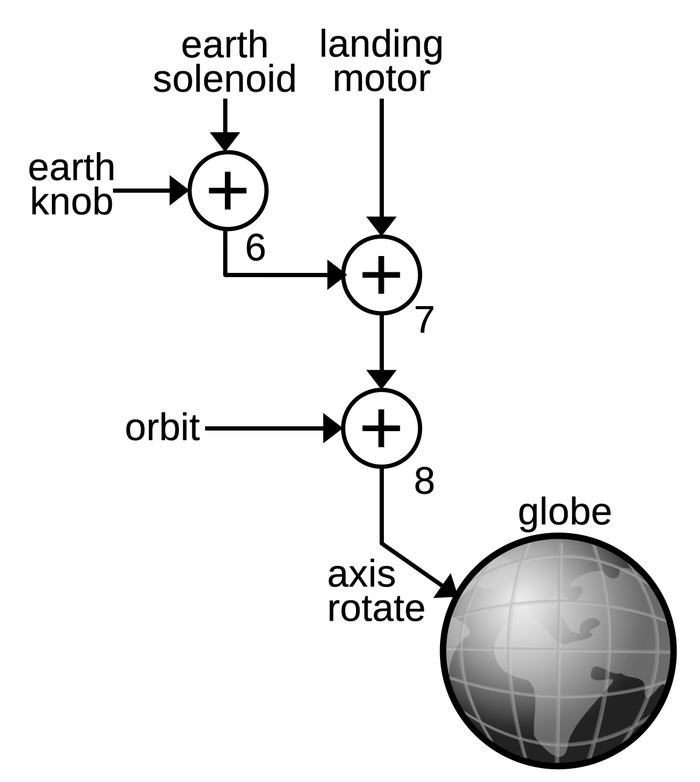

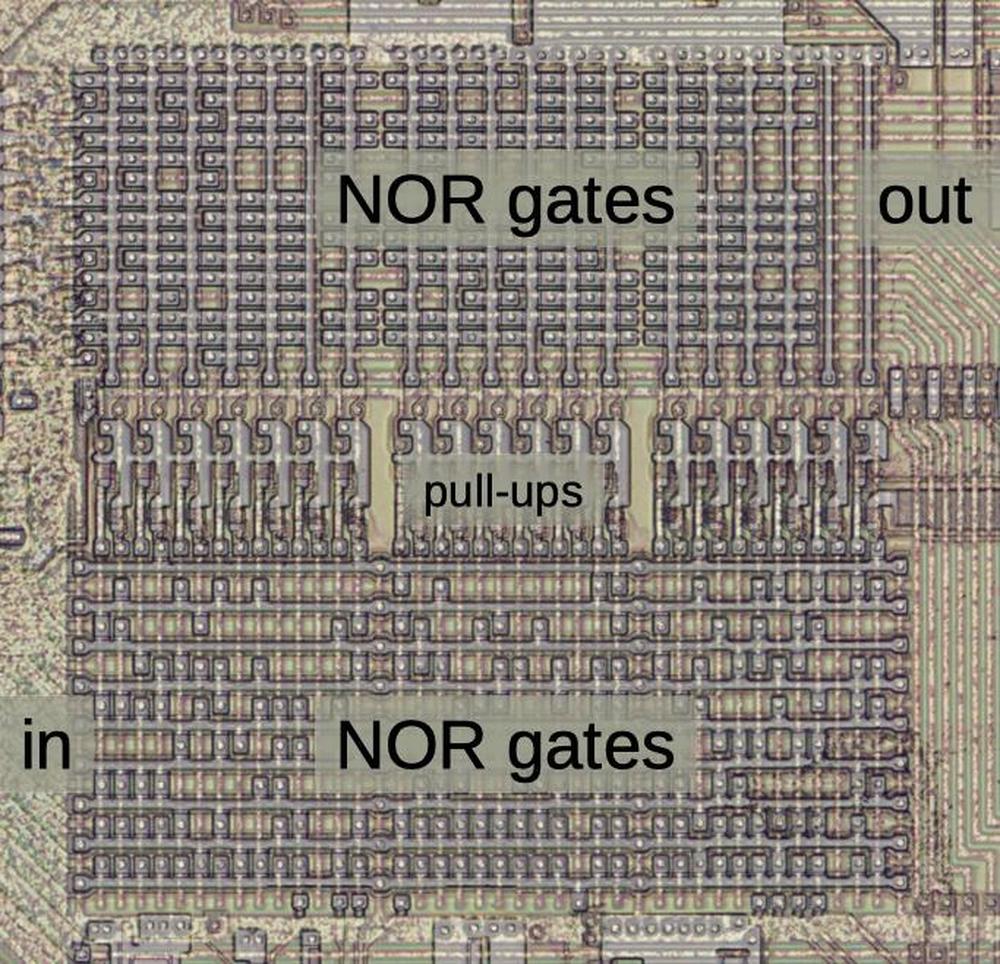

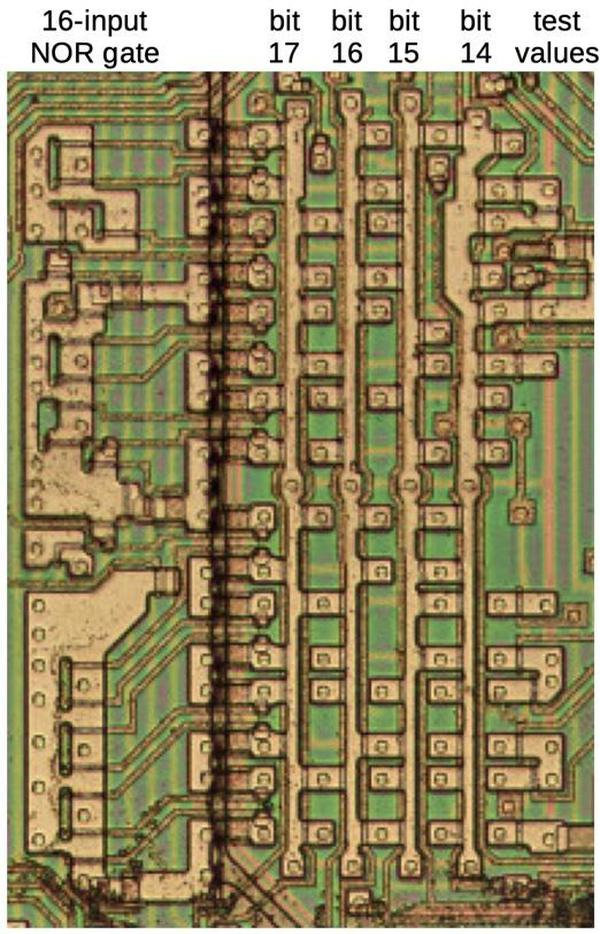

The next step is the microcode's address decoder circuit, which determines where to start executing microcode based on the opcode. Conceptually, you can think of the microcode as stored in a ROM, indexed by the instruction opcode and a few sequence bits. However, since many instructions can use the same microcode, it would be inefficient to store duplicate copies of these routines. Instead, the microcode address decoder permits multiple instructions to reference the same entries in the ROM. This decoding circuitry is similar to a PLA (Programmable Logic Array) so it matches bit patterns to determine a particular starting point. This turns out to be important for undocumented instructions since undocumented instructions often match the pattern for a "real" instruction, making the undocumented instruction an alias.

The 8086 has several internal registers that are invisible to the programmer but are used by the microcode.

Memory accesses use the Indirect (IND) and Operand (OPR) registers; the IND register holds the address in the segment,

while the OPR register holds the data value that is read or written.

Although these registers are normally not accessible by the programmer, some undocumented instructions provide access to these registers, as will be described later.

The Arithmetic/Logic Unit (ALU) performs arithmetic, logical, and shift operations in the 8086.

The ALU uses three internal registers: tmpA, tmpB, and tmpC. An ALU operation requires two micro-instructions.

The first micro-instruction specifies the operation (such as ADD) and the temporary register that holds one argument (e.g. tmpA);

the second argument is always in tmpB.

A following micro-instruction can access the ALU result through the pseudo-register Σ (sigma).

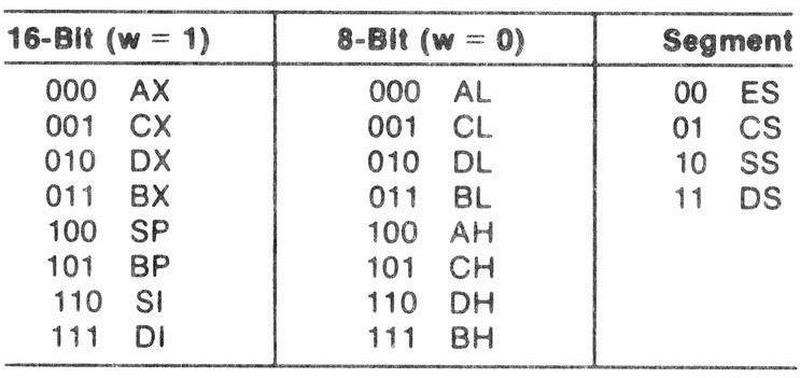

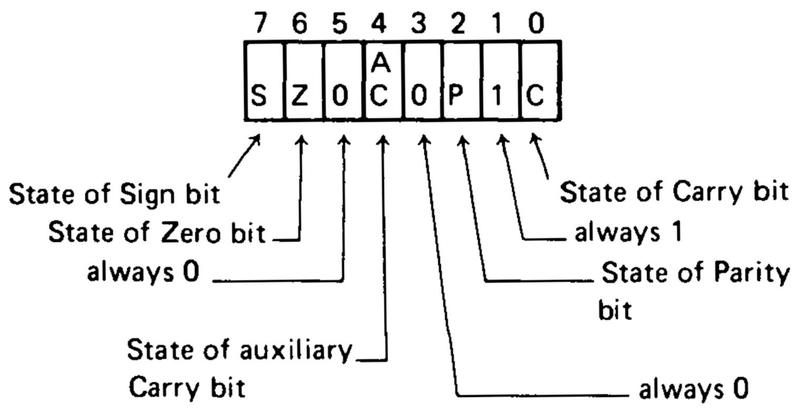

The ModR/M byte

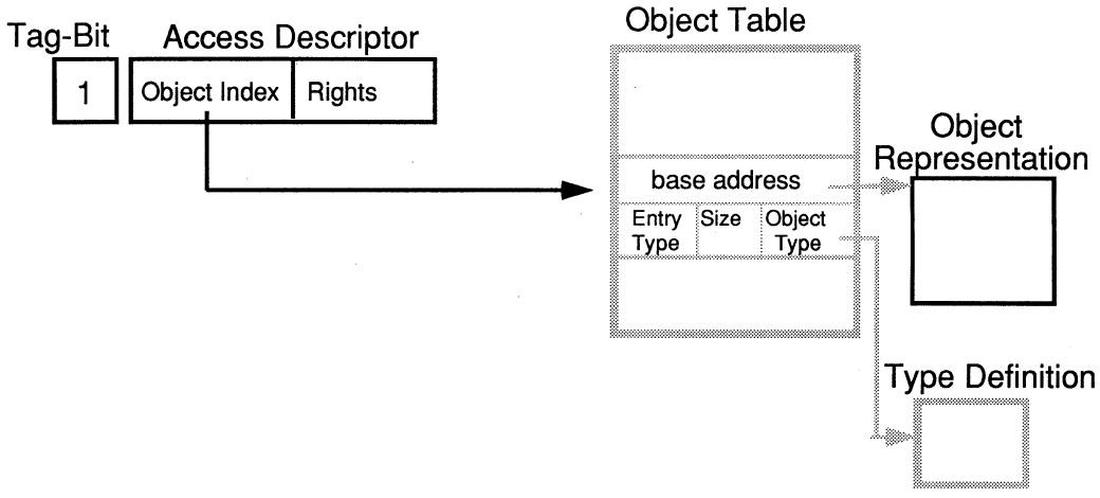

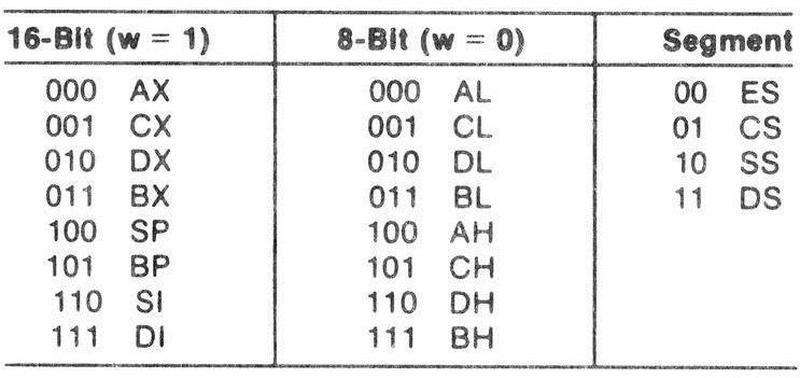

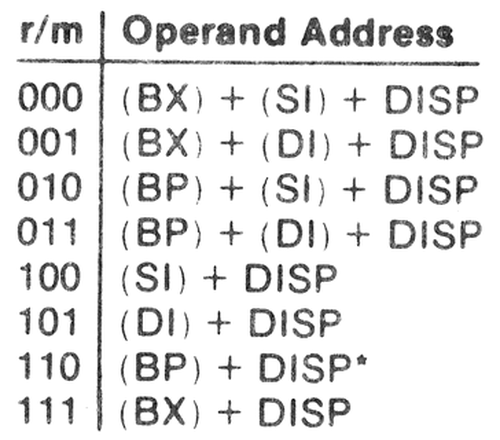

A fundamental part of the 8086 instruction format is the ModR/M byte, a byte that specifies addressing for many instructions. The 8086 has a variety of addressing modes, so the ModR/M byte is somewhat complicated. Normally it specifies one memory address and one register. The memory address is specified through one of eight addressing modes (below) along with an optional 8- or 16-bit displacement in the instruction. Instead of a memory address, the ModR/M byte can also specify a second register. For a few opcodes, the ModR/M byte selects what instruction to execute rather than a register.

https://static.righto.com/images/8086-ad-undoc/modrm.png">

The implementation of the ModR/M byte plays an important role in the behavior of undocumented instructions.

Support for this byte is implemented in both microcode and hardware.

The various memory address modes above are implemented by microcode subroutines, which compute the appropriate memory address and

perform a read if necessary.

The subroutine leaves the memory address in the IND register, and if a read is performed, the value is in the OPR register.

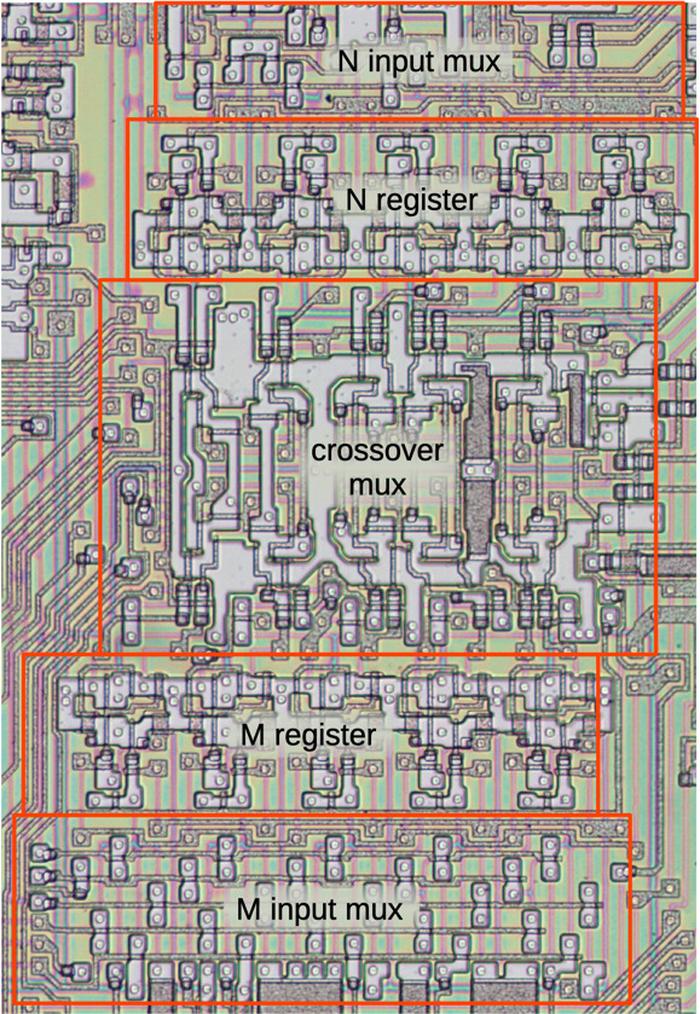

The hardware hides the ModR/M byte's selection of memory versus register, by making the value available through the pseudo-register M, while the second register is available through N.

Thus, the microcode for an instruction doesn't need to know if the value was in memory or a register, or which register was selected.

The Group Decode ROM examines the first byte of the instruction to determine if a ModR/M byte is present, and if a read

is required.

If the ModR/M byte specifies memory, the Translation ROM determines which micro-subroutines to call before handling the

instruction itself.

For more on the ModR/M byte, see my post on https://www.righto.com/2023/02/8086-modrm-addressing.html">Reverse-engineering the ModR/M addressing microcode.

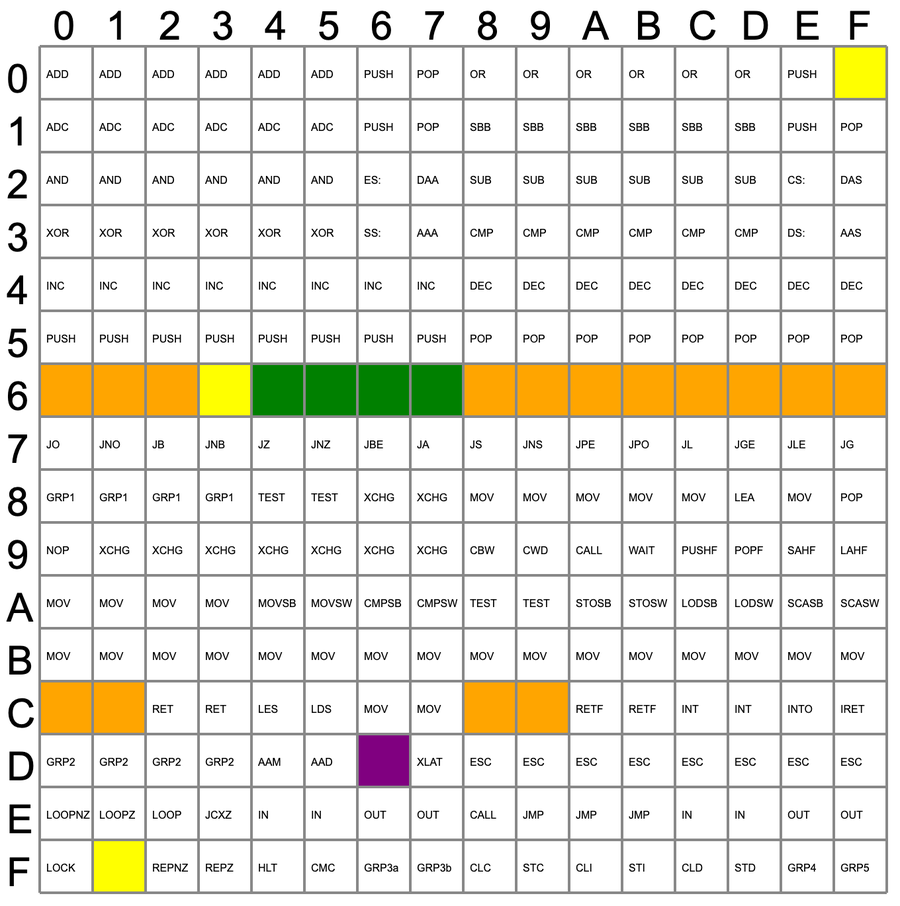

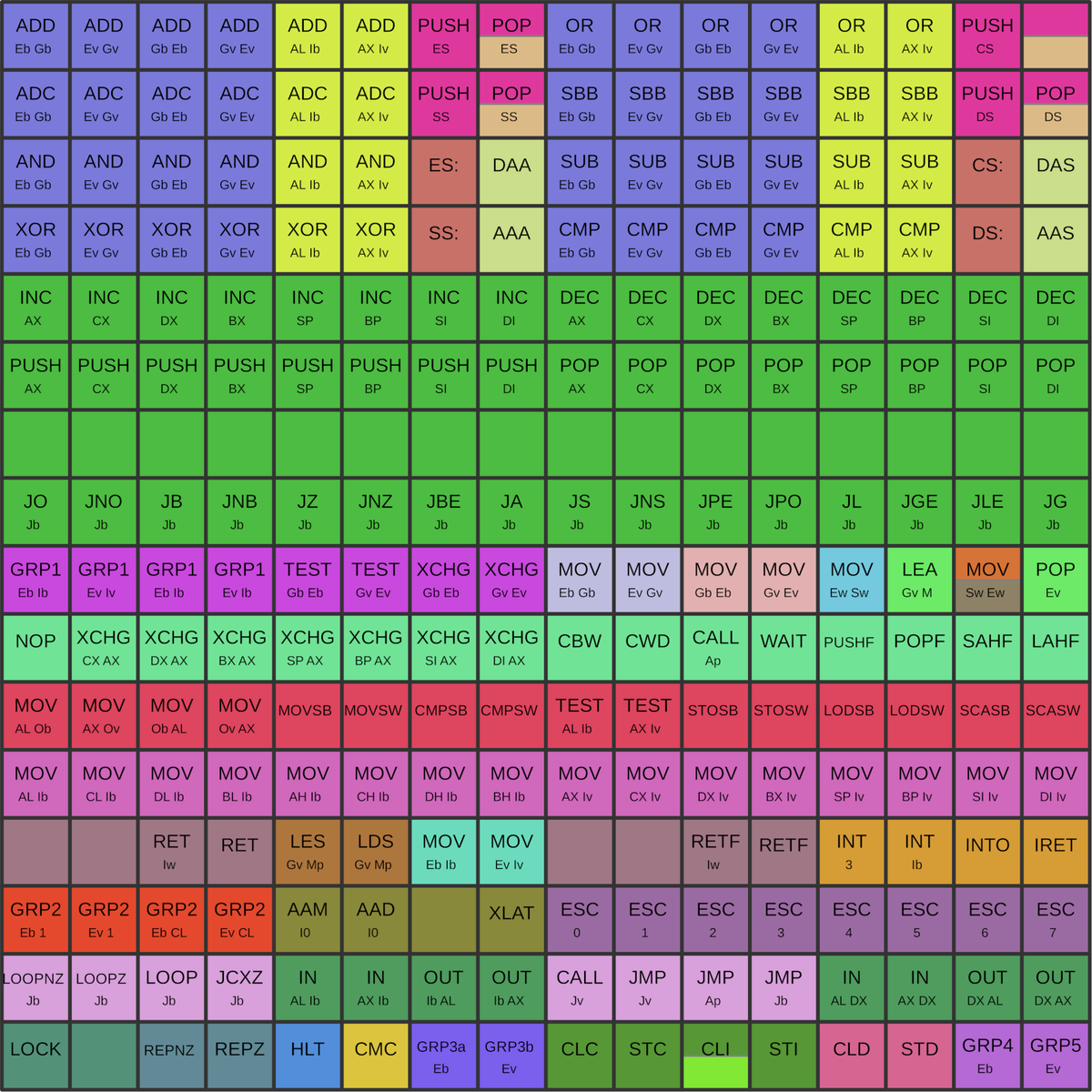

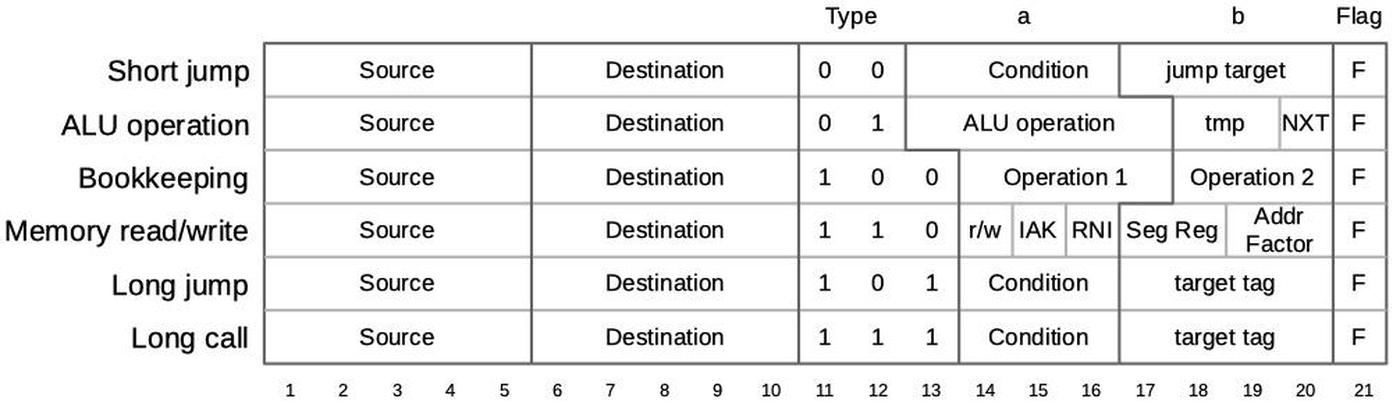

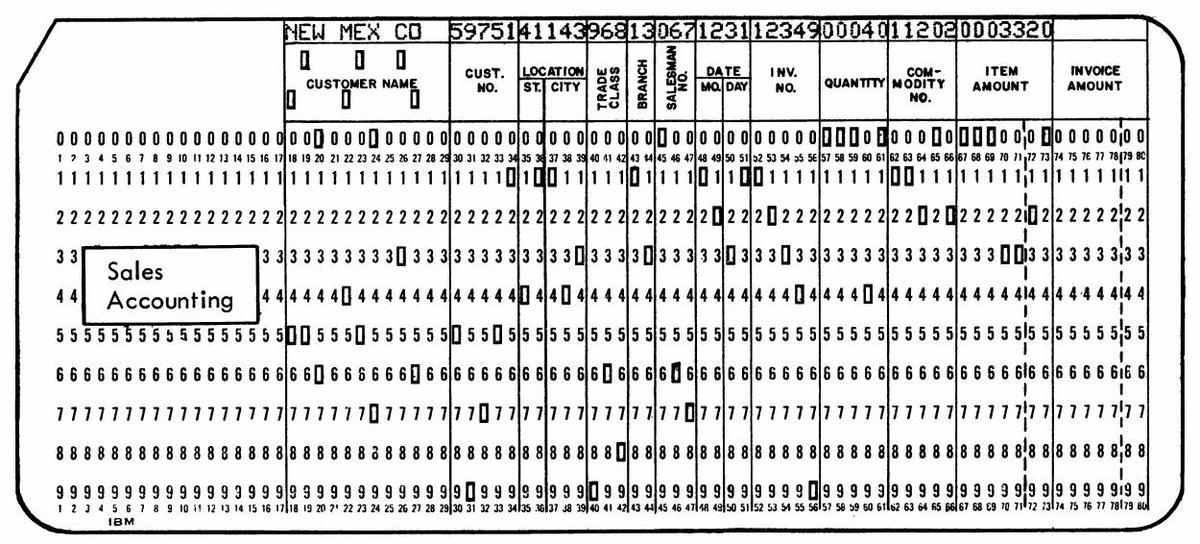

Holes in the opcode table

The first byte of the instruction is a value from 00 to FF in hex.

Almost all of these opcode values correspond to documented 8086 instructions, but there are a few exceptions, "holes" in the opcode table.

The table below shows the 256 first-byte opcodes for the 8086, from hex 00 to FF. Valid opcodes for the 8086 are in white;

the colored opcodes are undefined and interesting to examine.

Orange, yellow, and green opcodes were given meaning in the 80186, 80286, and 80386 respectively.

The purple opcode is unusual: it was implemented in the 8086 and later processors but not documented.2

In this section, I'll examine the microcode for these opcode holes.

D6: SALC

The opcode D6 (purple above) performs a well-known but undocumented operation that is typically called SALC, for Set AL to Carry.

This instruction sets the AL register to 0 if the carry flag is 0, and sets the AL register to FF if the carry flag is 1.

The curious thing about this undocumented instruction is that it exists in all x86 CPUs, but Intel didn't mention it until 2017.

Intel probably put this instruction into the processor deliberately as a copyright trap.

The idea is that if a company created a copy of the 8086 processor and the processor included the SALC instruction, this

would prove that the company had copied Intel's microcode and thus had potentially violated Intel's copyright on the microcode.

This came to light when NEC created improved versions of the 8086, the NEC V20 and V30 microprocessors, and was sued by Intel.

Intel analyzed NEC's microcode but was disappointed to find that NEC's chip did not include the hidden instruction, showing

that NEC hadn't copied the microcode.3

Although a Federal judge ruled in 1989 that NEC hadn't infringed

Intel's copyright, the 5-year trial ruined NEC's market momentum.

The SALC instruction is implemented with three micro-instructions, shown below.4

The first micro-instruction jumps if the carry (CY) is set.

If not, the next instruction moves 0 to the AL register. RNI (Run Next Instruction) ends the microcode execution

causing the next machine instruction to run.

If the carry was set, all-ones (i.e. FF hex) is moved to the AL register and RNI ends the microcode sequence.

JMPS CY 2 SALC: jump on carry

ZERO → AL RNI Move 0 to AL, run next instruction

ONES → AL RNI 2:Move FF to AL, run next instruction

0F: POP CS

The 0F opcode is the first hole in the opcode table.

The 8086 has instructions to push and pop the four segment registers, except opcode 0F is undefined where POP CS should be.

This opcode performs POP CS successfully, so the question is why is it undefined?

The reason is that POP CS is essentially useless and doesn't do what you'd expect, so Intel figured it was best not

to document it.

To understand why POP CS is useless, I need to step back and explain the 8086's segment registers.

The 8086 has a 20-bit address space, but 16-bit registers.

To make this work, the 8086 has the concept of segments: memory is accessed in 64K chunks called segments, which are positioned

in the 1-megabyte address space.

Specifically, there are four segments: Code Segment, Stack Segment, Data Segment, and Extra Segment,

with four segment registers that define the start of the segment: CS, SS, DS, and ES.

An inconvenient part of segment addressing is that if you want to access more than 64K, you need to change the segment register.

So you might push the data segment register, change it temporarily so you can access a new part of memory, and then pop the old data segment

register value off the stack.

This would use the PUSH DS and POP DS instructions.

But why not POP CS?

The 8086 executes code from the code segment, with the instruction pointer (IP) tracking the location in the code segment.

The main problem with POP CS is that it changes the code segment, but not the instruction pointer, so now you are executing

code at the old offset in a new segment.

Unless you line up your code extremely carefully, the result is that you're jumping to an unexpected place in memory.

(Normally, you want to change CS and the instruction pointer at the same time, using a CALL or JMP instruction.)

The second problem with POP CS is prefetching.

For efficiency, the 8086 prefetches instructions before they are needed, storing them in an 8-byte prefetch queue.

When you perform a jump, for instance, the microcode flushes the prefetch queue so execution will continue with the

new instructions, rather than the old instructions.

However, the instructions that pop a segment register don't flush the prefetch buffer.

Thus, POP CS not only jumps to an unexpected location in memory, but it will execute an unpredictable number of instructions

from the old code path.

The POP segment register microcode below packs a lot into three micro-instructions.

The first micro-instruction pops a value from the stack.

Specifically, it moves the stack pointer (SP) to the Indirect (IND) register.

The Indirect register is an internal register, invisible to the programmer, that holds the address offset for memory

accesses.

The first micro-instruction also performs a memory read (R) from the stack segment (SS) and then increments IND

by 2 (P2, plus 2).

The second micro-instruction moves IND to the stack pointer, updating the stack pointer with the new value.

It also tells the microcode engine that this micro-instruction is the next-to-last (NXT) and the next machine instruction

can be started.

The final micro-instruction moves the value read from memory to the appropriate segment register and runs the next instruction.

Specifically, reads and writes put data in the internal OPR (Operand) register.

The hardware uses the register N to indicate the register specified by the instruction.

That is, the value will be stored in the CS, DS, ES, or SS register, depending on the bit pattern in the instruction.

Thus, the same microcode works for all four segment registers.

This is why POP CS works even though POP CS wasn't explicitly implemented in the microcode; it uses the common code.

SP → IND R SS,P2 POP sr: read from stack, compute IND plus 2 IND → SP NXT Put updated value in SP, start next instruction. OPR → N RNI Put stack value in specified segment register

But why does POP CS run this microcode in the first place?

The microcode to execute is selected based on the instruction, but multiple instructions can execute the same microcode.

You can think of the address decoder as pattern-matching on the instruction's bit patterns, where some of the bits can be ignored.

In this case, the POP sr microcode above is run by any instruction with the bit pattern 000??111, where a question mark

can be either a 0 or a 1.

You can verify that this pattern matches POP ES (07), POP SS (17), and POP DS (1F).

However, it also matches 0F, which is why the 0F opcode runs the above microcode and performs POP CS.

In other words, to make 0F do something other than POP CS would require additional circuitry, so it was easier to

leave the action implemented but undocumented.

60-6F: conditional jumps

One whole row of the opcode table is unused: values 60 to 6F.

These opcodes simply act the same as 70 to 7F, the conditional jump instructions.

The conditional jumps use the following microcode.

It fetches the jump offset from the instruction prefetch queue (Q) and puts the value into the ALU's tmpBL register,

the low byte of the tmpB register.

It tests the condition in the instruction (XC) and jumps to the RELJMP micro-subroutine if satisfied.

The RELJMP code (not shown) updates the program counter to perform the jump.

Q → tmpBL Jcond cb: Get offset from prefetch queue JMP XC RELJMP Test condition, if true jump to RELJMP routine RNI No jump: run next instruction

This code is executed for any instruction matching the bit pattern 011?????, i.e. anything from 60 to 7F.

The condition is specified by the four low bits of the instruction.

The result is that any instruction 60-6F is an alias for the corresponding conditional jump 70-7F.

C0, C8: RET/RETF imm

These undocumented opcodes act like a return instruction, specifically RET imm16 (source).

Specifically, the instruction C0 is the same as C2, near return, while C8 is the same as CA, far return.

The microcode below is executed for the instruction bits 1100?0?0, so it is executed for C0, C2, C8, and CA.

It gets two bytes from the instruction prefetch queue (Q) and puts them in the tmpA register.

Next, it calls FARRET, which performs either a near return (popping PC from the stack) or a far return (popping PC and CS

from the stack). Finally, it adds the original argument to the SP, equivalent to popping that many bytes.

Q → tmpAL ADD tmpA RET/RETF iw: Get word from prefetch, set up ADD Q → tmpAH CALL FARRET Call Far Return micro-subroutine IND → tmpB Move SP (in IND) to tmpB for ADD Σ → SP RNI Put sum in Stack Pointer, end

One tricky part is that the FARRET micro-subroutine examines bit 3 of the instruction to determine whether it does a near

return or a far return.

This is why documented instruction C2 is a near return and CA is a far return.

Since C0 and C8 run the same microcode, they will perform the same actions, a near return and a far return respectively.

C1: RET

The undocumented C1 opcode is identical to the documented C3, near return instruction.

The microcode below is executed for instruction bits 110000?1, i.e. C1 and C3.

The first micro-instruction reads from the Stack Pointer, incrementing IND by 2.

Prefetching is suspended and the prefetch queue is flushed, since execution will continue at a new location.

The Program Counter is updated with the value from the stack, read into the OPR register.

Finally, the updated address is put in the Stack Pointer and execution ends.

SP → IND R SS,P2 RET: Read from stack, increment by 2 SUSP Suspend prefetching OPR → PC FLUSH Update PC from stack, flush prefetch queue IND → SP RNI Update SP, run next instruction

C9: RET

The undocumented C9 opcode is identical to the documented CB, far return instruction.

This microcode is executed for instruction bits 110010?1, i.e. C9 and CB, so C9 is identical to CB.

The microcode below simply calls the FARRET micro-subroutine to pop the Program Counter and CS register.

Then the new value is stored into the Stack Pointer.

One subtlety is that FARRET looks at bit 3 of the instruction to switch between a near return and a far return, as

described earlier.

Since C9 and CB both have bit 3 set, they both perform a far return.

CALL FARRET RETF: call FARRET routine

IND → SP RNI Update stack pointer, run next instruction

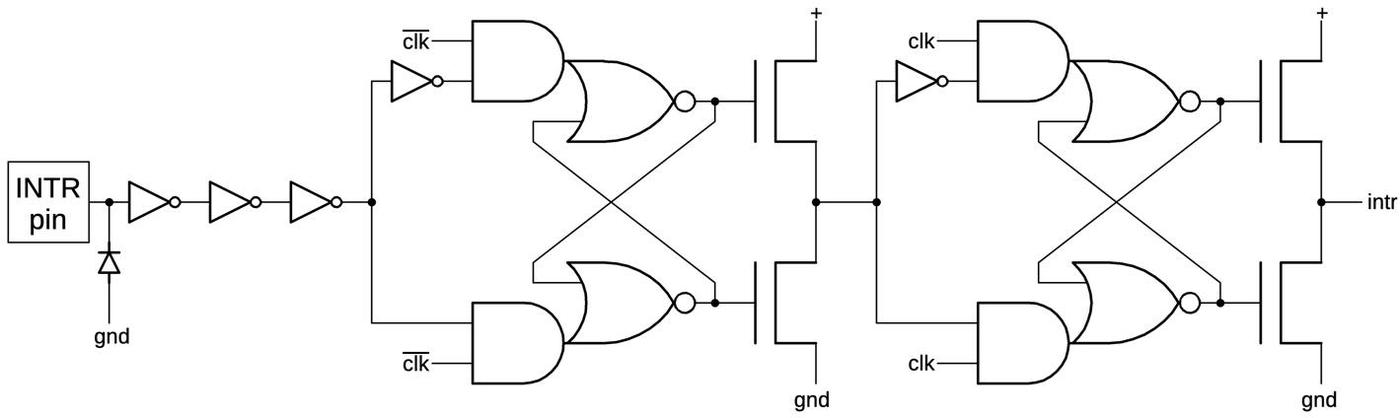

F1: LOCK prefix

The final hole in the opcode table is F1.

This opcode is different because it is implemented in logic rather than microcode.

The Group Decode ROM indicates that F1 is a prefix, one-byte logic, and LOCK.

The Group Decode outputs are the same as F0, so F1 also acts as a LOCK prefix.

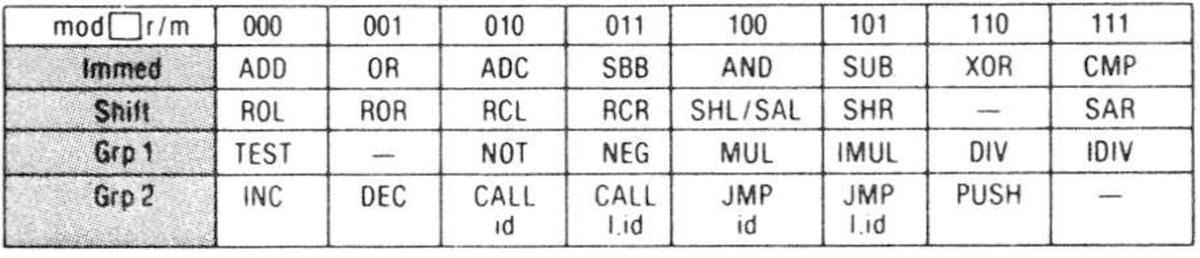

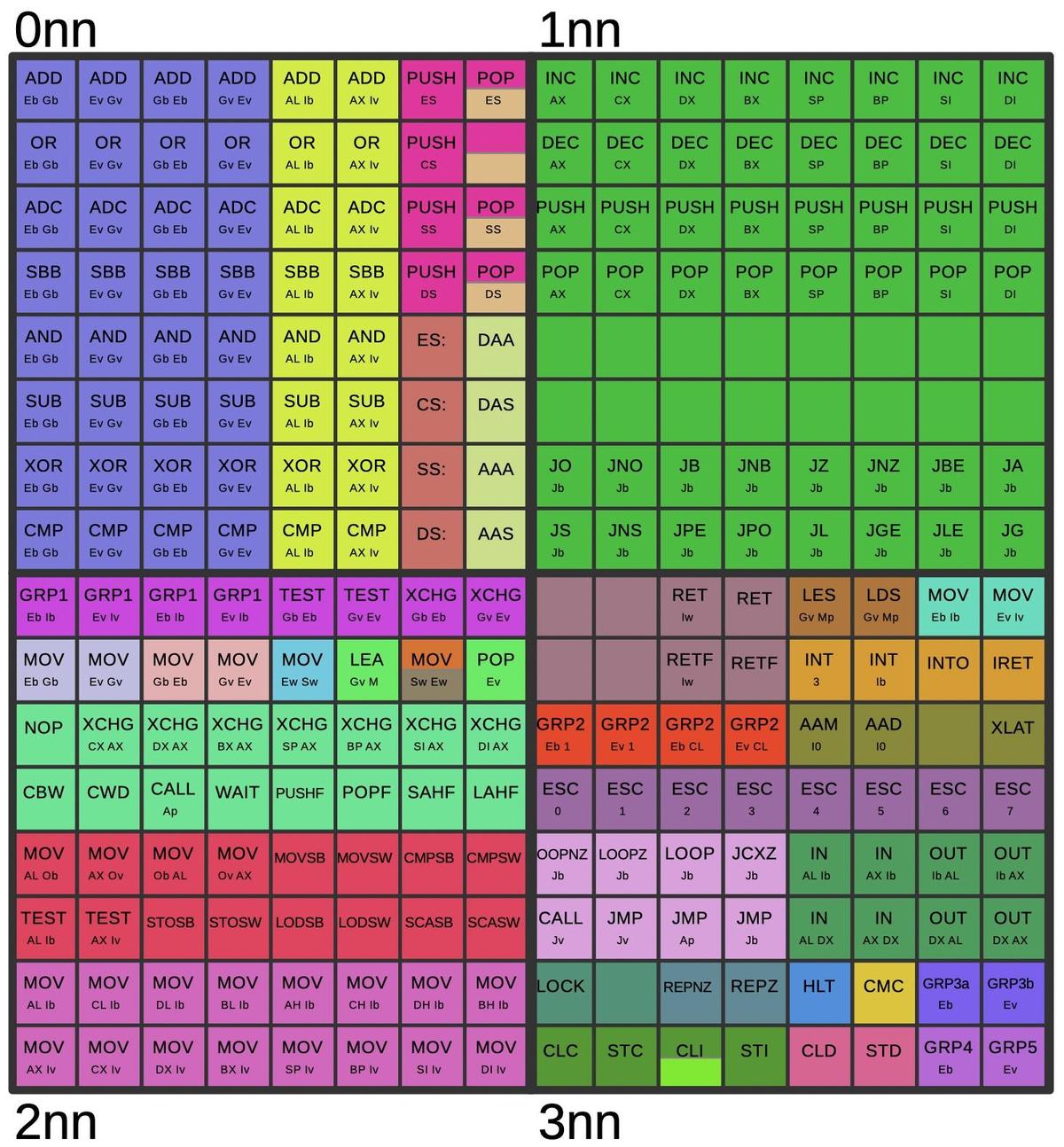

Holes in two-byte opcodes

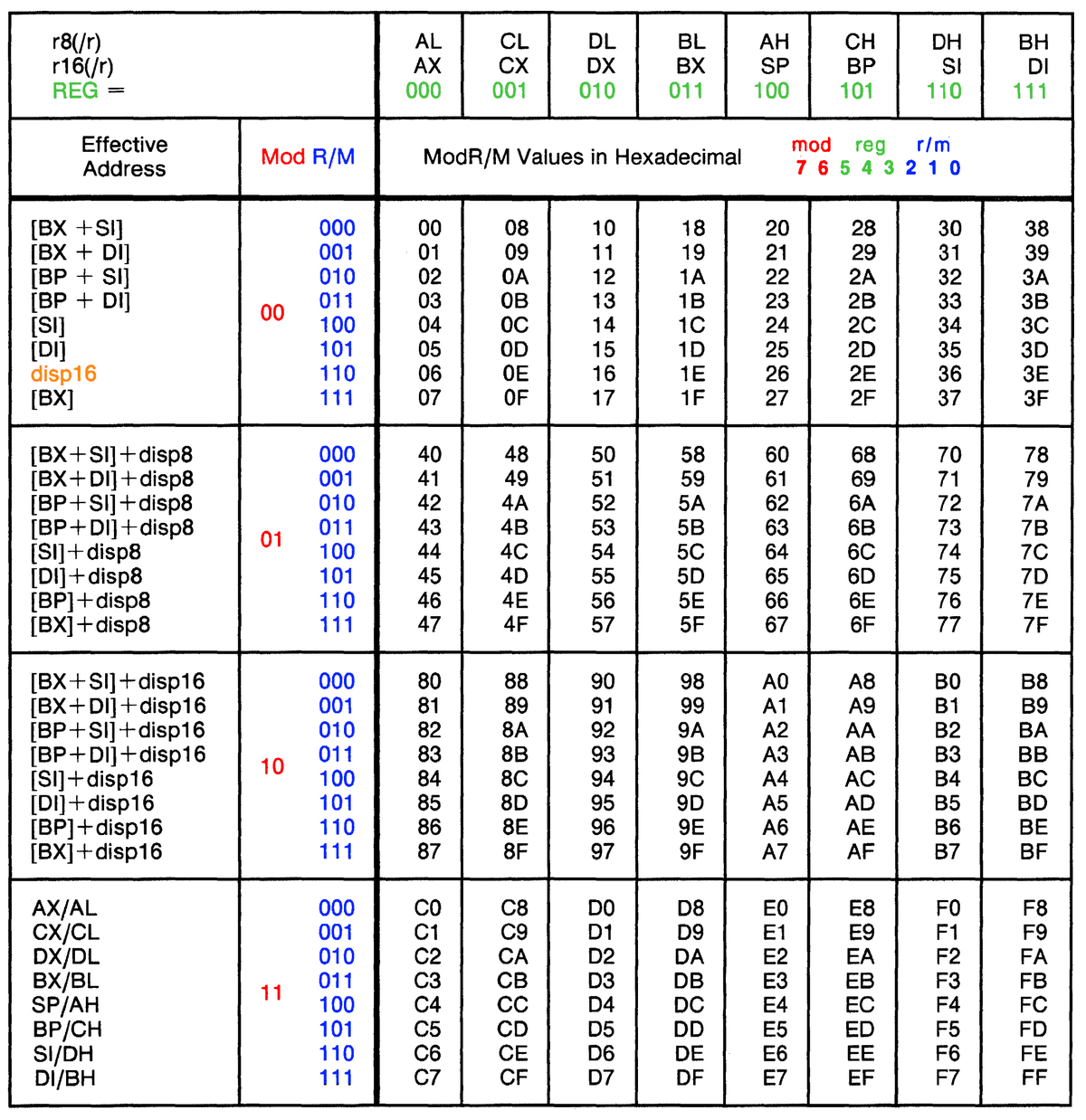

For most of the 8086 instructions, the first byte specifies the instruction.

However, the 8086 has a few instructions where the second byte specifies the instruction: the reg field of the ModR/M byte provides an opcode extension that selects the instruction.5

These fall into four categories which Intel labeled "Immed", "Shift", "Group 1", and "Group 2", corresponding to opcodes 80-83, D0-D3,

F6-F7, and FE-FF.

The table below shows how the second byte selects the instruction.

Note that "Shift", "Group 1", and "Group 2" all have gaps, resulting in undocumented values.

These sets of instructions are implemented in two completely different ways.

The "Immed" and "Shift" instructions run microcode in the standard way, selected by the first byte.

For a typical arithmetic/logic instruction such as ADD, bits 5-3 of the first instruction byte are latched into the X register to indicate

which ALU operation to perform.

The microcode specifies a generic ALU operation, while the X register controls whether the operation is an ADD, SUB, XOR, or

so forth.

However, the Group Decode ROM indicates that for the special "Immed" and "Shift" instructions, the X register latches the bits

from the second byte.

Thus, when the microcode executes a generic ALU operation, it ends up with the one specified in the second byte.6

The "Group 1" and "Group 2" instructions (F0-F1, FE-FF), however, run different microcode for each instruction.

Bits 5-3 of the second byte replace bits 2-0 of the instruction before executing the microcode.

Thus, F0 and F1 act as if they are opcodes in the range F0-F7, while FE and FF act as if they are opcodes in the range F8-FF.

Thus, each instruction specified by the second byte can have its own microcode, unlike the "Immed" and "Shift" instructions.

The trick that makes this work is that all the "real" opcodes in the range F0-FF are implemented in logic, not microcode,

so there are no collisions.

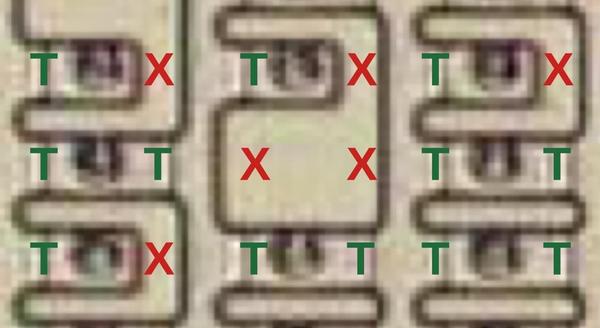

The hole in "Shift": SETMO, D0..D3/6

There is a "hole" in the list of shift operations when the second byte has the bits 110 (6).

(This is typically expressed as D0/6 and so forth; the value after the slash is the opcode-selection bits in the ModR/M byte.)

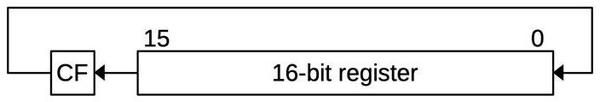

Internally, this value selects the ALU's SETMO (Set Minus One) operation, which simply returns FF or FFFF, for a byte or word operation respectively.7

The microcode below is executed for 1101000? bit patterns patterns (D0 and D1).

The first instruction gets the value from the M register and sets up the ALU to do whatever operation was

specified in the instruction (indicated by XI).

Thus, the same microcode is used for all the "Shift" instructions, including SETMO.

The result is written back to M. If no writeback to memory is required (NWB), then RNI runs the next instruction, ending

the microcode sequence.

However, if the result is going to memory, then the last line writes the value to memory.

M → tmpB XI tmpB, NXT rot rm, 1: get argument, set up ALU Σ → M NWB,RNI F Store result, maybe run next instruction W DS,P0 RNI Write result to memory

The D2 and D3 instructions (1101001?) perform a variable number of shifts, specified by the CL register, so they use different microcode (below).

This microcode loops the number of times specified by CL, but the control flow is a bit tricky to avoid shifting if

the intial counter value is 0.

The code sets up the ALU to pass the counter (in tmpA) unmodified the first time (PASS) and jumps to 4, which

updates the counter and sets up the ALU for the shift operation (XI).

If the counter is not zero, it jumps back to 3, which performs the previously-specified shift and sets up

the ALU to decrement the counter (DEC).

This time, the code at 4 decrements the counter.

The loop continues until the counter reaches zero. The microcode stores the result as in the previous microcode.

ZERO → tmpA rot rm,CL: 0 to tmpA CX → tmpAL PASS tmpA Get count to tmpAL, set up ALU to pass through M → tmpB JMPS 4 Get value, jump to loop (4) Σ → tmpB DEC tmpA F 3: Update result, set up decrement of count Σ → tmpA XI tmpB 4: update count in tmpA, set up ALU JMPS NZ 3 Loop if count not zero tmpB → M NWB,RNI Store result, maybe run next instruction W DS,P0 RNI Write result to memory

The hole in "group 1": TEST, F6/1 and F7/1

The F6 and F7 opcodes are in "group 1", with the specific instruction specified by bits 5-3 of the second byte.

The second-byte table showed a hole for the 001 bit sequence.

As explained earlier, these bits replace the low-order bits of the instruction, so F6 with 001 is processed as if it were

the opcode F1.

The microcode below matches against instruction bits 1111000?, so F6/1 and F7/1 have the same effect as F6/0 and F7/1 respectively,

that is, the byte and word TEST instructions.

The microcode below gets one or two bytes from the prefetch queue (Q); the L8 condition tests if the operation is

an 8-bit (i.e. byte) operation and skips the second micro-instruction.

The third micro-instruction ANDs the argument and the fetched value.

The condition flags (F) are set based on the result, but the result itself is discarded.

Thus, the TEST instruction tests a value against a mask, seeing if any bits are set.

Q → tmpBL JMPS L8 2 TEST rm,i: Get byte, jump if operation length = 8 Q → tmpBH Get second byte from the prefetch queue M → tmpA AND tmpA, NXT 2: Get argument, AND with fetched value Σ → no dest RNI F Discard result but set flags.

I explained the processing of these "Group 3" instructions in more detail in my microcode article.

The hole in "group 2": PUSH, FE/7 and FF/7

The FE and FF opcodes are in "group 2", which has a hole for the 111 bit sequence in the second byte.

After replacement, this will be processed as the FF opcode, which matches the pattern 1111111?.

In other words, the instruction will be processed the same as the 110 bit pattern, which is PUSH.

The microcode gets the Stack Pointer, sets up the ALU to decrement it by 2.

The new value is written to SP and IND. Finally, the register value is written to stack memory.

SP → tmpA DEC2 tmpA PUSH rm: set up decrement SP by 2 Σ → IND Decremented SP to IND Σ → SP Decremented SP to SP M → OPR W SS,P0 RNI Write the value to memory, done

82 and 83 "Immed" group

Opcodes 80-83 are the "Immed" group, performing one of eight arithmetic operations, specified in the ModR/M byte.

The four opcodes differ in the size of the values: opcode 80 applies an 8-bit immediate value to an 8-bit register, 81 applies a 16-bit

value to a 16-bit register, 82 applies an 8-bit value to an 8-bit register, and 83 applies an 8-bit value to a 16-bit register.

The opcode 82 has the strange situation that some sources say it is undocumented, but it shows up in some Intel documentation as a valid bit combination (e.g. below).

Note that 80 and 82 have the 8-bit to 8-bit action, so the 82 opcode is redundant.

The microcode below is used for all four opcodes.

If the ModR/M byte specifies memory, the appropriate micro-subroutine is called to compute the effective address in IND,

and fetch the byte or word into OPR.

The first two instructions below get the two immediate data bytes from the prefetch queue; for an 8-bit operation, the second byte

is skipped.

Next, the second argument M is loaded into tmpA and the desired ALU operation (XI) is configured.

The result Σ is stored into the specified register M and the operation may terminate with RNI.

But if the ModR/M byte specified memory, the following write micro-operation saves the value to memory.

Q → tmpBL JMPS L8 2 alu rm,i: get byte, test if 8-bit op Q → tmpBH Maybe get second byte M → tmpA XI tmpA, NXT 2: Σ → M NWB,RNI F Save result, update flags, done if no memory writeback W DS,P0 RNI Write result to memory if needed

The tricky part of this is the L8 condition, which tests if the operation is 8-bit.

You might think that bit 0 acts as the byte/word bit in a nice, orthogonal way, but the 8086 has a bunch of special cases.

Bit 0 of the instruction typically selects between a byte and a word operation, but there are a bunch of special cases.

The Group Decode ROM creates a signal indicating if bit 0 should be used as the byte/word bit.

But it generates a second signal indicating that an instruction should be forced to operate on bytes, for instructions

such as DAA and XLAT.

Another Group Decode ROM signal indicates that bit 3 of the instruction should select byte or word; this

is used for the MOV instructions with opcodes Bx.

Yet another Group Decode ROM signal indicates that inverted bit 1 of the instruction should select byte or word;

this is used for a few opcodes, including 80-87.

The important thing here is that for the opcodes under discussion (80-83), the L8 micro-condition uses both bits 0 and 1

to determine if the instruction is 8 bits or not.

The result is that only opcode 81 is considered 16-bit by the L8 test, so it is the only one that uses two immediate bytes

from the instruction.

However, the register operations use only bit 0 to select a byte or word transfer.

The result is that opcode 83 has the unusual behavior of using an 8-bit immediate operand with a 16-bit register.

In this case, the 8-bit value is sign-extended to form a 16-bit value. That is, the top bit of the 8-bit value fills

the entire upper half of the 16-bit value,

converting an 8-bit signed value to a 16-bit signed value (e.g. -1 is FF, which becomes FFFF).

This makes sense for arithmetic operations, but not much sense for logical operations.

Intel documentation is inconsistent about which opcodes are listed for which instructions.

Intel opcode maps generally define opcodes 80-83.

However, lists of specific instructions show opcodes 80, 81, and 83 for arithmetic operations but only 80 and 81 for logical operations.8

That is, Intel omits the redundant 82 opcode as well as omitting logic operations that perform sign-extension (83).

More FE holes

For the "group 2" instructions, the FE opcode performs a byte operation while FF performs a word operation.

Many of these operations don't make sense for bytes: CALL, JMP, and PUSH.

(The only instructions supported for FE are INC and DEC.) But what happens if you use the unsupported instructions?

The remainder of this section examines those cases and shows that the results are not useful.

CALL: FE/2

This instruction performs an indirect subroutine call within a segment, reading the target address from the memory location specified by the ModR/M byte.

The microcode below is a bit convoluted because the code falls through into the shared NEARCALL routine, so there is

some unnecessary register movement.

Before this microcode executes, the appropriate ModR/M micro-subroutine will read the target address from memory.

The code below copies the destination address from M to tmpB and stores it into the PC later in the code

to transfer execution.

The code suspends prefetching, corrects the PC to cancel the offset from prefetching, and flushes the prefetch queue.

Finally, it decrements the SP by two and writes the old PC to the stack.

M → tmpB SUSP CALL rm: read value, suspend prefetch SP → IND CORR Get SP, correct PC PC → OPR DEC2 tmpC Get PC to write, set up decrement tmpB → PC FLUSH NEARCALL: Update PC, flush prefetch IND → tmpC Get SP to decrement Σ → IND Decremented SP to IND Σ → SP W SS,P0 RNI Update SP, write old PC to stack

This code will mess up in two ways when executed as a byte instruction. First, when the destination address is read from memory, only a byte will be read, so the destination address will be corrupted. (I think that the behavior here depends on the bus hardware. The 8086 will ask for a byte from memory but will read the word that is placed on the bus. Thus, if memory returns a word, this part may operate correctly. The 8088's behavior will be different because of its 8-bit bus.) The second issue is writing the old PC to the stack because only a byte of the PC will be written. Thus, when the code returns from the subroutine call, the return address will be corrupt.

CALL: FE/3

This instruction performs an indirect subroutine call between segments, reading the target address from the memory location specified by the ModR/M byte.

IND → tmpC INC2 tmpC CALL FAR rm: set up IND+2 Σ → IND R DS,P0 Read new CS, update IND OPR → tmpA DEC2 tmpC New CS to tmpA, set up SP-2 SP → tmpC SUSP FARCALL: Suspend prefetch Σ → IND CORR FARCALL2: Update IND, correct PC CS → OPR W SS,M2 Push old CS, decrement IND by 2 tmpA → CS PASS tmpC Update CS, set up for NEARCALL PC → OPR JMP NEARCALL Continue with NEARCALL

As in the previous CALL, this microcode will fail in multiple ways when executed in byte mode.

The new CS and PC addresses will be read from memory as bytes, which may or may not work.

Only a byte of the old CS and PC will be pushed to the stack.

JMP: FE/4

This instruction performs an indirect jump within a segment, reading the target address from the memory location specified by the ModR/M byte.

The microcode is short, since the ModR/M micro-subroutine does most of the work.

I believe this will have the same problem as the previous CALL instructions, that it will attempt to read a byte from

memory instead of a word.

SUSP JMP rm: Suspend prefetch

M → PC FLUSH RNI Update PC with new address, flush prefetch, done

JMP: FE/5

This instruction performs an indirect jump between segments, reading the new PC and CS values from the memory location specified by the ModR/M byte.

The ModR/M micro-subroutine reads the new PC address. This microcode increments IND and suspends prefetching.

It updates the PC, reads the new CS value from memory, and updates the CS.

As before, the reads from memory will read bytes instead of words, so this code will not meaningfully work in byte mode.

IND → tmpC INC2 tmpC JMP FAR rm: set up IND+2 Σ → IND SUSP Update IND, suspend prefetch tmpB → PC R DS,P0 Update PC, read new CS from memory OPR → CS FLUSH RNI Update CS, flush prefetch, done

PUSH: FE/6

This instruction pushes the register or memory value specified by the ModR/M byte. It decrements the SP by 2 and then writes the value to the stack. It will write one byte to the stack but decrements the SP by 2, so one byte of old stack data will be on the stack along with the data byte.

SP → tmpA DEC2 tmpA PUSH rm: Set up SP decrement Σ → IND Decremented value to IND Σ → SP Decremented value to SP M → OPR W SS,P0 RNI Write the data to the stack

Undocumented instruction values

The next category of undocumented instructions is where the first byte indicates a valid instruction, but there is something wrong with the second byte.

AAM: ASCII Adjust after Multiply

The AAM instruction is a fairly obscure one, designed to support binary-coded decimal

arithmetic (BCD).

After multiplying two BCD digits, you end up with a binary value between 0 and 81 (0×0 to 9×9).

If you want a BCD result, the AAM instruction converts this binary value to BCD, for instance splitting 81 into the

decimal digits 8 and 1, where the upper digit is 81 divided by 10, and the lower digit is 81 modulo 10.

The interesting thing about AAM is that the 2-byte instruction is D4 0A. You might notice that hex 0A is 10, and this

is not a coincidence.

There wasn't an easy way to get the value 10 in the microcode, so instead they made the instruction

provide that value in the second byte.

The undocumented (but well-known) part is that if you provide a value other than 10, the instruction will convert the binary input into

digits in that base. For example, if you provide 8 as the second byte, the instruction returns the value divided by 8

and the value modulo 8.

The microcode for AAM, below, sets up the registers. calls

the CORD (Core Division) micro-subroutine to perform the division,

and then puts the results into AH and AL.

In more detail, the CORD routine divides tmpA/tmpC by tmpB, putting the complement of the quotient in tmpC and leaving the remainder in tmpA.

(If you want to know how CORD works internally, see my division post.)

The important step is that the AAM microcode gets the divisor from the prefetch queue (Q).

After calling CORD, it sets up the ALU to perform a 1's complement of tmpC and puts the result (Σ) into AH.

It sets up the ALU to pass tmpA through unchanged, puts the result (Σ) into AL, and updates the flags accordingly (F).

Q → tmpB AAM: Move byte from prefetch to tmpB ZERO → tmpA Move 0 to tmpA AL → tmpC CALL CORD Move AL to tmpC, call CORD. COM1 tmpC Set ALU to complement Σ → AH PASS tmpA, NXT Complement AL to AH Σ → AL RNI F Pass tmpA through ALU to set flags

The interesting thing is why this code has undocumented behavior.

The 8086's microcode only has support for the constants 0 and all-1's (FF or FFFF), but the microcode needs to divide by 10.

One solution would be to implement an additional micro-instruction and more circuitry to provide the constant 10, but every

transistor was precious back then.

Instead, the designers took the approach of simply putting the number 10 as the second byte of the instruction and loading the

constant from there.

Since the AAM instruction is not used very much, making the instruction two bytes long wasn't much of a drawback.

But if you put a different number in the second byte, that's the divisor the microcode will use.

(Of course you could add circuitry to verify that the number is 10, but then the implementation is no longer simple.)

Intel could have documented the full behavior, but that creates several problems. First, Intel would be stuck supporting the full behavior into the future. Second, there are corner cases to deal with, such as divide-by-zero. Third, testing the chip would become harder because all these cases would need to be tested. Fourth, the documentation would become long and confusing. It's not surprising that Intel left the full behavior undocumented.

AAD: ASCII Adjust before Division

The AAD instruction is analogous to AAM but used for BCD division.

In this case, you want to divide a two-digit BCD number by something, where the BCD digits are in AH and AL.

The AAD instruction converts the two-digit BCD number to binary by computing AH×10+AL, before you perform

the division.

The microcode for AAD is shown below. The microcode sets up the registers, calls the multiplication micro-subroutine

CORX (Core Times), and

then puts the results in AH and AL.

In more detail, the multiplier comes from the instruction prefetch queue Q.

The CORX routine multiples tmpC by tmpB, putting the result in tmpA/tmpC.

Then the microcode adds the low BCD digit (AL) to the product (tmpB + tmpC), putting the sum (Σ) into AL,

clearing AH and setting the status flags F appropriately.

One interesting thing is that the second-last micro-instruction jumps to AAEND, which is the last

micro-instruction of the AAM microcode above.

By reusing the micro-instruction from AAM, the microcode is one micro-instruction shorter, but

the jump adds one cycle to the execution time.

(The CORX routine is used for integer multiplication; I discuss the internals in this post.)

Q → tmpC AAD: Get byte from prefetch queue. AH → tmpB CALL CORX Call CORX AL → tmpB ADD tmpC Set ALU for ADD ZERO → AH JMP AAEND Zero AH, jump to AAEND i ... Σ → AL RNI F AAEND: Sum to AL, done.

As with AAM, the constant 10 is provided in the second byte of the instruction.

The microcode accepts any value here, but values other than 10 are undocumented.

8C, 8E: MOV sr

The opcodes 8C and 8E perform a MOV register to or from the specified segment register, using the register specification

field in the ModR/M byte.

There are four segment registers and three selection bits, so an invalid segment register can be specified.

However, the hardware that decodes the register number ignores instruction bit 5 for a segment register. Thus,

specifying a segment register 4 to 7 is the same as specifying a segment register 0 to 3.

For more details, see my article on 8086 register codes.

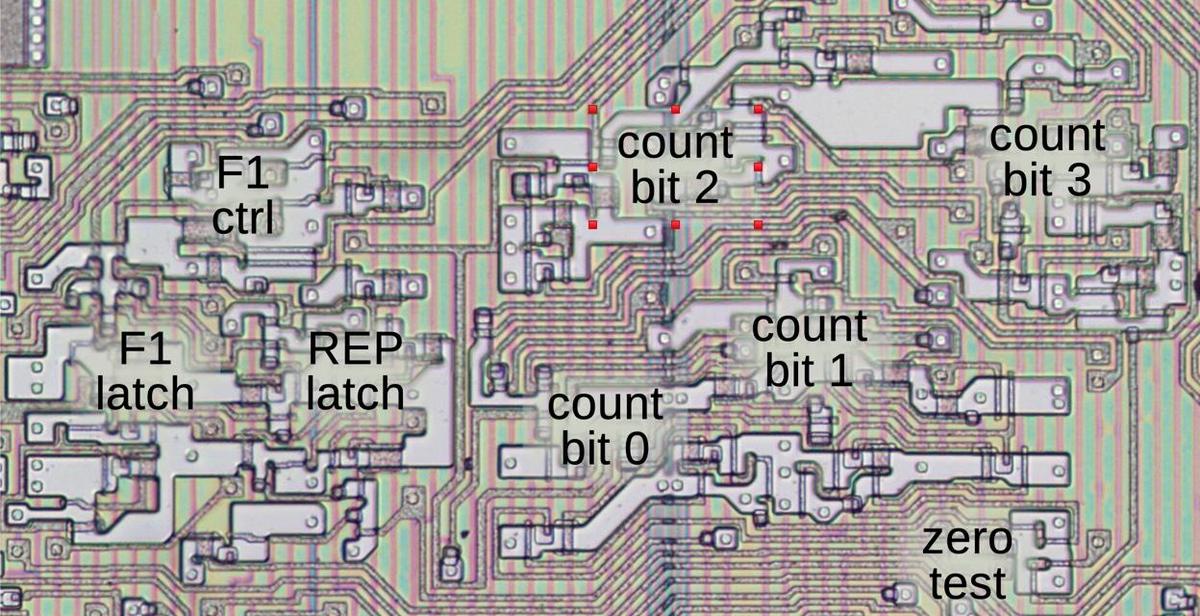

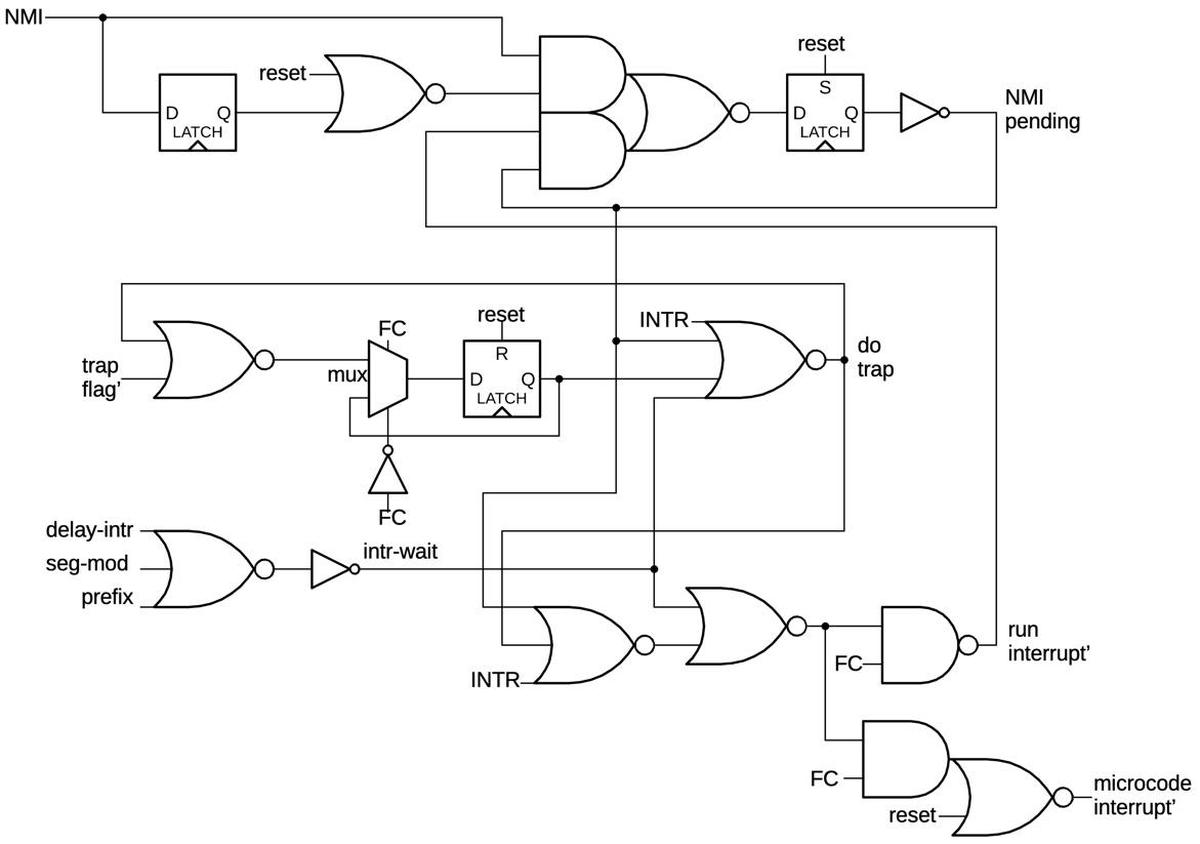

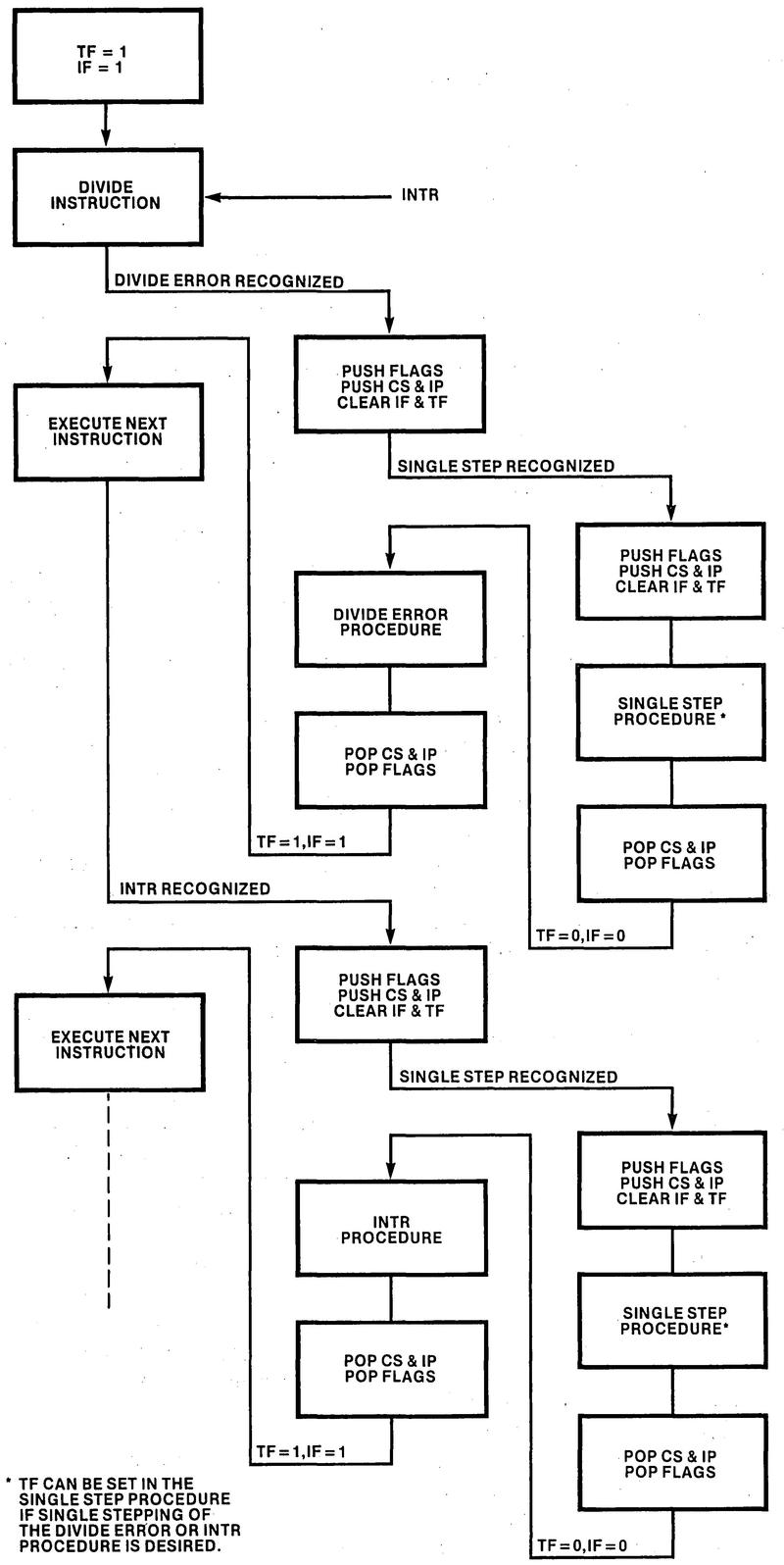

Unexpected REP prefix

REP IMUL / IDIV

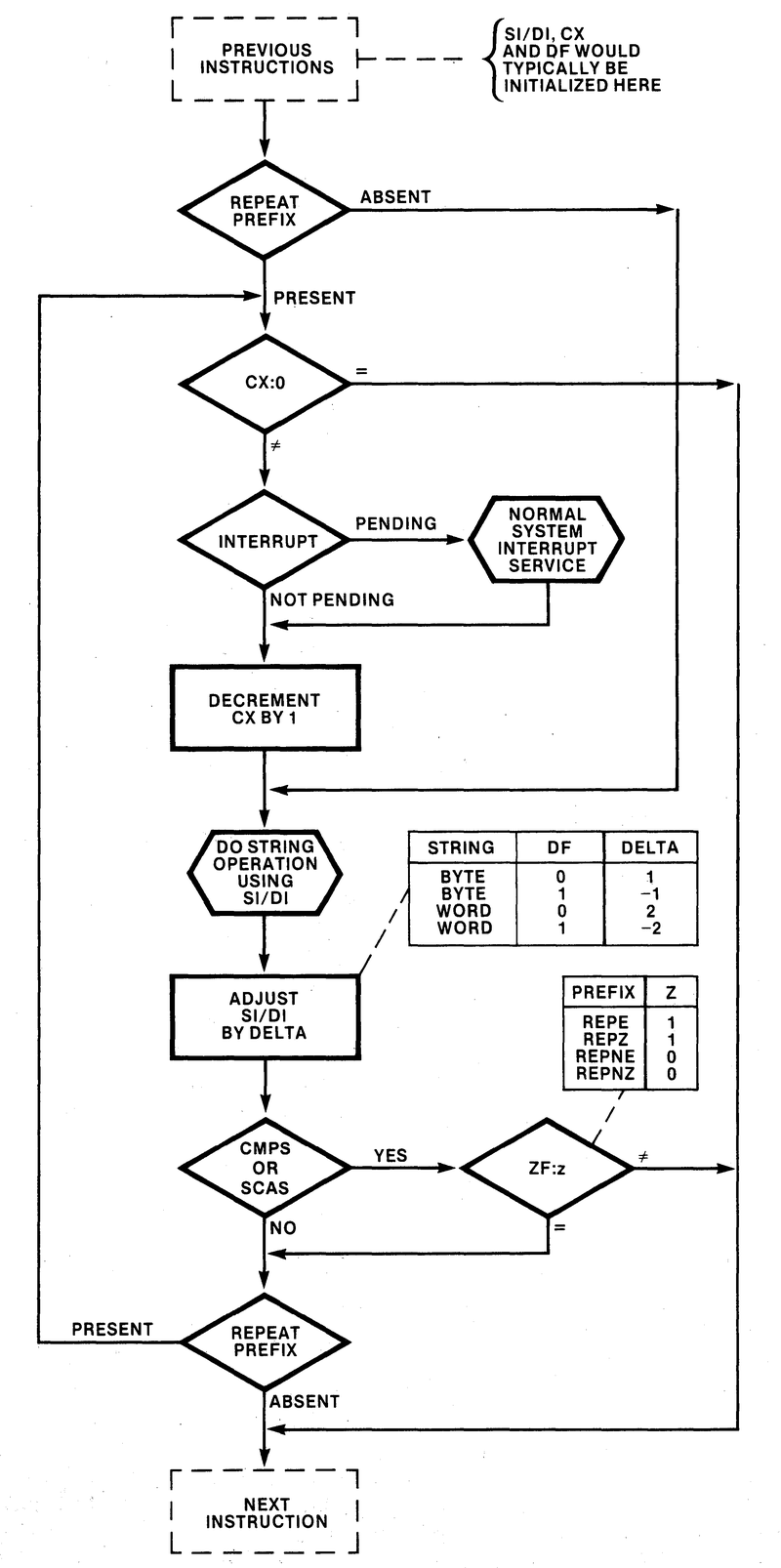

The REP prefix is used with string operations to cause the operation to be repeated across a block of memory.

However, if you use this prefix with an IMUL or IDIV instruction, it has the unexpected behavior

of negating the product or the quotient (source).

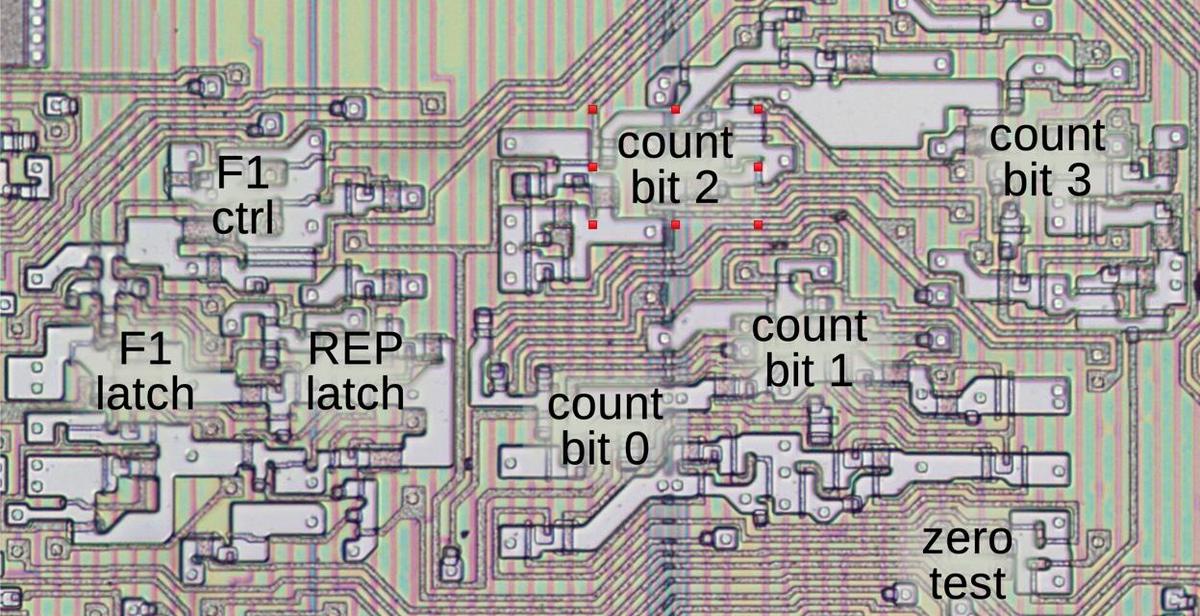

The reason for this behavior is that the string operations use an internal flag called F1 to indicate that a REP

prefix has been applied.

The multiply and divide code reuses this flag to track the sign of the input values, toggling F1 for each negative value.

If F1 is set, the value at the end is negated. (This handles "two negatives make a positive.")

The consequence is that the REP prefix puts the flag in the 1 state when the multiply/divide starts, so the computed sign

will be wrong at the end and the result is the negative of the expected result.

The microcode is fairly complex, so I won't show it here; I explain it in detail in this blog post.

REP RET

Wikipedia lists

REP RET (i.e. RET with a REP prefix) as a way to implement a two-byte return instruction.

This is kind of trivial; the RET microcode (like almost every instruction) doesn't use the F1 internal flag,

so the REP prefix has no effect.

REPNZ MOVS/STOS

Wikipedia mentions that

the use of the REPNZ prefix (as opposed to REPZ) is undefined with string operations other than CMPS/SCAS.

An internal flag called F1Z distinguishes between the REPZ and REPNZ prefixes.

This flag is only used by CMPS/SCAS. Since the other string instructions ignore this flag, they will ignore the

difference between REPZ and REPNZ.

I wrote about string operations in more detail in this post.

Using a register instead of memory.

Some instructions are documented as requiring a memory operand. However, the ModR/M byte can specify a register. The behavior in these cases can be highly unusual, providing access to hidden registers. Examining the microcode shows how this happens.

LEA reg

Many instructions have a ModR/M byte that indicates the memory address that the instruction should use, perhaps through

a complicated addressing mode.

The LEA (Load Effective Address) instruction is different: it doesn't access the memory location but returns the address itself.

The undocumented part is that the ModR/M byte can specify a register instead of a memory location. In that case,

what does the LEA instruction do? Obviously it can't return the address of a register, but it needs to return something.

The behavior of LEA is explained by how the 8086 handles the ModR/M byte.

Before running the microcode corresponding to the instruction, the microcode engine calls a short micro-subroutine

for the particular addressing mode.

This micro-subroutine puts the desired memory address (the effective address) into the tmpA register.

The effective address is copied to the IND (Indirect) register and the value is loaded from memory if needed.

On the other hand, if the ModR/M byte specified a register instead of memory, no micro-subroutine is called.

(I explain ModR/M handling in more detail in this article.)

The microcode for LEA itself is just one line. It stores the effective address in the IND register into the specified destination register, indicated by N.

This assumes that the appropriate ModR/M micro-subroutine was called before this code, putting the effective address into IND.

IND → N RNI LEA: store IND register in destination, done

But if a register was specified instead of a memory location, no ModR/M micro-subroutine gets called.

Instead, the LEA instruction will return whatever value was left

in IND from before, typically the previous memory location that was accessed.

Thus, LEA can be used to read the value of the IND register, which is normally hidden from the programmer.

LDS reg, LES reg

The LDS and LES instructions load a far pointer from memory into the specified segment register and general-purpose register.

The microcode below assumes that the appropriate ModR/M micro-subroutine has set up IND and read the first value into OPR.

The microcode updates the destination register, increments IND by 2, reads the next value, and updates DS.

(The microcode for LES is a copy of this, but updates ES.)

OPR → N LDS: Copy OPR to dest register IND → tmpC INC2 tmpC Set up incrementing IND by 2 Σ → IND R DS,P0 Update IND, read next location OPR → DS RNI Update DS

If the LDS instruction specifies a register instead of memory, a micro-subroutine will not be called, so IND and OPR

will have values from a previous instruction.

OPR will be stored in the destination register, while the DS value will be read from the address IND+2.

Thus, these instructions provide a mechanism to access the hidden OPR register.

JMP FAR rm

The JMP FAR rm instruction normally jumps to the far address stored in memory at the location indicated by the ModR/M byte.

(That is, the ModR/M byte indicates where the new PC and CS values are stored.)

But, as with LEA, the behavior is undocumented if the ModR/M byte specifies a register, since a register doesn't hold

a four-byte value.

The microcode explains what happens.

As with LEA, the code expects a micro-subroutine to put the address into the IND register.

In this case, the micro-subroutine also loads the value at that address (i.e. the destination PC) into tmpB.

The microcode increments IND by 2 to point to the CS word in memory and reads that into CS.

Meanwhile, it updates the PC with tmpB.

It suspends prefetching and flushes the queue, so instruction fetching will restart at the new address.

IND → tmpC INC2 tmpC JMP FAR rm: set up to add 2 to IND Σ → IND SUSP Update IND, suspend prefetching tmpB → PC R DS,P0 Update PC with tmpB. Read new CS from specified address OPR → CS FLUSH RNI Update CS, flush queue, done

If you specify a register instead of memory, the micro-subroutine won't get called.

Instead, the program counter will be loaded with whatever value was in tmpB and the CS segment register will

be loaded from the memory location two bytes after the location that IND was referencing.

Thus, this undocumented use of the instruction gives access to the otherwise-hidden tmpB register.

The end of undocumented instructions

Microprocessor manufacturers soon realized that undocumented instructions were a problem, since programmers find them and often use them. This creates an issue for future processors, or even revisions of the current processor: if you eliminate an undocumented instruction, previously-working code that used the instruction will break, and it will seem like the new processor is faulty.

The solution was for processors to detect undocumented instructions and prevent them from executing. By the early 1980s, processors had enough transistors (thanks to Moore's law) that they could include the circuitry to block unsupported instructions. In particular, the 80186/80188 and the 80286 generated a trap of type 6 when an unused opcode was executed, blocking use of the instruction.9 This trap is also known as #UD (Undefined instruction trap).10

Conclusions

The 8086, like many early microprocessors, has undocumented instructions but no traps to stop them from executing.11

For the 8086, these fall into several categories.

Many undocumented instructions simply mirror existing instructions.

Some instructions are implemented but not documented for one reason or another, such as SALC and POP CS.

Other instructions can be used outside their normal range, such as AAM and AAD.

Some instructions are intended to work only with a memory address, so specifying a register can have

strange effects such as revealing the values of the hidden IND and OPR registers.

Keep in mind that my analysis is based on transistor-level simulation and examining the microcode; I haven't verified the behavior on a physical 8086 processor. Please let me know if you see any errors in my analysis or undocumented instructions that I have overlooked. Also note that the behavior could change between different versions of the 8086; in particular, some versions by different manufacturers (such as the NEC V20 and V30) are known to be different.

I plan to write more about the 8086, so follow me on Twitter @kenshirriff or RSS for updates. I've also started experimenting with Mastodon recently as @kenshirriff@oldbytes.space and Bluesky as @righto.com so you can follow me there too.

Notes and references

-

The 6502 processor, for instance, has illegal instructions with various effects, including causing the processor to hang. The article How MOS 6502 illegal opcodes really work describes in detail how the instruction decoding results in various illegal opcodes. Some of these opcodes put the internal bus into a floating state, so the behavior is electrically unpredictable. ↩

-

The 8086 used up almost all the single-byte opcodes, which made it difficult to extend the instruction set. Most of the new instructions for the 386 or later are multi-byte opcodes, either using

0Fas a prefix or reusing the earlier REP prefix (F3). Thus, the x86 instruction set is less efficient than it could be, since many single-byte opcodes were "wasted" on hardly-used instructions such as BCD arithmetic, forcing newer instructions to be multi-byte. ↩ -

For details on the "magic instruction" hidden in the 8086 microcode, see NEC v. Intel: Will Hardware Be Drawn into the Black Hole of Copyright Editors page 49. I haven't found anything stating that

SALCwas the hidden instruction, but this is the only undocumented instruction that makes sense as something deliberately put into the microcode. The court case is complicated since NEC had a licensing agreement with Intel, so I'm skipping lots of details. See NEC v. Intel: Breaking new ground in the law of copyright for more. ↩ -

The microcode listings are based on Andrew Jenner's disassembly. I have made some modifications to (hopefully) make it easier to understand. ↩

-

Specifying the instruction through the ModR/M reg field may seem a bit random, but there's a reason for this. A typical instruction such as

ADDhas two arguments specified by the ModR/M byte. But other instructions such as shift instructions orNOTonly take one argument. For these instructions, the ModR/Mregfield would be wasted if it specified a register. Thus, using theregfield to specify instructions that only use one argument makes the instruction set more efficient. ↩ -

Note that "normal" ALU operations are specified by bits 5-3 of the instruction; in order these are

ADD,OR,ADC,SBB,AND,SUB,XOR, andCMP. These are exactly the same ALU operations that the "Immed" group performs, specified by bits 5-3 of the second byte. This illustrates how the same operation selection mechanism (theXregister) is used in both cases. Bit 6 of the instruction switches between the set of arithmetic/logic instructions and the set of shift/rotate instructions. ↩ -

As far as I can tell, SETMO isn't used by the microcode. Thus, I think that SETMO wasn't deliberately implemented in the ALU, but is a consequence of how the ALU's control logic is implemented. That is, all the even entries are left shifts and the odd entries are right shifts, so operation 6 activates the left-shift circuitry. But it doesn't match a specific left shift operation, so the ALU doesn't get configured for a "real" left shift. In other words, the behavior of this instruction is due to how the ALU handles a case that it wasn't specifically designed to handle.

This function is implemented in the ALU somewhat similar to a shift left. However, instead of passing each input bit to the left, the bit from the right is passed to the left. That is, the input to bit 0 is shifted left to all of the bits of the result. By setting this bit to 1, all bits of the result are set, yielding the minus 1 result. ↩

-

This footnote provides some references for the "Immed" opcodes. The 8086 datasheet has an opcode map showing opcodes

80through83as valid. However, in the listings of individual instructions it only shows80and81for logical instructions (i.e. bit 1 must be 0), while it shows80-83for arithmetic instructions. The modern Intel 64 and IA-32 Architectures Software Developer's Manual is also contradictory. Looking at the instruction reference forAND(Vol2A3-78), for instance, shows opcodes80,81, and83, explicitly labeling83as sign-extended. But the opcode map (Table A-2 Vol2DA-7) shows80-83as defined except for82in64-bit mode. The instruction bit diagram (Table B-13Vol2DB-7) shows80-83valid for the arithmetic and logical instructions. ↩ -

The 80286 was more thorough about detecting undefined opcodes than the 80186, even taking into account the differences in instruction set. The 80186 generates a trap when

0F,63-67,F1, orFFFFis executed. The 80286 generates invalid opcode exception number 6 (#UD) on any undefined opcode, handling the following cases:- The first byte of an instruction is completely invalid (e.g., 64H).

- The first byte indicates a 2-byte opcode and the second byte is invalid (e.g., 0F followed by 0FFH).

- An invalid register is used with an otherwise valid opcode (e.g., MOV CS,AX).

- An invalid opcode extension is given in the REG field of the ModR/M byte (e.g., 0F6H /1).

- A register operand is given in an instruction that requires a memory operand (e.g., LGDT AX).

-

In modern x86 processors, most undocumented instructions cause faults. However, there are still a few undocumented instructions that don't fault. These may be for internal use or corner cases of documented instructions. For details, see Breaking the x86 Instruction Set, a video from Black Hat 2017. ↩

-

Several sources have discussed undocumented 8086 opcodes before. The article Undocumented 8086 Opcodes describes undocumented opcodes in detail. Wikipedia has a list of undocumented x86 instructions. The book Undocumented PC discusses undocumented instructions in the 8086 and later processors. This StackExchange Retrocomputing post describes undocumented instructions. These Hacker News comments discuss some undocumented instructions. There are other sources with more myth than fact, claiming that the 8086 treats undocumented instructions as NOPs, for instance. ↩

Subject: Reverse-engineering the 8086 processor's address and data pin circuits

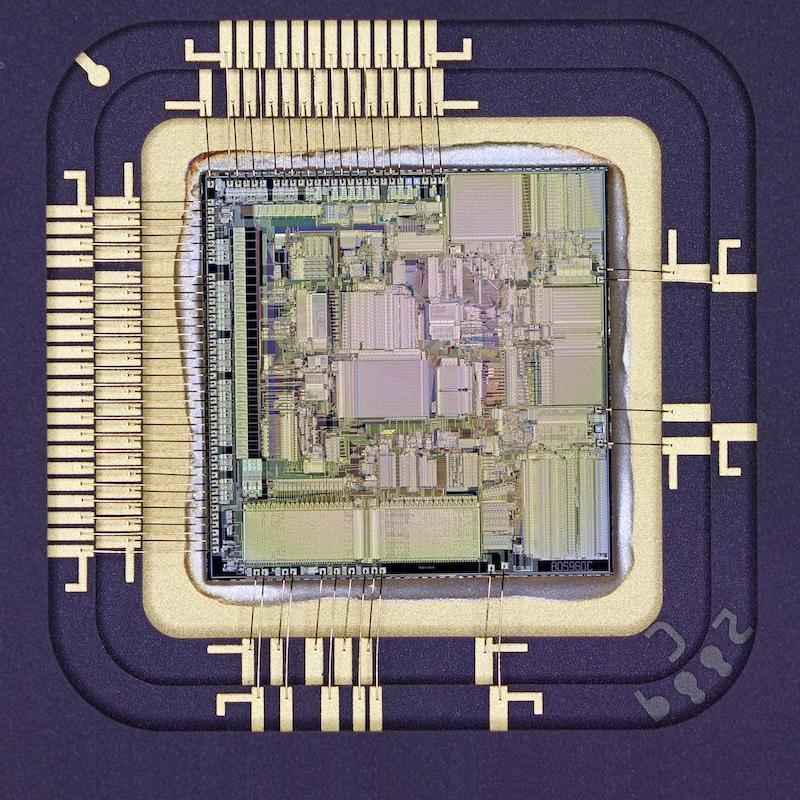

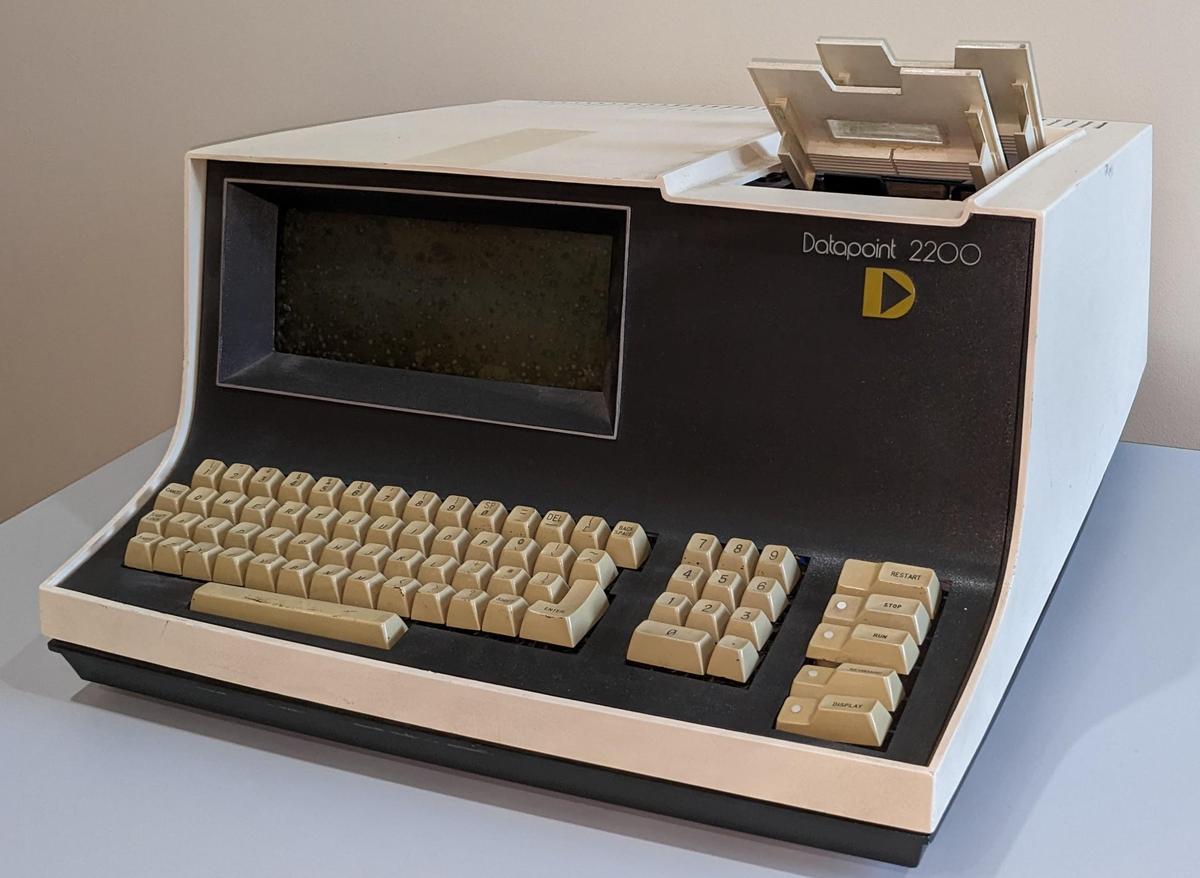

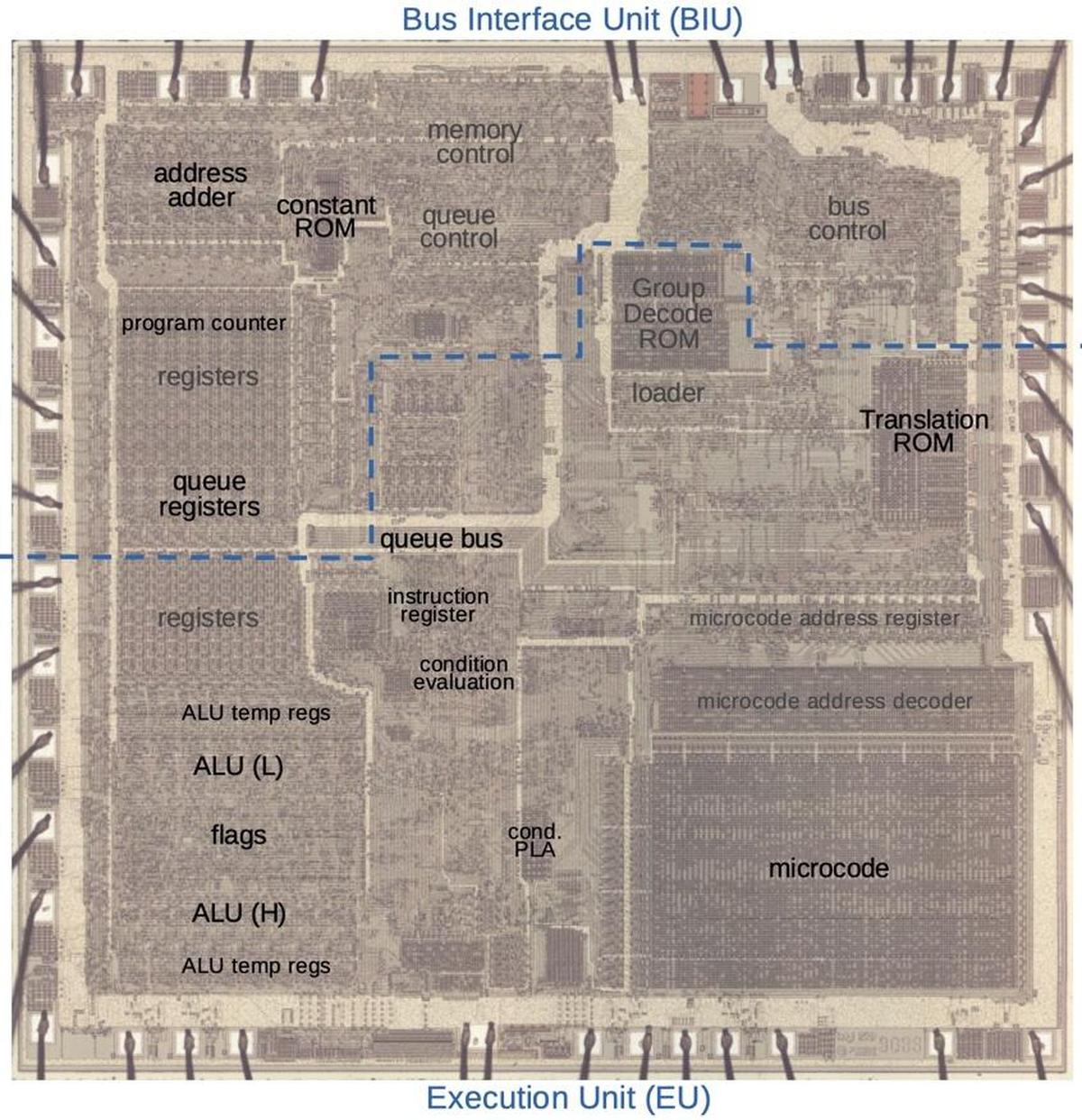

The Intel 8086 microprocessor (1978) started the x86 architecture that continues to this day. In this blog post, I'm focusing on a small part of the chip: the address and data pins that connect the chip to external memory and I/O devices. In many processors, this circuitry is straightforward, but it is complicated in the 8086 for two reasons. First, Intel decided to package the 8086 as a 40-pin DIP, which didn't provide enough pins for all the functionality. Instead, the 8086 multiplexes address, data, and status. In other words, a pin can have multiple roles, providing an address bit at one time and a data bit at another time.

The second complication is that the 8086 has a 20-bit address space (due to its infamous segment registers), while the data bus is 16 bits wide. As will be seen, the "extra" four address bits have more impact than you might expect. To summarize, 16 pins, called AD0-AD15, provide 16 bits of address and data. The four remaining address pins (A16-A19) are multiplexed for use as status pins, providing information about what the processor is doing for use by other parts of the system. You might expect that the 8086 would thus have two types of pin circuits, but it turns out that there are four distinct circuits, which I will discuss below.

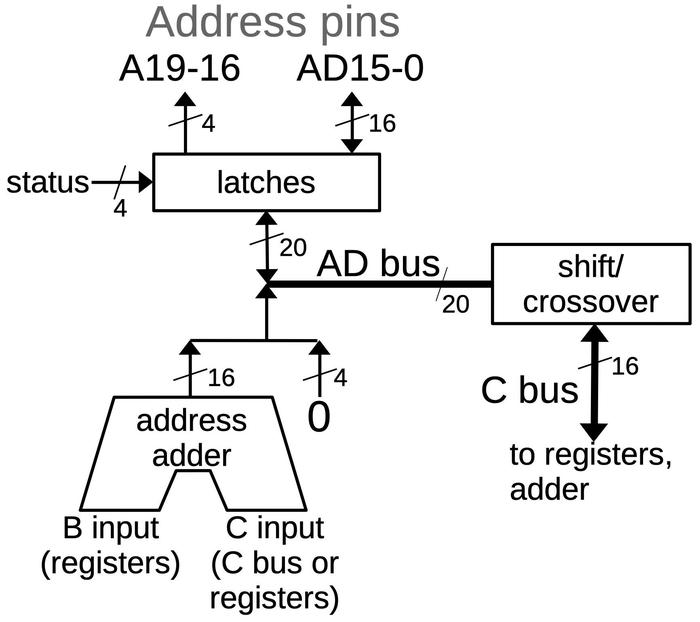

The microscope image above shows the silicon die of the 8086. In this image, the metal layer on top of the chip is visible, while the silicon and polysilicon underneath are obscured. The square pads around the edge of the die are connected by tiny bond wires to the chip's 40 external pins. The 20 address pins are labeled: Pins AD0 through AD15 function as address and data pins. Pins A16 through A19 function as address pins and status pins.1 The circuitry that controls the pins is highlighted in red. Two internal busses are important for this discussion: the 20-bit AD bus (green) connects the AD pins to the rest of the CPU, while the 16-bit C bus (blue) communicates with the registers. These buses are connected through a circuit that can swap the byte order or shift the value. (The lines on the diagram are simplified; the real wiring twists and turns to fit the layout. Moreover, the C bus (blue) has its bits spread across the width of the register file.)

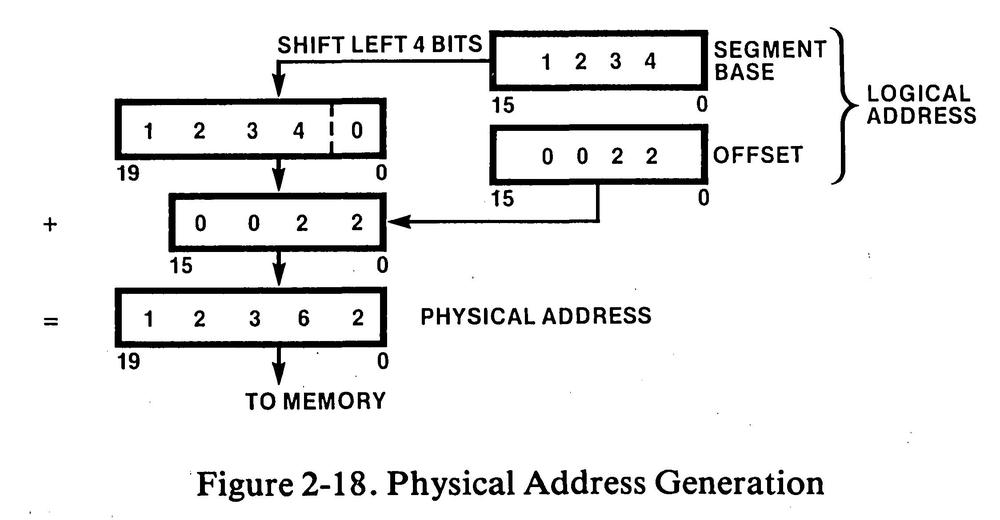

Segment addressing in the 8086

One goal of the 8086 design was to maintain backward compatibility with the earlier 8080 processor.2 This had a major impact on the 8086's memory design, resulting in the much-hated segment registers. The 8080 (like most of the 8-bit processors of the early 1970s) had a 16-bit address space, able to access 64K (65,536 bytes) of memory, which was plenty at the time. But due to the exponential growth in memory capacity described by Moore's Law, it was clear that the 8086 needed to support much more. Intel decided on a 1-megabyte address space, requiring 20 address bits. But Intel wanted to keep the 16-bit memory addresses used by the 8080.

The solution was to break memory into segments. Each segment was 64K long, so a 16-bit offset was sufficient to access memory in a segment. The segments were allocated in a 1-megabyte address space, with the result that you could access a megabyte of memory, but only in 64K chunks.3 Segment addresses were also 16 bits, but were shifted left by 4 bits (multiplied by 16) to support the 20-bit address space.

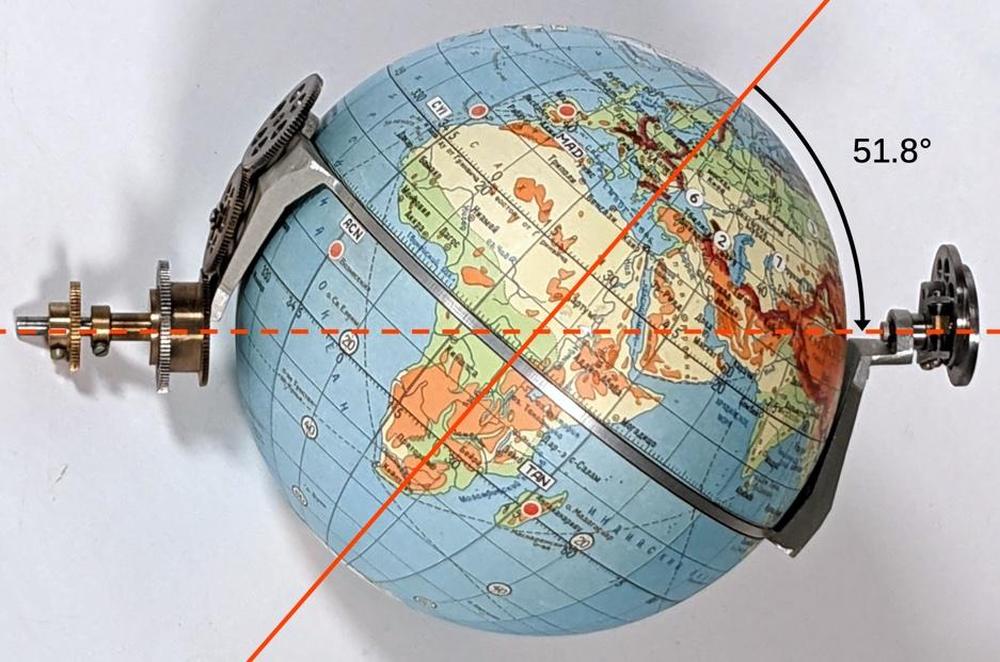

Thus, every memory access in the 8086 required a computation of the physical address. The diagram below illustrates this process: the logical address consists of the segment base address and the offset within the segment. The 16-bit segment register was shifted 4 bits and added to the 16-bit offset to yield the 20-bit physical memory address.

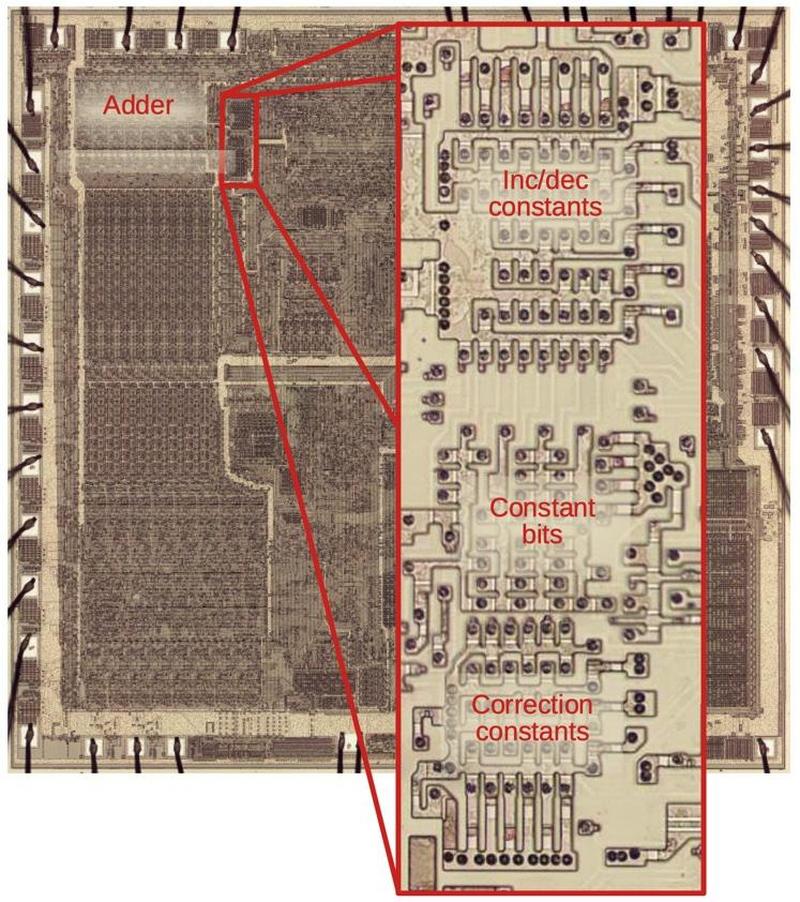

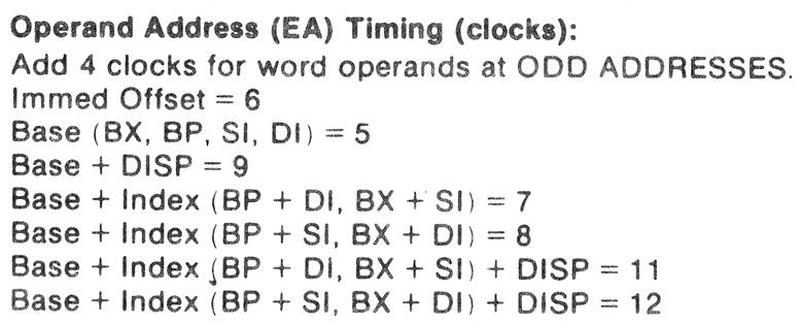

This address computation was not performed by the regular ALU (Arithmetic/Logic Unit), but by a separate adder that was devoted to address computation. The address adder is visible in the upper-left corner of the die photo. I will discuss the address adder in more detail below.

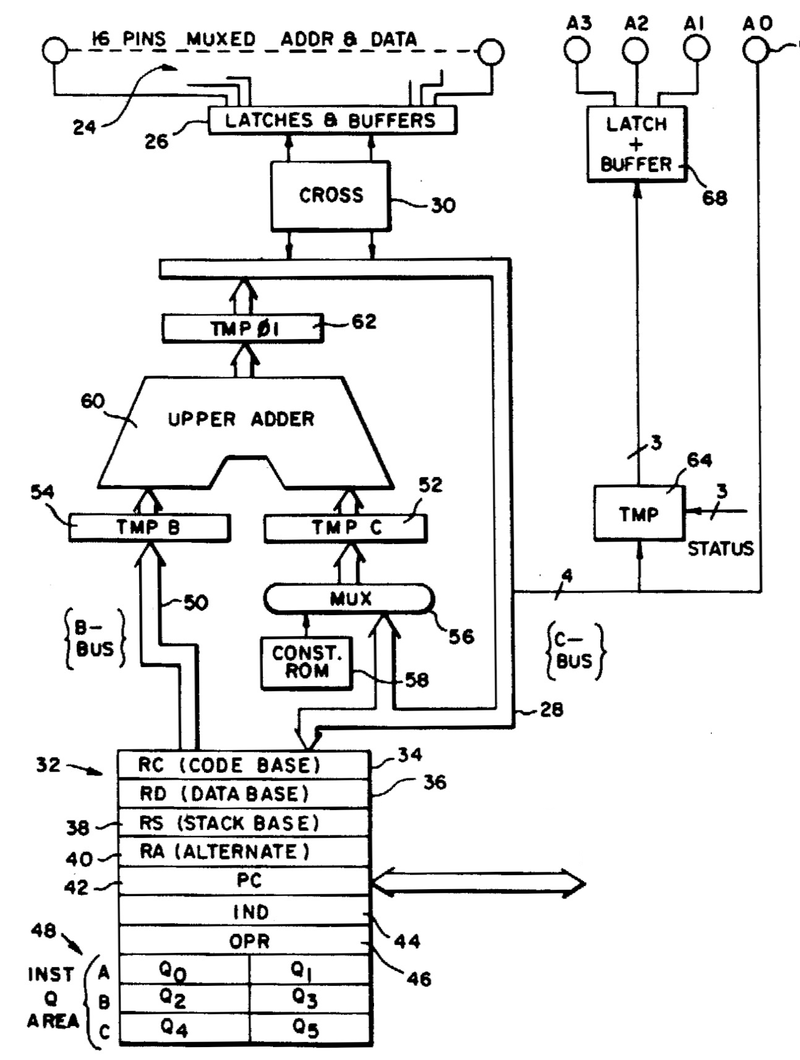

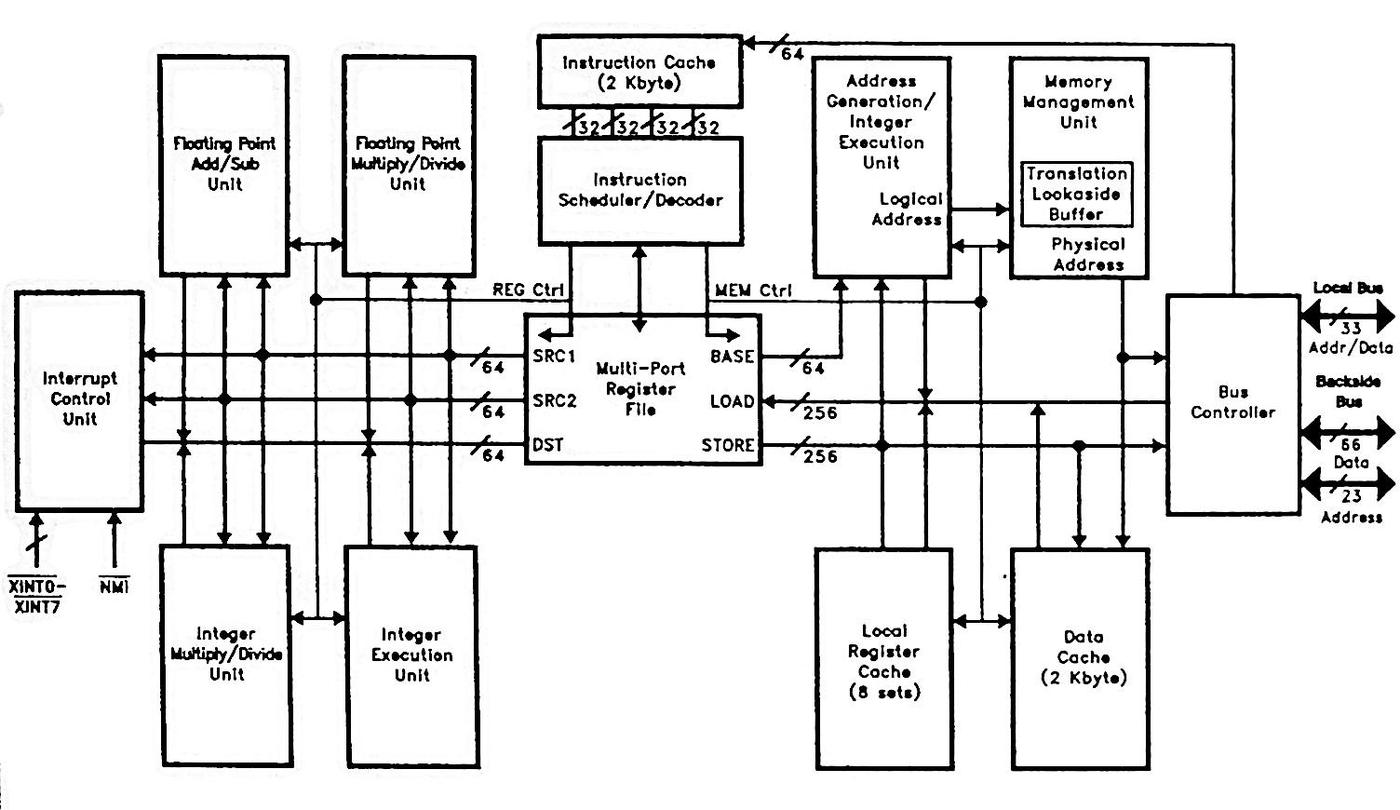

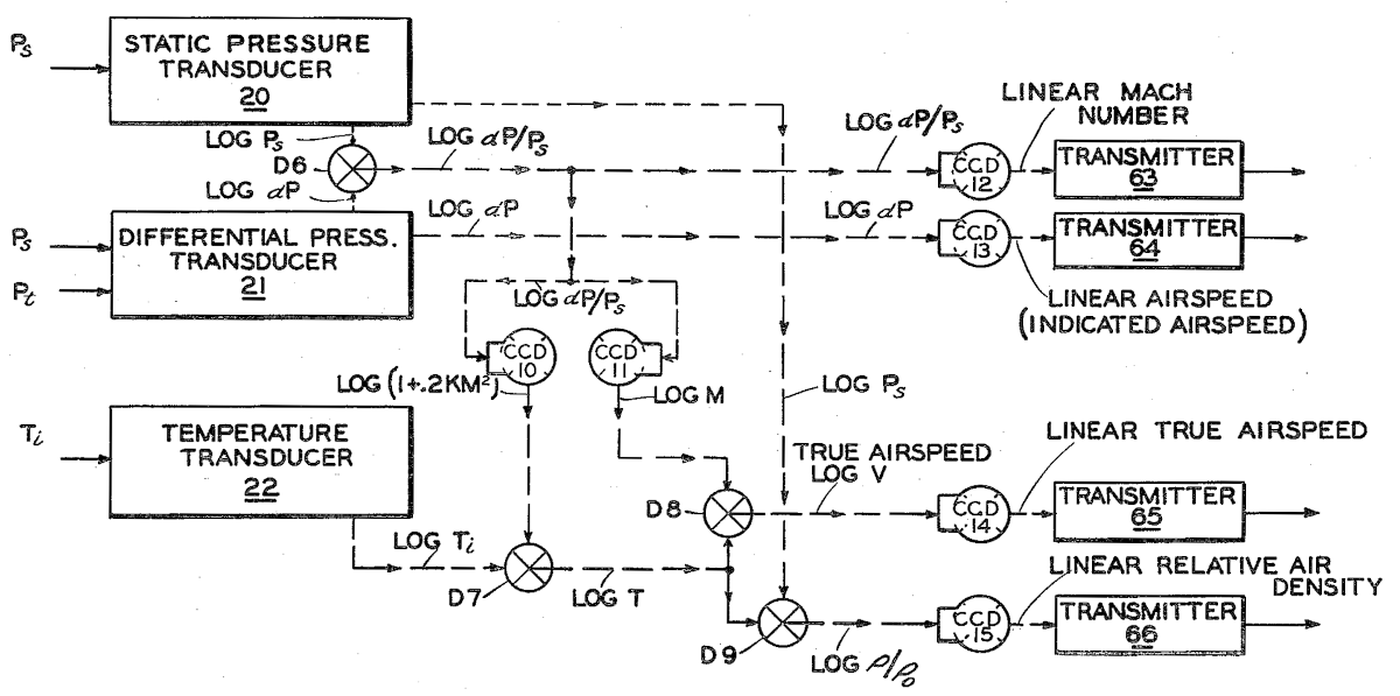

The AD bus and the C Bus

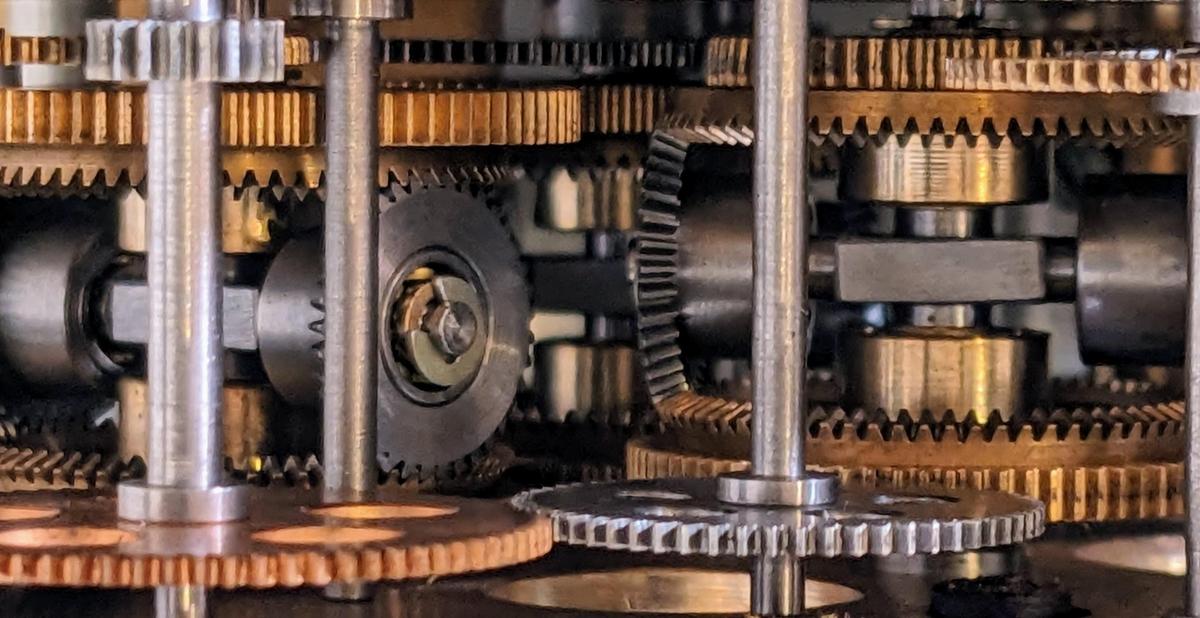

The 8086 has multiple internal buses to move bits internally, but the relevant ones are the AD bus and the C bus. The AD bus is a 20-bit bus that connects the 20 address/data pins to the internal circuitry.4 A 16-bit bus called the C bus provides the connection between the AD bus, the address adder and some of the registers.5 The diagram below shows the connections. The AD bus can be connected to the 20 address pins through latches. The low 16 pins can also be used for data input, while the upper 4 pins can also be used for status output. The address adder performs the 16-bit addition necessary for segment arithmetic. Its output is shifted left by four bits (i.e. it has four 0 bits appended), producing the 20-bit result. The inputs to the adder are provided by registers, a constant ROM that holds small constants such as +1 or -2, or the C bus.

The shift/crossover circuit provides the interface between these two buses, handling the 20-bit to 16-bit conversion. The busses can be connected in three ways: direct, crossover, or shifted.6 The direct mode connects the 16 bits of the C bus to the lower 16 bits of the address/data pins. This is the standard mode for transferring data between the 8086's internal circuitry and the data pins. The crossover mode performs the same connection but swaps the bytes. This is typically used for unaligned memory accesses, where the low memory byte corresponds to the high register byte, or vice versa. The shifted mode shifts the 20-bit AD bus value four positions to the right. In this mode, the 16-bit output from the address adder goes to the 16-bit C bus. (The shift is necessary to counteract the 4-bit shift applied to the address adder's output.) Control circuitry selects the right operation for the shift/crossover circuit at the right time.7

Two of the registers are invisible to the programmer but play an important role in memory accesses.

The IND (Indirect) register specifies the memory address; it holds the 16-bit memory offset in a segment.

The OPR (Operand) register holds the data value.9

The IND and OPR registers are not accessed directly by the programmer; the microcode for a machine instruction moves the appropriate

values to these registers prior to the write.

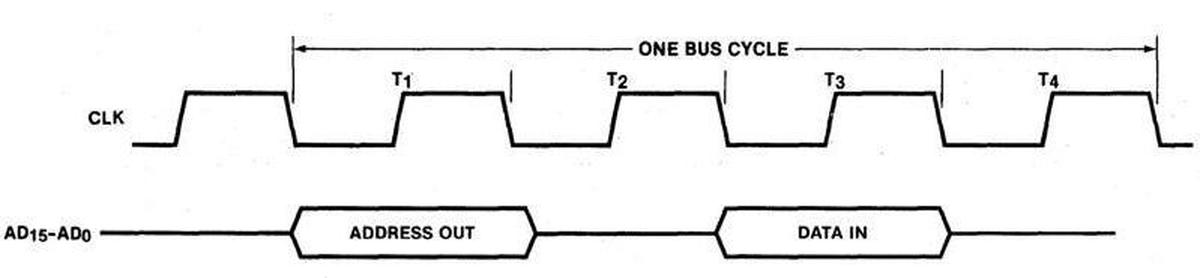

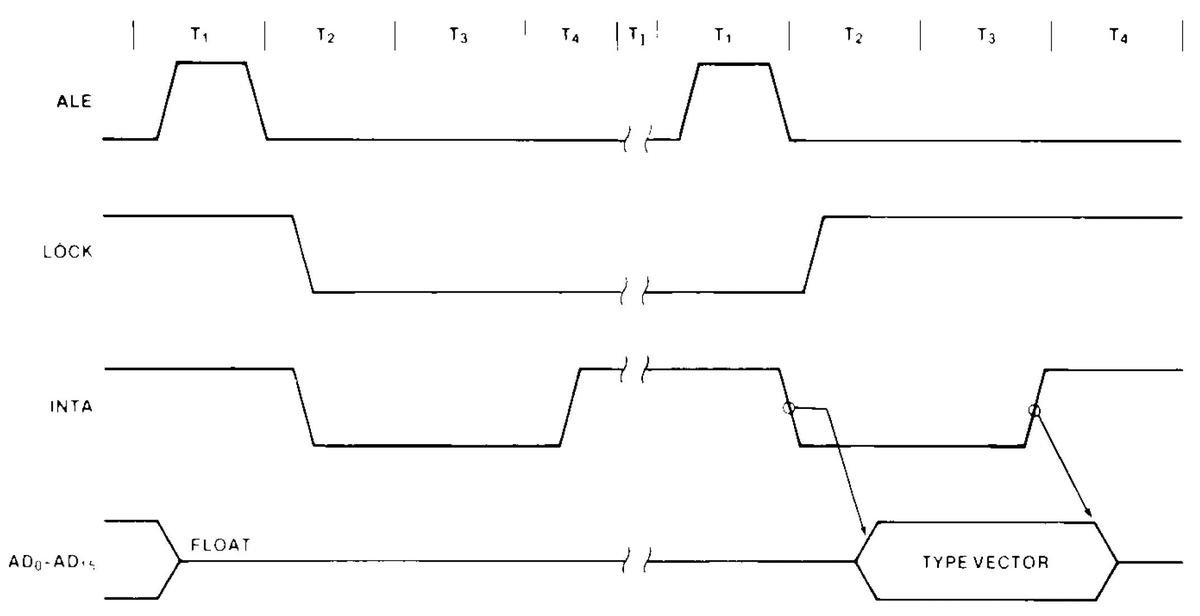

Overview of a write cycle

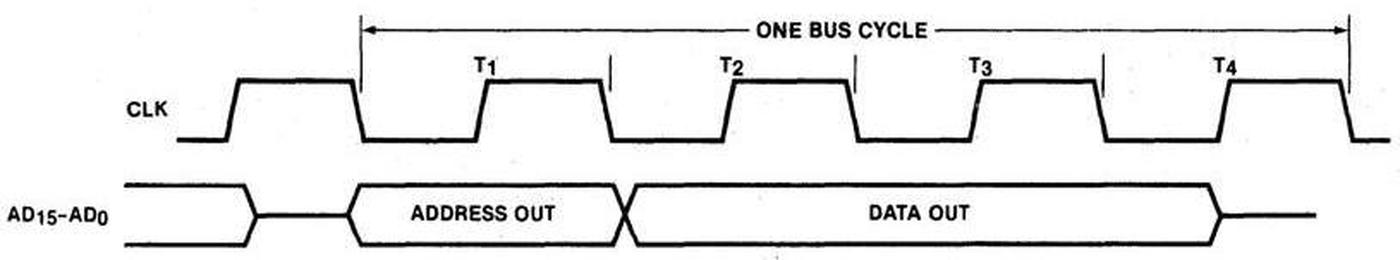

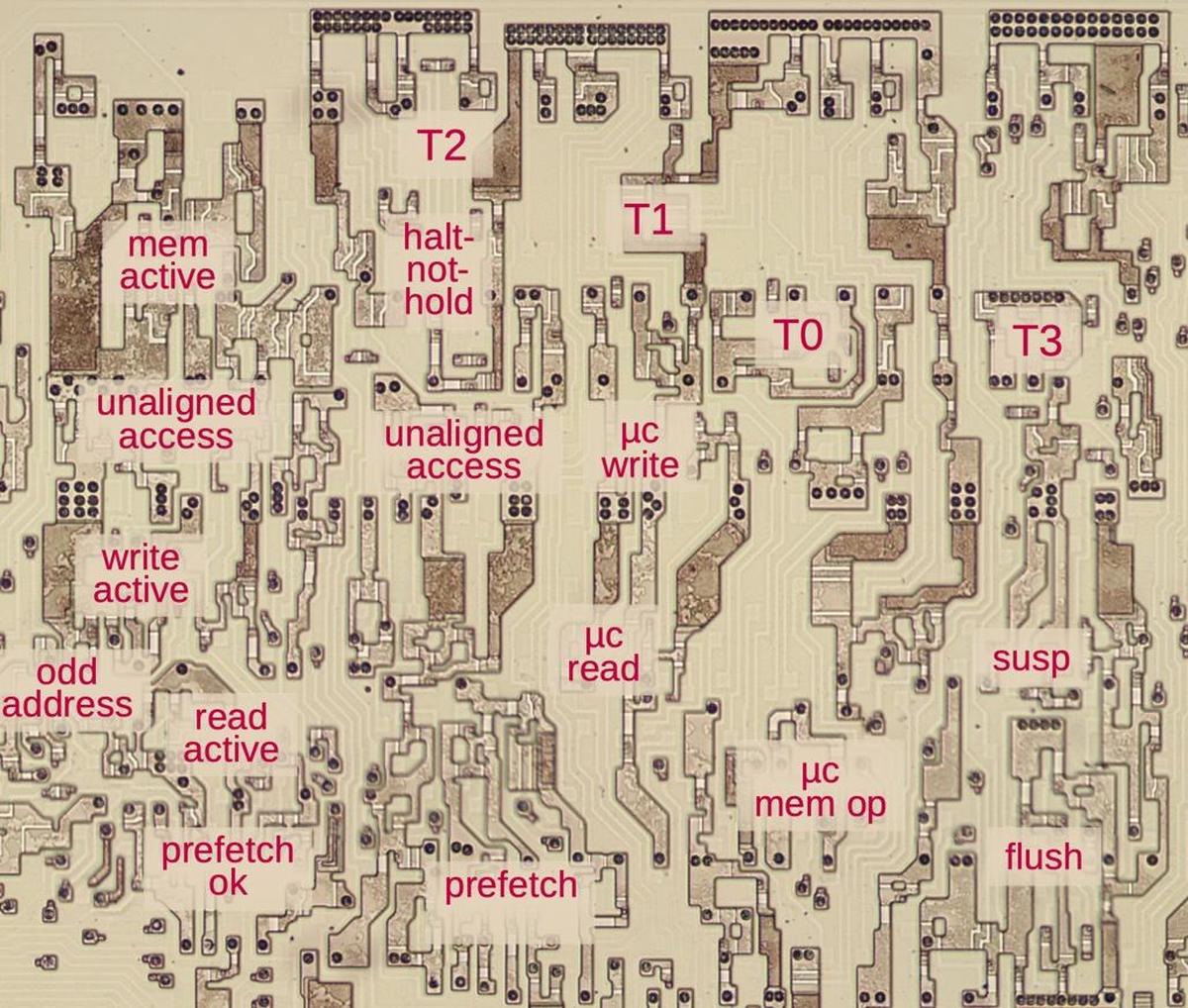

I hesitate to present a timing diagram, since I may scare off of my readers, but the 8086's communication is designed around a four-step bus cycle. The diagram below shows simplified timing for a write cycle, when the 8086 writes to memory or an I/O device.8 The external bus activity is organized as four states, each one clock cycle long: T1, T2, T3, T4. These T states are very important since they control what happens on the bus. During T1, the 8086 outputs the address on the pins. During the T2, T3, and T4 states, the 8086 outputs the data word on the pins. The important part for this discussion is that the pins are multiplexed depending on the T-state: the pins provide the address during T1 and data during T2 through T4.

There two undocumented T states that are important to the bus cycle. The physical address is computed in the two clock cycles before T1 so the address will be available in T1. I give these "invisible" T states the names TS (start) and T0.

The address adder

The operation of the address adder is a bit tricky since the 16-bit adder must generate a 20-bit physical address. The adder has two 16-bit inputs: the B input is connected to the upper registers via the B bus, while the C input is connected to the C bus. The segment register value is transferred over the B bus to the adder during the second half of the TS state (that is, two clock cycles before the bus cycle becomes externally visible during T1). Meanwhile, the address offset is transferred over the C bus to the adder, but the adder's C input shifts the value four bits to the right, discarding the four low bits. (As will be explained later, the pin driver circuits latch these bits.) The adder's output is shifted left four bits and transferred to the AD bus during the second half of T0. This produces the upper 16 bits of the 20-bit physical memory address. This value is latched into the address output flip-flops at the start of T1, putting the computed address on the pins. To summarize, the 20-bit address is generated by storing the 4 low-order bits during T0 and then the 16 high-order sum bits during T1.

The address adder is not needed for segment arithmetic during T1 and T2.

To improve performance, the 8086 uses the adder during this idle time to increment or decrement memory addresses.

For instance, after popping a word from the stack, the stack pointer needs to be incremented by 2.

The address adder can do this increment "for free" during T1 and T2, leaving the ALU available for other operations.10

Specifically, the adder updates the memory address in IND, incrementing it or decrementing it as appropriate.

First, the IND value is transferred over the B bus to the adder during the second half of T1.

Meanwhile, a constant (-3 to +2) is loaded from the Constant ROM and transferred to the adder's C input.

The output from the adder is transferred to the AD bus during the second half of T2.

As before, the output is shifted four bits to the left. However, the shift/crossover circuit between the AD bus and the C bus

is configured to shift four bits to the right, canceling the adder's shift.

The result is that the C bus gets the 16-bit sum from the adder, and this value is stored in the IND register.11

For more information on the implemenation of the address adder, see my previous blog post.

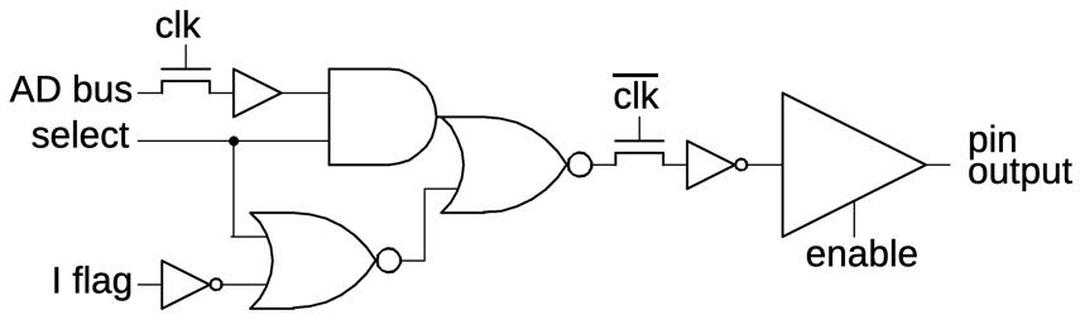

The pin driver circuit

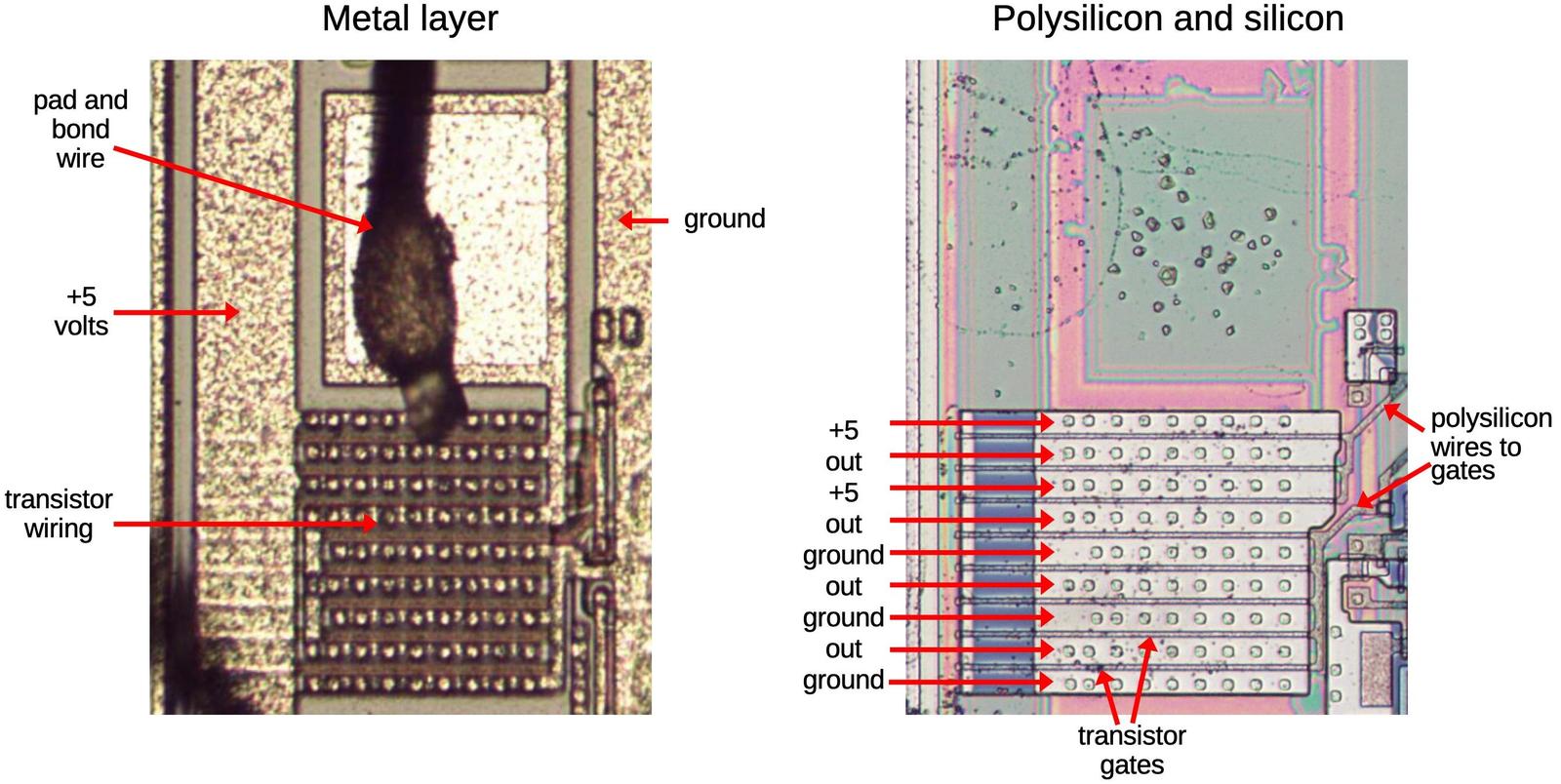

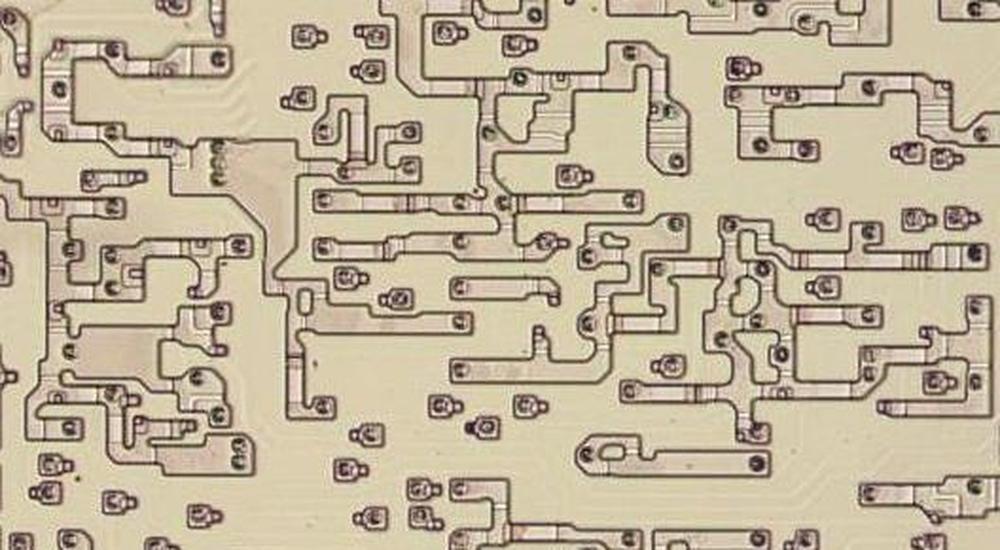

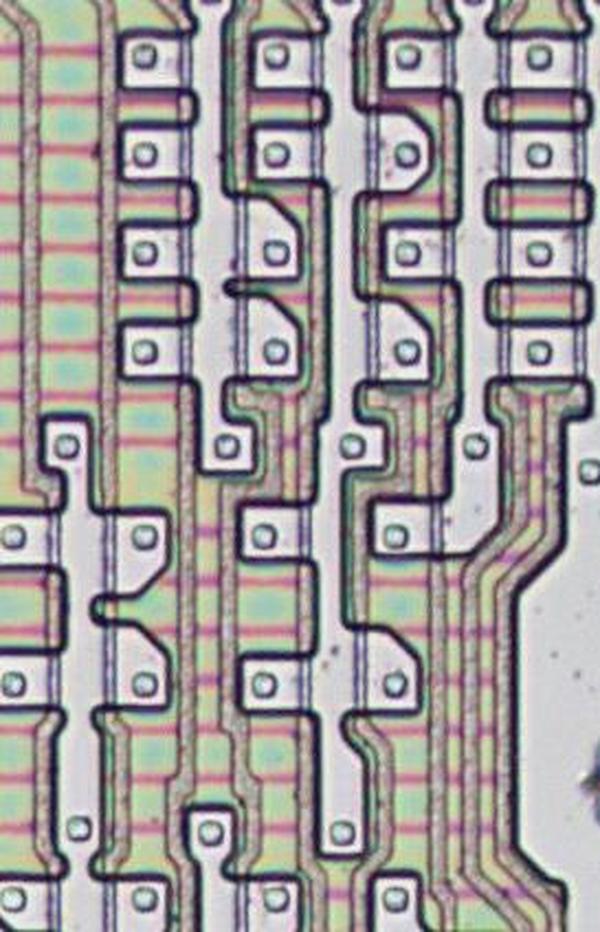

Now I'll dive down to the hardware implementation of an output pin. When the 8086 chip communicates with the outside world, it needs to provide relatively high currents. The tiny logic transistors can't provide enough current, so the chip needs to use large output transistors. To fit the large output transistors on the die, they are constructed of multiple wide transistors in parallel.12 Moreover, the drivers use a somewhat unusual "superbuffer" circuit with two transistors: one to pull the output high, and one to pull the output low.13

The diagram below shows the transistor structure for one of the output pins (AD10), consisting of three parallel transistors between the output and +5V, and five parallel transistors between the output and ground. The die photo on the left shows the metal layer on top of the die. This shows the power and ground wiring and the connections to the transistors. The photo on the right shows the die with the metal layer removed, showing the underlying silicon and the polysilicon wiring on top. A transistor gate is formed where a polysilicon wire crosses the doped silicon region. Combined, the +5V transistors are equivalent to about 60 typical transistors, while the ground transistors are equivalent to about 100 typical transistors. Thus, these transistors provide substantially more current to the output pin.

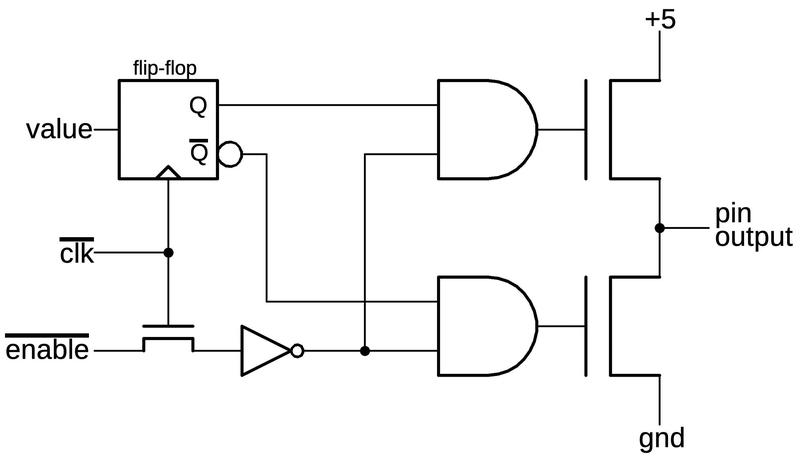

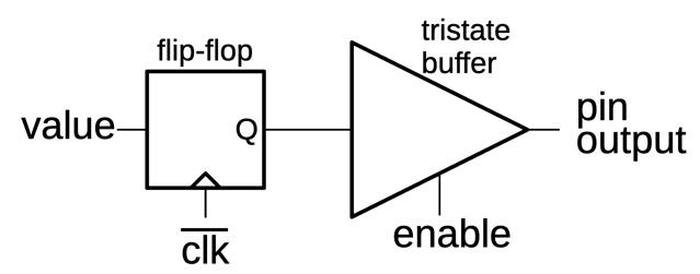

Tri-state output driver

The output circuit for an address pin uses a tri-state buffer, which allows the output to be disabled by putting it into a high-impedance "tri-state" configuration. In this state, the output is not pulled high or low but is left floating. This capability allows the pin to be used for data input. It also allows external devices to device can take control of the bus, for instance, to perform DMA (direct memory access).

The pin is driven by two large MOSFETs, one to pull the output high and one to pull it low. (As described earlier, each large MOSFET is physically multiple transistors in parallel, but I'll ignore that for now.) If both MOSFETs are off, the output floats, neither on nor off.

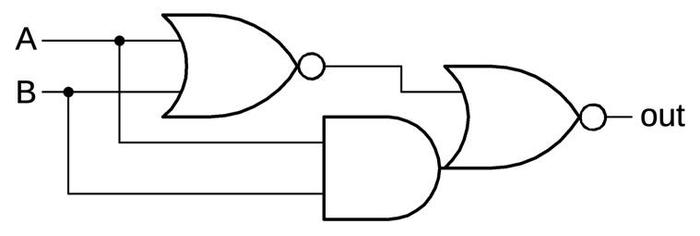

The tri-state output is implemented by driving the MOSFETs with two "superbuffer"15 AND gates.

If the enable input is low, both AND gates produce a low output and both output transistors are off.

On the other hand, if enable is high, one AND gate will be on and one will be off.

The desired output value is loaded into a flip-flop to hold it,14

and the flip-flop turns one of the output transistors on, driving the output pin high or low as appropriate.

(Conveniently, the flip-flop provides the data output Q and the inverted data output Q.)

Generally, the address pin outputs are enabled for T1-T4 of a write but only during T1 for a read.16

In the remainder of the discussion, I'll use the tri-state buffer symbol below, rather than showing the implementation of the buffer.

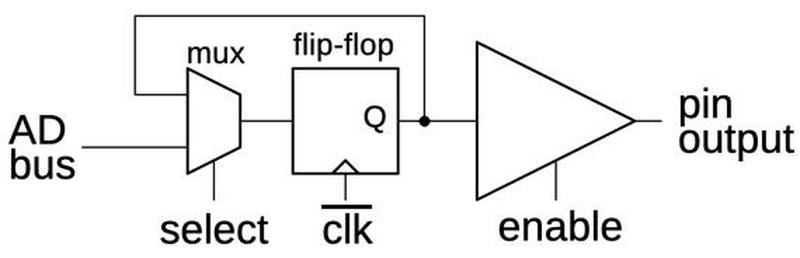

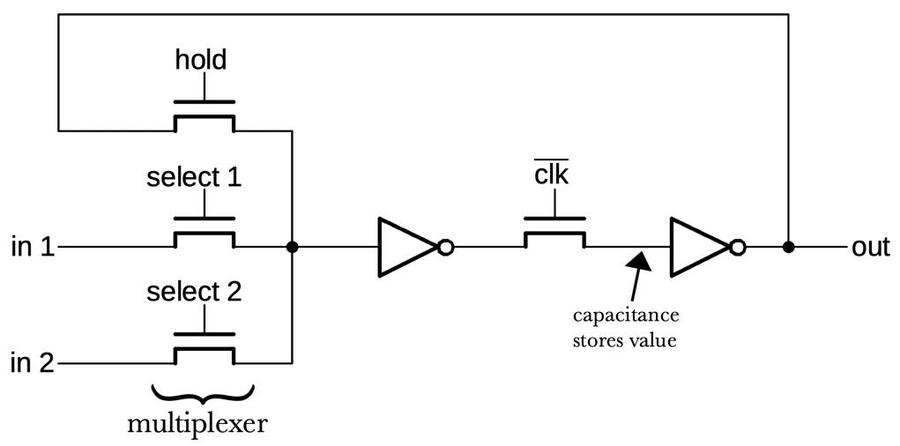

AD4-AD15

Pins AD4-AD15 are "typical" pins, avoiding the special behavior of the top and bottom pins, so I'll discuss them first.

The behavior of these pins is that the value on the AD bus is latched by the circuit and then put on the output pin

under the control of the enaable signal.

The circuit has three parts: a multiplexer to select the output value, a flip-flop to hold the output value, and a tri-state driver to

provide the high-current output to the pin.

In more detail, the multiplexer selects either the value on the AD bus or the current output from the flip-flop.

That is, the multiplexer can either load a new value into the flip-flop or hold the existing value.17

The flip-flop latches the input value on the falling edge of the clock, passing it to the output driver.

If the enable line is high, the output driver puts this value on the corresponding address pin.

For a write, the circuit latches the address value on the bus during the second half of T0 and puts it on the pins during T1.

During the second half of the T1 state, the data word is transferred from the OPR register over the C bus to the AD bus and loaded

into the AD pin latches.

The word is transferred from the latches to the pins during T2 and held for the remainder of the bus cycle.

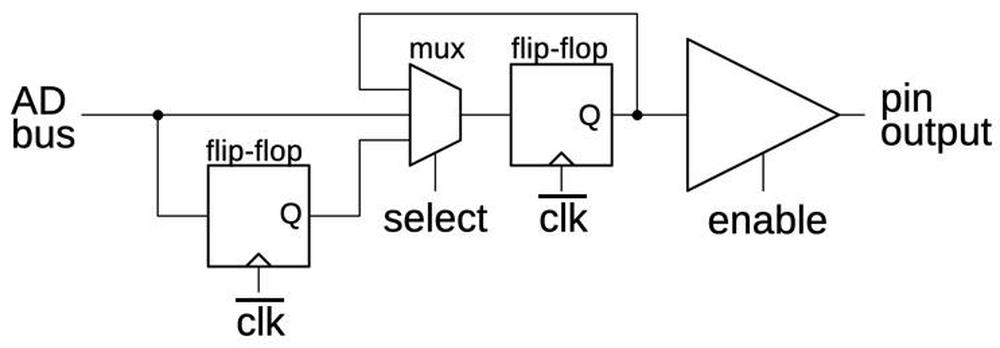

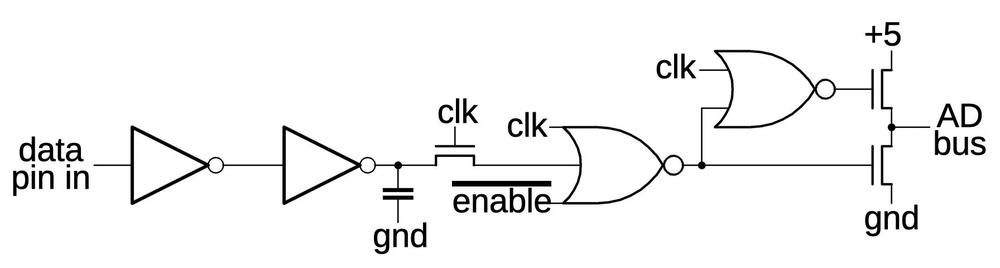

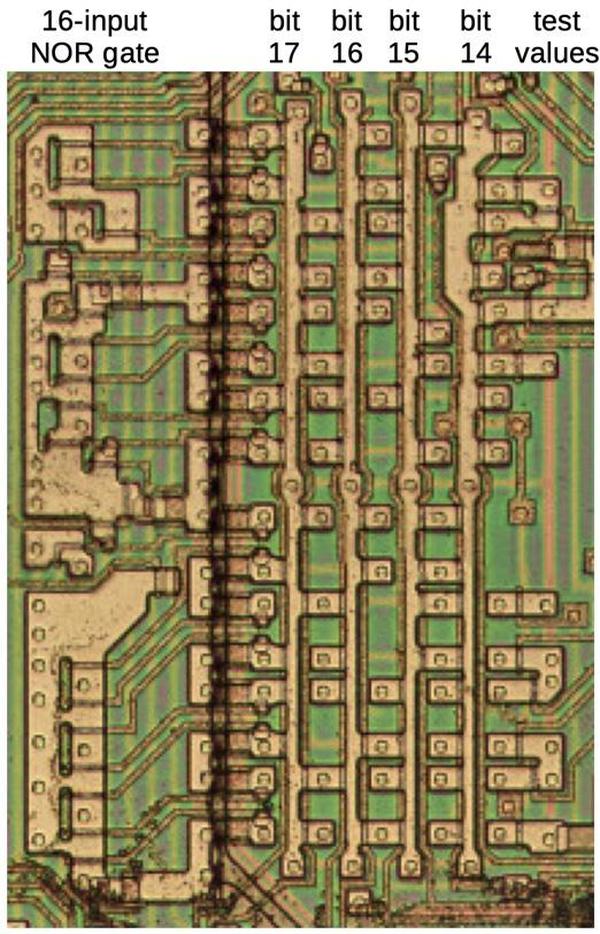

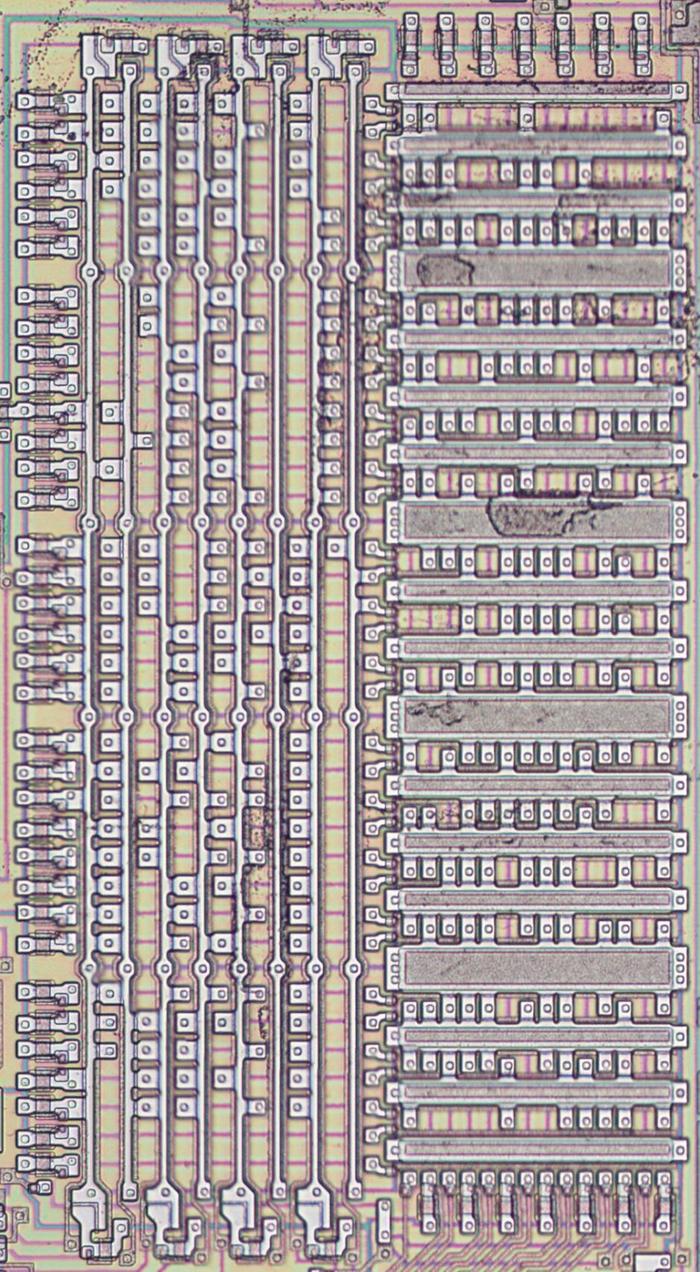

AD0-AD3

The four low address bits have a more complex circuit because these address bits are latched from the bus before the address adder computes its sum, as described earlier. The memory offset (before the segment addition) will be on the C bus during the second half of TS and is loaded into the lower flip-flop. This flip-flop delays these bits for one clock cycle and then they are loaded into the upper flip-flop. Thus, these four pins pick up the offset prior to the addition, while the other pins get the result of the segment addition.

For data, the AD0-AD3 pins transfer data directly from the AD bus to the pin latch, bypassing the delay that was used to get the address bits. That is, the AD0-AD3 pins have two paths: the delayed path used for addresses during T0 and the direct path otherwise used for data. Thus, the multiplexer has three inputs: two for these two paths and a third loop-back input to hold the flip-flop value.

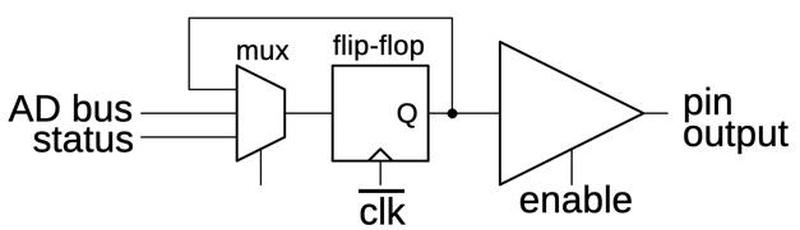

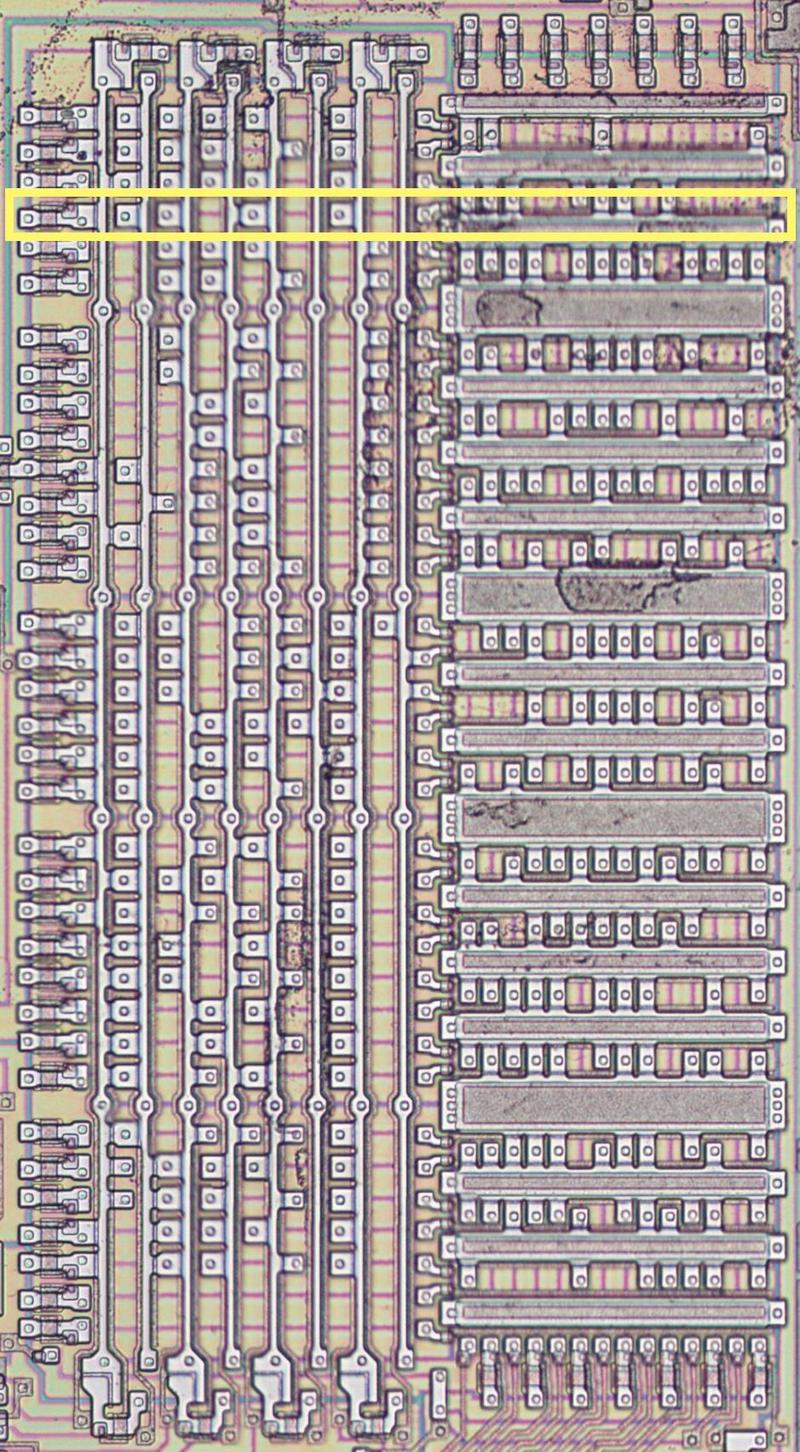

A16-A19: status outputs

The top four pins (A16-A19) are treated specially, since they are not used for data. Instead, they provide processor status during T2-T4.18 The pin latches for these pins are loaded with the address during T0 like the other pins, but loaded with status instead of data during T1. The multiplexer at the input to the latch selects the address bit during T0 and the status bit during T1, and holds the value otherwise. The schematic below shows how this is implemented for A16, A17, and A19.

Address pin A18 is different because it indicates the current status of the interrupt enable flag bit. This status is updated every clock cycle, unlike the other pins. To implement this, the pin has a different circuit that isn't latched, so the status can be updated continuously. The clocked transistors act as "pass transistors", passing the signal through when active. When a pass transistor is turned off, the following logic gate holds the previous value due to the capacitance of the wiring. Thus, the pass transistors provide a way of holding the value through the clock cycle. The flip-flops are implemented with pass transistors internally, so in a sense the circuit below is a flip-flop that has been "exploded" to provide a second path for the interrupt status.

Reads

A memory or I/O read also uses a 4-state bus cycle, slightly different from the write cycle.

During T1, the address is provided on the pins, the same as for a write.

After that, however, the output circuits are tri-stated so they float, allowing the external memory to put data on the bus.

The read data on the pin is put on the AD bus at the start of the T4 state.

From there, the data passes through the crossover circuit to the C bus. Normally the 16 data bits pass straight through to

the C bus, but the bytes will be swapped if the memory access is unaligned.

From the C bus, the data is written to the OPR register, a byte or a word as appropriate.

(For an instruction prefetch, the word is written to a prefetch queue register instead.)

To support data input on the AD0-AD15 pins, they have a circuit to buffer the input data and transfer it to the AD bus. The incoming data bit is buffered by the two inverters and sampled when the clock is high. If the enable' signal is low, the data bit is transferred to the AD bus when the clock is low.19 The two MOSFETs act as a "superbuffer", providing enough current for the fairly long AD bus. I'm not sure what the capacitor accomplishes, maybe avoiding a race condition if the data pin changes just as the clock goes low.20

This circuit has a second role, precharging the AD bus high when the clock is low, if there's no data. Precharging a bus is fairly common in the 8086 (and other NMOS processors) because NMOS transistors are better at pulling a line low than pulling it high. Thus, it's often faster to precharge a line high before it's needed and then pull it low for a 0.21

Since pins A16-A19 are not used for data, they operate the same for reads as for writes: providing address bits and then status.

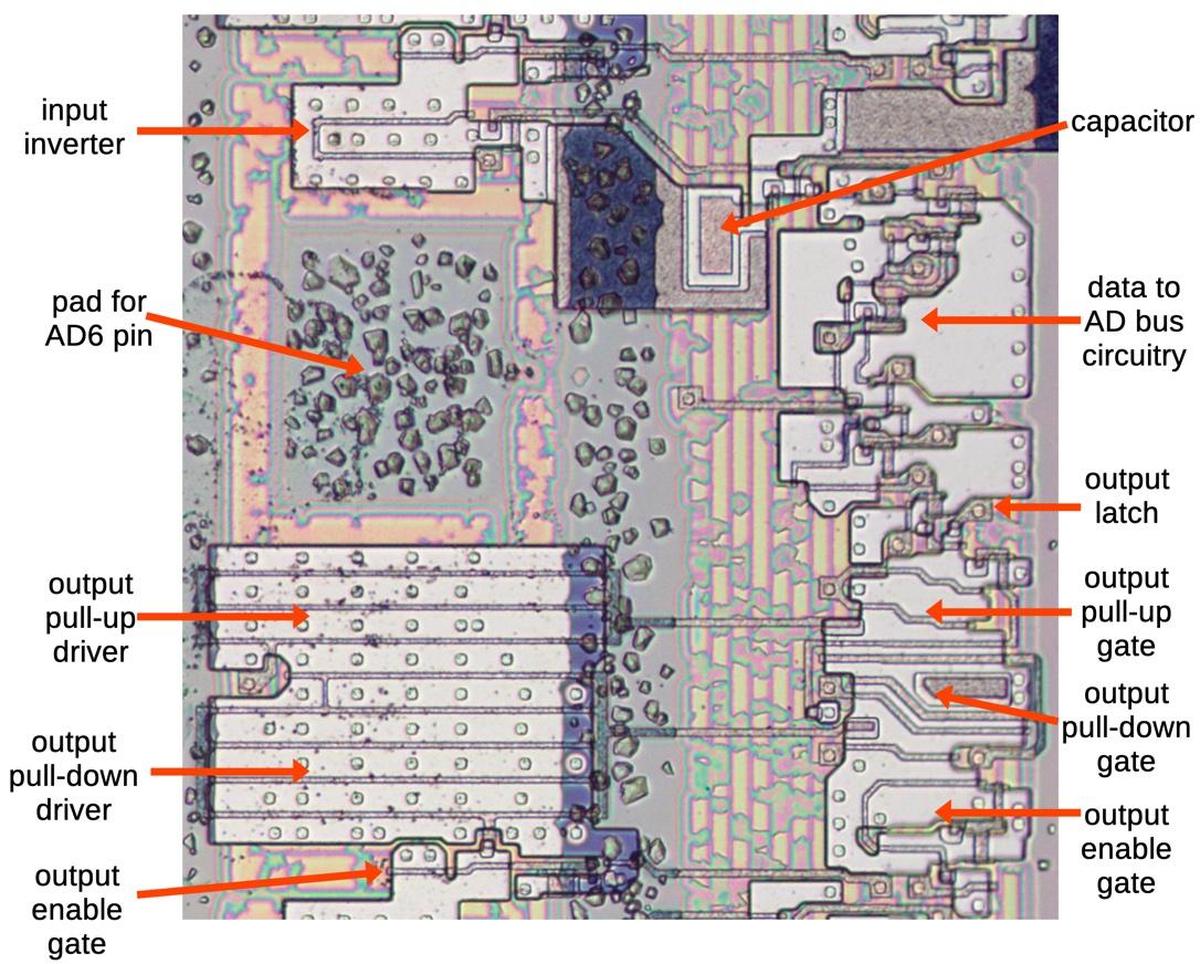

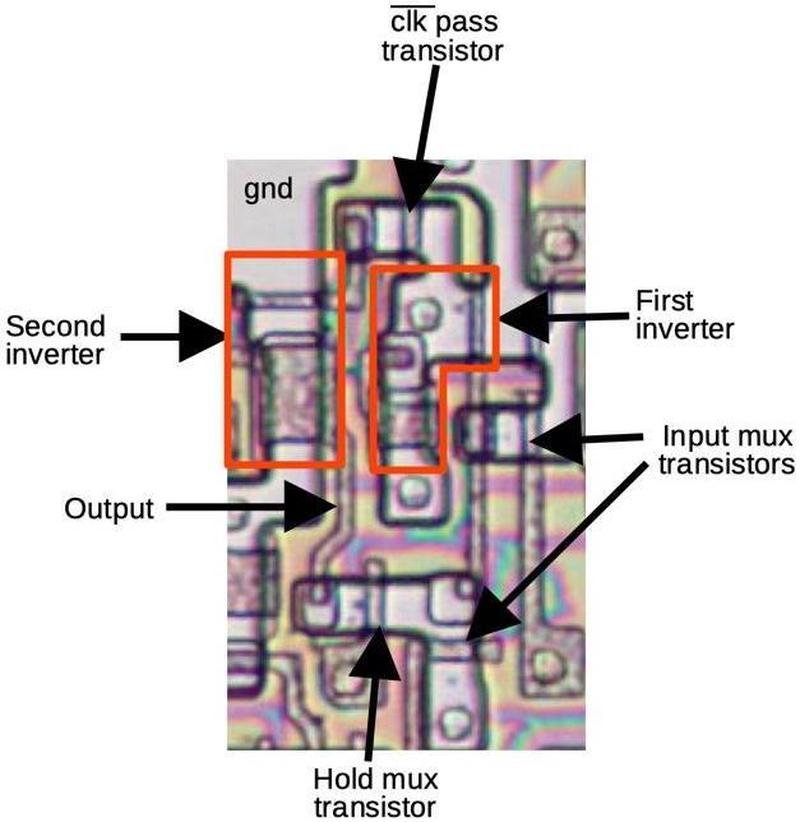

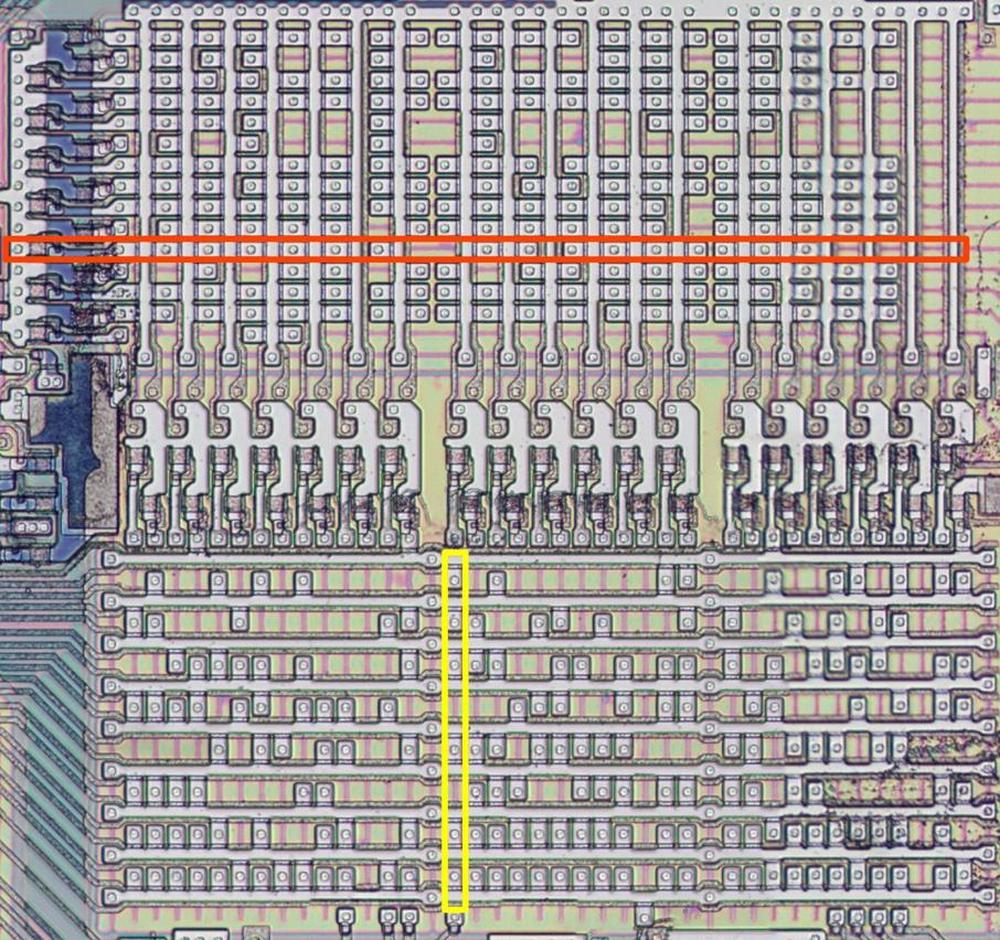

The pin circuit on the die

The diagram below shows how the pin circuitry appears on the die. The metal wiring has been removed to show the silicon and polysilicon. The top half of the image is the input circuitry, reading a data bit from the pin and feeding it to the AD bus. The lower half of the image is the output circuitry, reading an address or data bit from the AD bus and amplifying it for output via the pad. The light gray regions are doped, conductive silicon. The thin tan lines are polysilicon, which forms transistor gates where it crosses doped silicon.

A historical look at pins and timing

The number of pins on Intel chips has grown exponentially, more than a factor of 100 in 50 years. In the early days, Intel management was convinced that a 16-pin package was large enough for any integrated circuit. As a result, the Intel 4004 processor (1971) was crammed into a 16-pin package. Intel chip designer Federico Faggin22 describes 16-pin packages as a completely silly requirement that was throwing away performance, but the "God-given 16 pins" was like a religion at Intel. When Intel was forced to use 18 pins by the 1103 memory chip, it "was like the sky had dropped from heaven" and he had "never seen so many long faces at Intel." Although the 8008 processor (1972) was able to use 18 pins, this low pin count still harmed performance by forcing pins to be used for multiple purposes.

The Intel 8080 (1974) had a larger, 40-pin package that allowed it to have 16 address pins and 8 data pins. Intel stuck with this size for the 8086, even though competitors used larger packages with more pins.23 As processors became more complex, the 40-pin package became infeasible and the pin count rapidly expanded; The 80286 processor (1982) had a 68-pin package, while the i386 (1985) had 132 pins; the i386 needed many more pins because it had a 32-bit data bus and a 24- or 32-bit address bus. The i486 (1989) went to 196 pins while the original Pentium had 273 pins. Nowadays, a modern Core I9 processor uses the FCLGA1700 socket with a whopping 1700 contacts.

Looking at the history of Intel's bus timing, the 8086's complicated memory timing goes back to the Intel 8008 processor (1972). Instruction execution in the 8008 went through a specific sequence of timing states; each clock cycle was assigned a particular state number. Memory accesses took three cycles: the address was sent to memory during states T1 and T2, half of the address at a time since there were only 8 address pins. During state T3, a data byte was either transmitted to memory or read from memory. Instruction execution took place during T4 and T5. State signals from the 8008 chip indicated which state it was in.

The 8080 used an even more complicated timing system. An instruction consisted of one to five "machine cycles", numbered M1 through M5, where each machine cycle corresponded to a memory or I/O access. Each machine cycle consisted of three to five states, T1 through T5, similar to the 8008 states. The 8080 had 10 different types of machine cycle such as instruction fetch, memory read, memory write, stack read or write, or I/O read or write. The status bits indicated the type of machine cycle. The 8086 kept the T1 through T4 memory cycle. Because the 8086 decoupled instruction prefetching from execution, it no longer had explicit M machine cycles. Instead, it used status bits to indicate 8 types of bus activity such as instruction fetch, read data, or write I/O.

Conclusions

Well, address pins is another subject that I thought would be straightforward to explain but turned out to be surprisingly complicated. Many of the 8086's design decisions combine in the address pins: segmented addressing, backward compatibility, and the small 40-pin package. Moreover, because memory accesses are critical to performance, Intel put a lot of effort into this circuitry. Thus, the pin circuitry is tuned for particular purposes, especially pin A18 which is different from all the rest.

There is a lot more to say about memory accesses and how the 8086's Bus Interface Unit performs them. The process is very complicated, with interacting state machines for memory operation and instruction prefetches, as well as handling unaligned memory accesses. I plan to write more, so follow me on Twitter @kenshirriff or RSS for updates. I've also started experimenting with Mastodon recently as @kenshirriff@oldbytes.space and Bluesky as @righto.com so you can follow me there too.

Notes and references

-

In the discussion, I'll often call all the address pins "AD" pins for simplicity, even though pins 16-19 are not used for data. ↩

-

The 8086's compatibility with the 8080 was somewhat limited since the 8086 had a different instruction set. However, Intel provided a conversion program called CONV86 that could convert 8080/8085 assembly code into 8086 assembly code that would usually work after minor editing. The 8086 was designed to make this process straightforward, with a mapping from the 8080's registers onto the 8086's registers, along with a mostly-compatible instruction set. (There were a few 8080 instructions that would be expanded into multiple 8086 instructions.) The conversion worked for straightforward code, but didn't work well with tricky, self-modifying code, for instance. ↩

-

To support the 8086's segment architecture, programmers needed to deal with "near" and "far" pointers. A near pointer consisted of a 16-bit offset and could access 64K in a segment. A far pointer consisted of a 16-bit offset along with a 16-bit segment address. By modifying the segment register on each access, the full megabyte of memory could be accessed. The drawbacks were that far pointers were twice as big and were slower. ↩

-